Control chip mounting base of control system

A technology for controlling chips and control systems, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of uneven force on the chip, troublesome operation, damage, etc., to achieve easy replacement, easy disassembly, and avoid pin looseness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

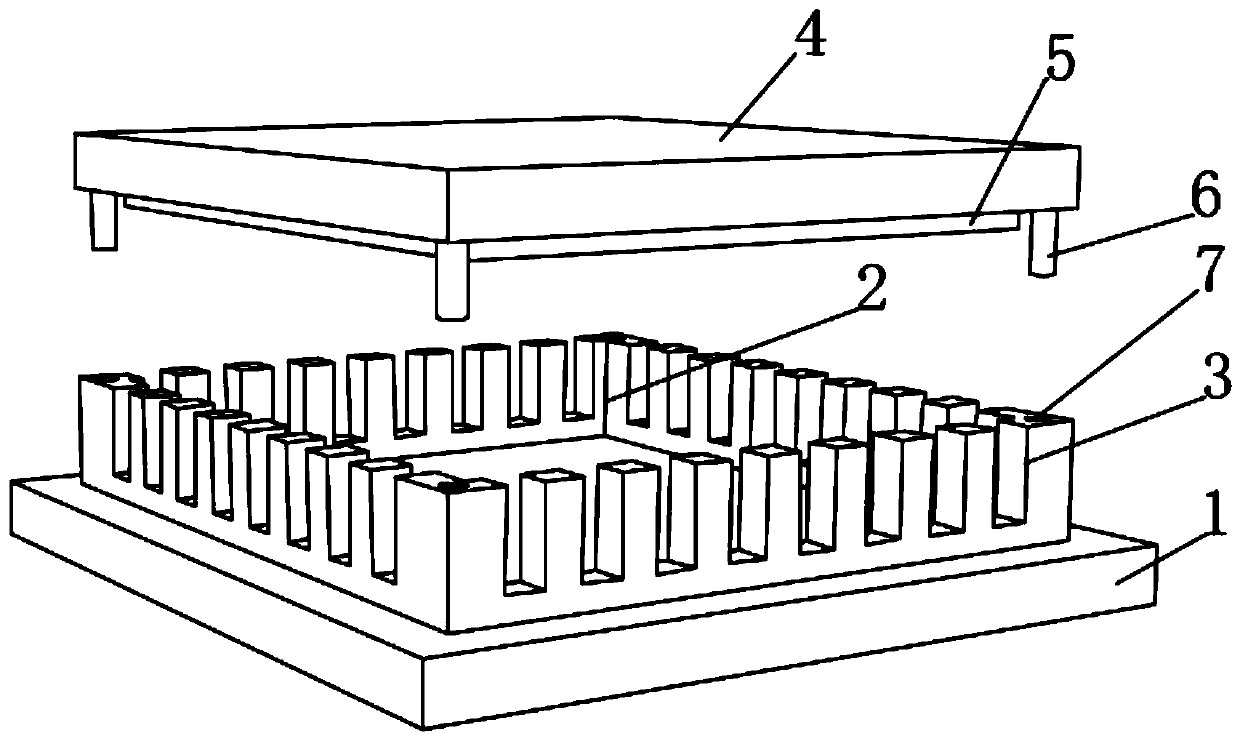

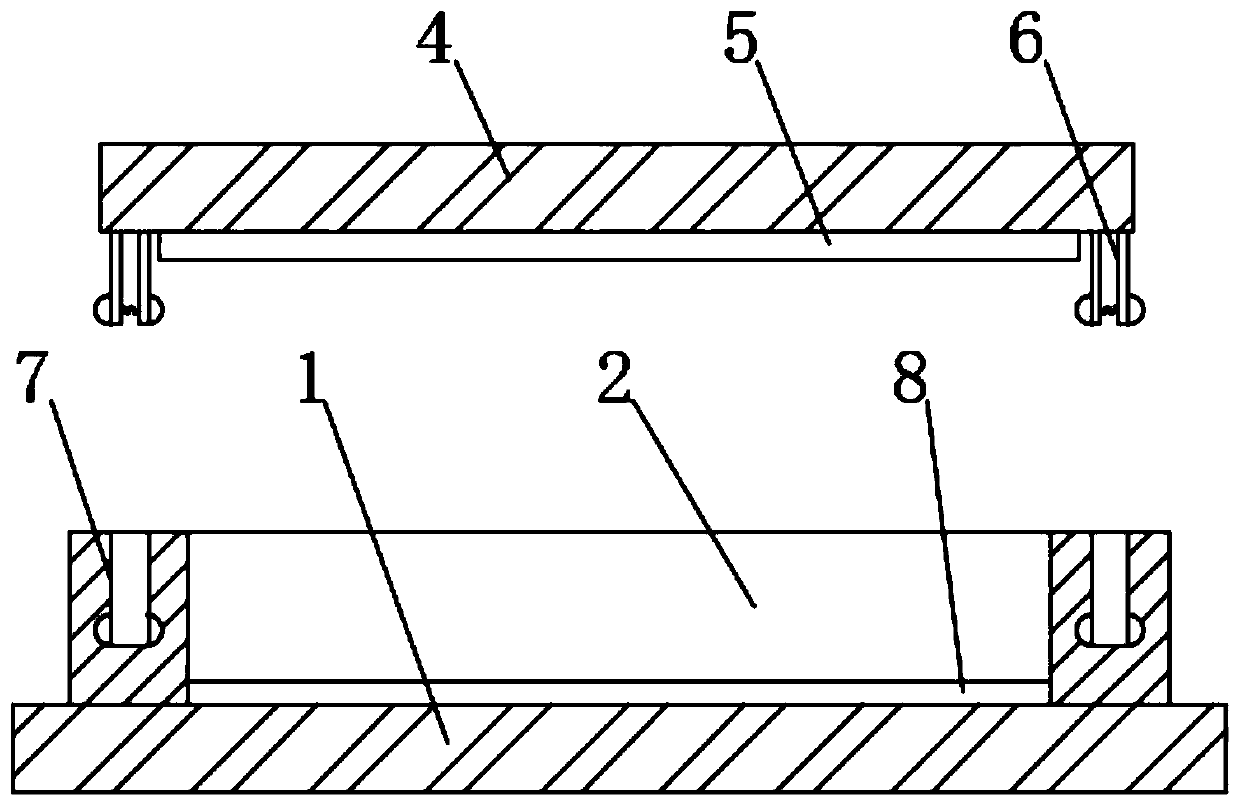

[0028] As attached Figure 1-2 The control chip mounting seat of a control system of the present invention shown includes a base 1 and a mounting plate fixedly connected to the upper end of the base 1. A mounting groove 2 is excavated inside the mounting plate, and a plurality of evenly distributed mounting plates are excavated around the mounting plate. Pin slot 3, a cover plate 4 is provided above the base 1. The four corners of the lower end of the cover plate 4 are fixedly connected with positioning posts 6, and the four corners of the upper end of the mounting plate are cut with positioning slots 7 matching the positioning posts 6. The lower end of the cover plate 4 is fixedly connected with a heat conduction plate 5, and a plurality of evenly distributed heat dissipation holes are excavated on the cover plate 4. The heat conduction plate 5 can promptly guide the heat generated by the chip in the working process upward, and then discharge it upward through the heat dissipat...

Embodiment 2

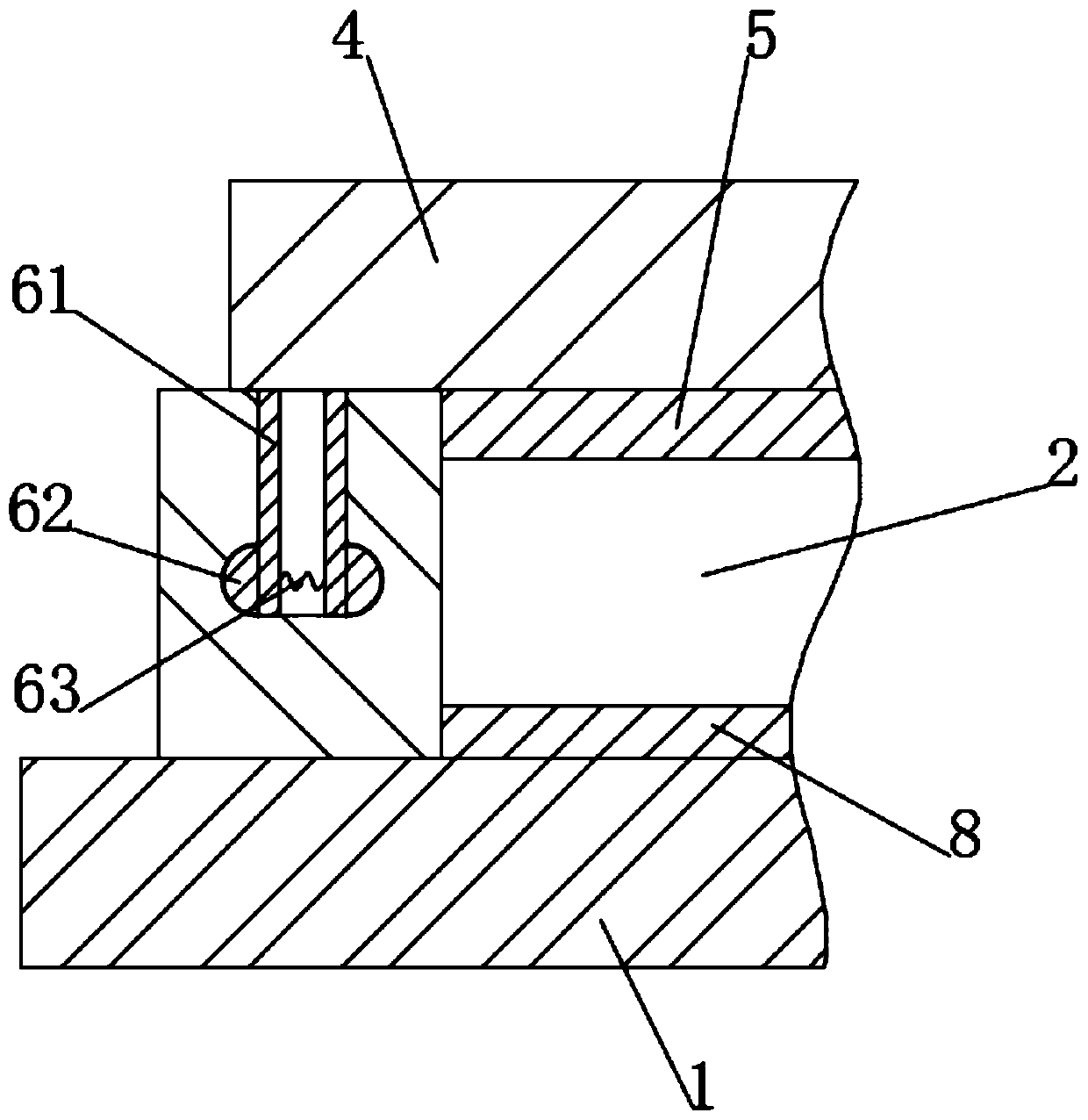

[0032] As attached image 3 The shrapnel 61 can also be arranged in a cylindrical structure on the outer surface, and the cross section of the inner surface of the shrapnel 61 is set up with a small lower and a large slope, which effectively ensures that when the positioning pillar 6 is inserted into the positioning groove 7, the two shrapnel 61 are squeezed After pressing, there can be a certain inward squeezing space, which is convenient for insertion and extraction.

[0033] When installing the chip, first align the pins of the chip with the pin slot 3, place the chip in the mounting slot 2, and then align the positioning column 6 on the cover 4 with the positioning slot 7 and press down so that the chip is fixed in the mounting slot. In slot 2, when disassembling the chip, first press the pressing rod 10 manually or through the frame of the back shape, and then pull the cover plate 4 upward through the pull ring 9 to separate the cover plate 4 from the mounting plate, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com