Device for preventing photoresist backflow and using method thereof

A photoresist and photoresist bottle technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as photoresist reflow, and achieve the effects of less increase, convenient operation, and improved cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

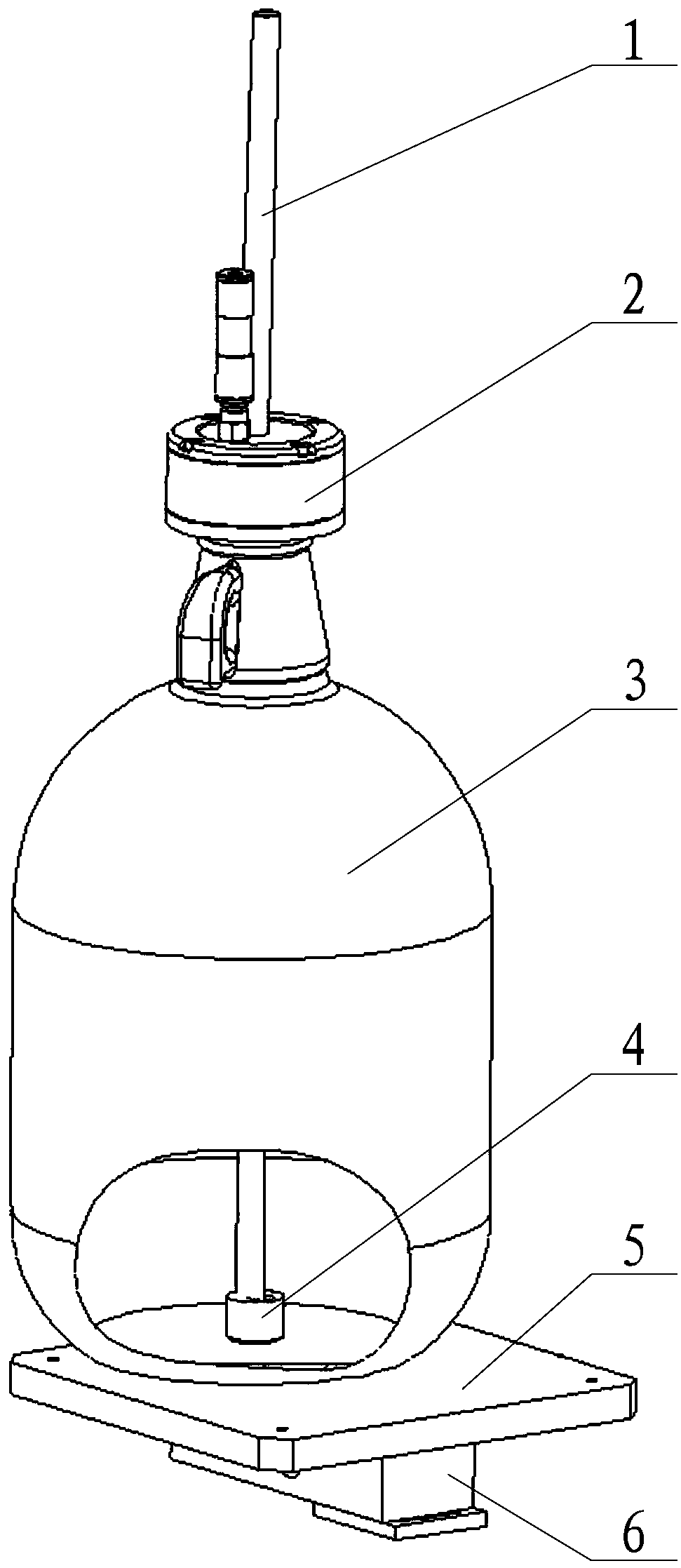

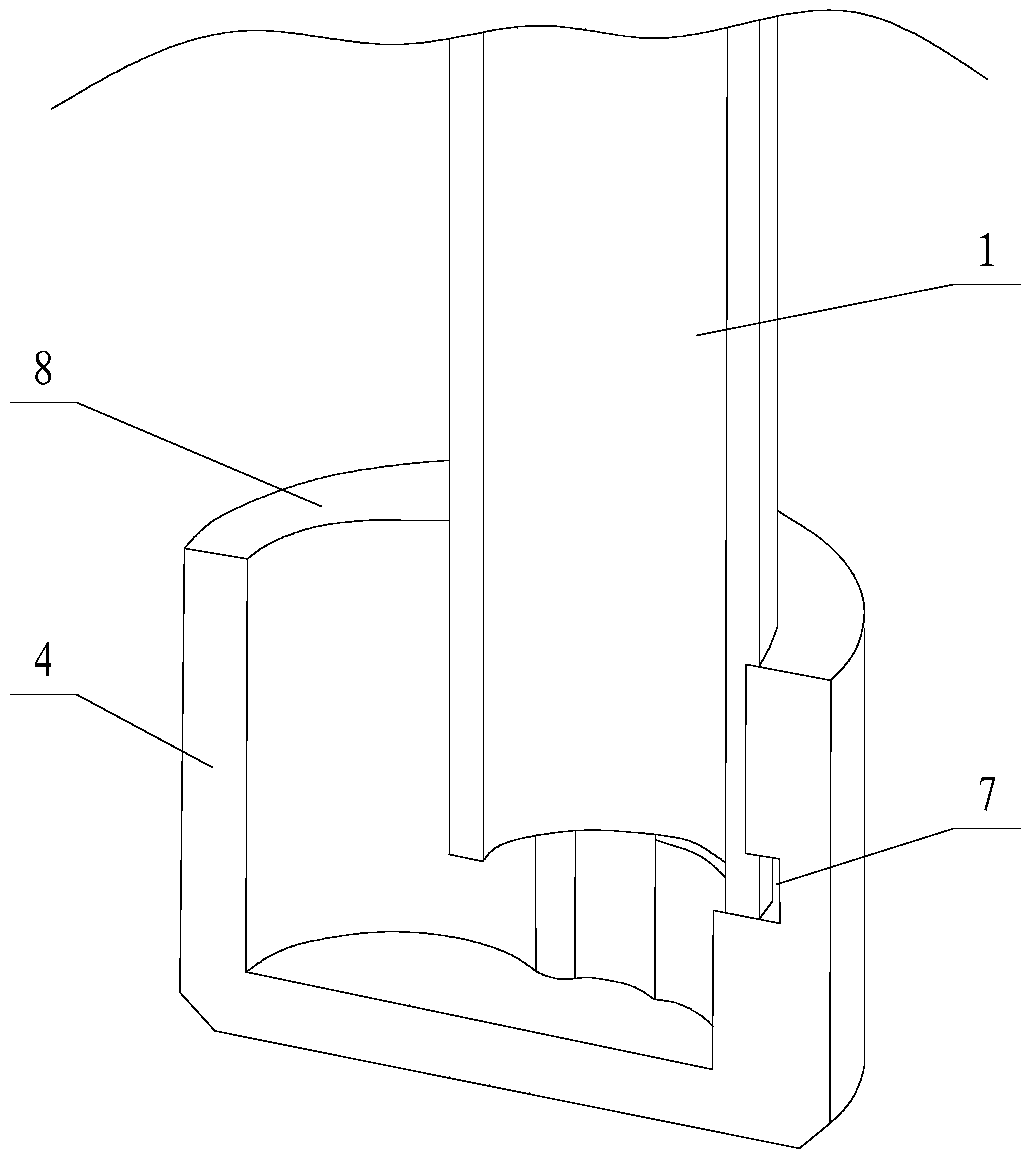

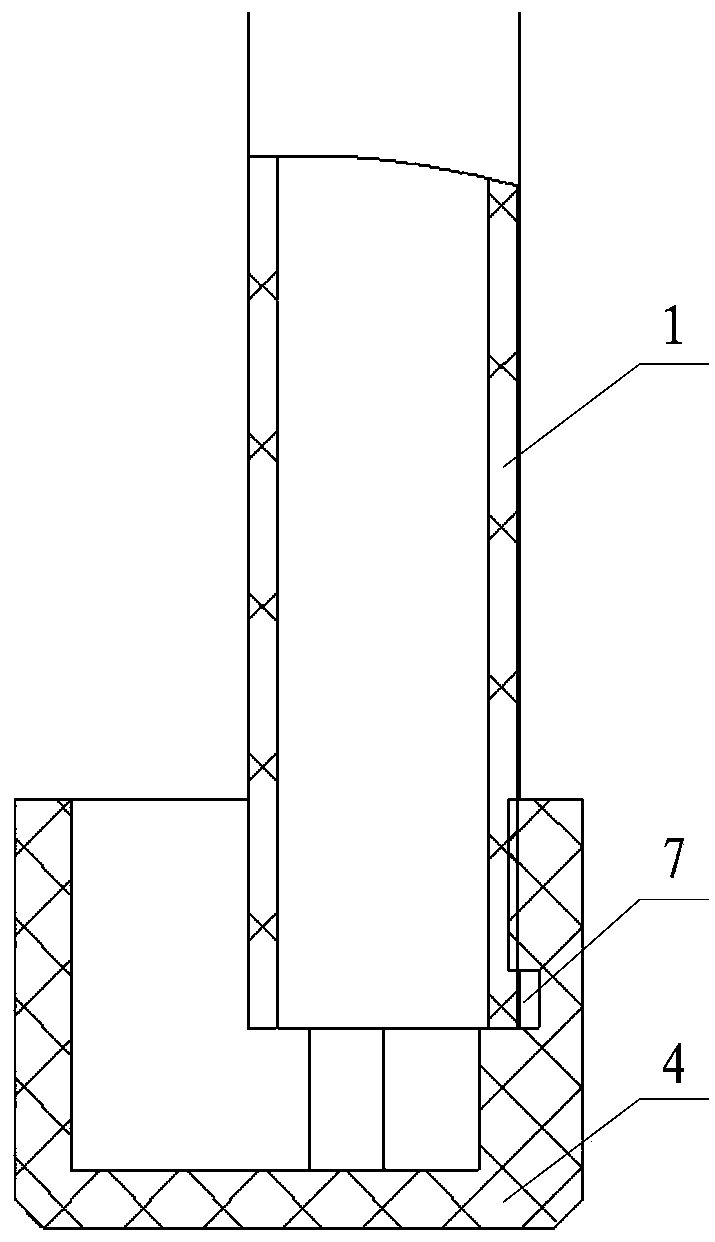

[0021] Such as Figure 1~3 As shown, the device for preventing photoresist reflux of the present invention includes a photoresist pipeline 1, a photoresist bottle cap 2, a photoresist bottle 3, an air-proof pipe plug 4, a photoresist bottle supporting plate 5 and a load cell 6, wherein the photoresist bottle 3 is placed on the photoresist bottle supporting board 5, and the bottom of the photoresist bottle supporting board 5 is equipped with a weighing sensor 6.

[0022] The photoresist pipeline 1 is fixedly installed on the photoresist bottle cap 2, and then installed on the photoresist bottle 3 together with the photoresist bottle cap 2; the end of the photoresist pipeline 1 extends into the photoresist bottle 3, and the photoresist tube The length of the road 1 extending into the photoresist bottle 3 can be adjusted; the end of the photoresist line 1 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com