Current type control system and method for three-state step-down switching power supply

A switching power supply and control system technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve rare, complex loop control, complex control and other problems, achieve small inductor size, small device electrical stress, transient response quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

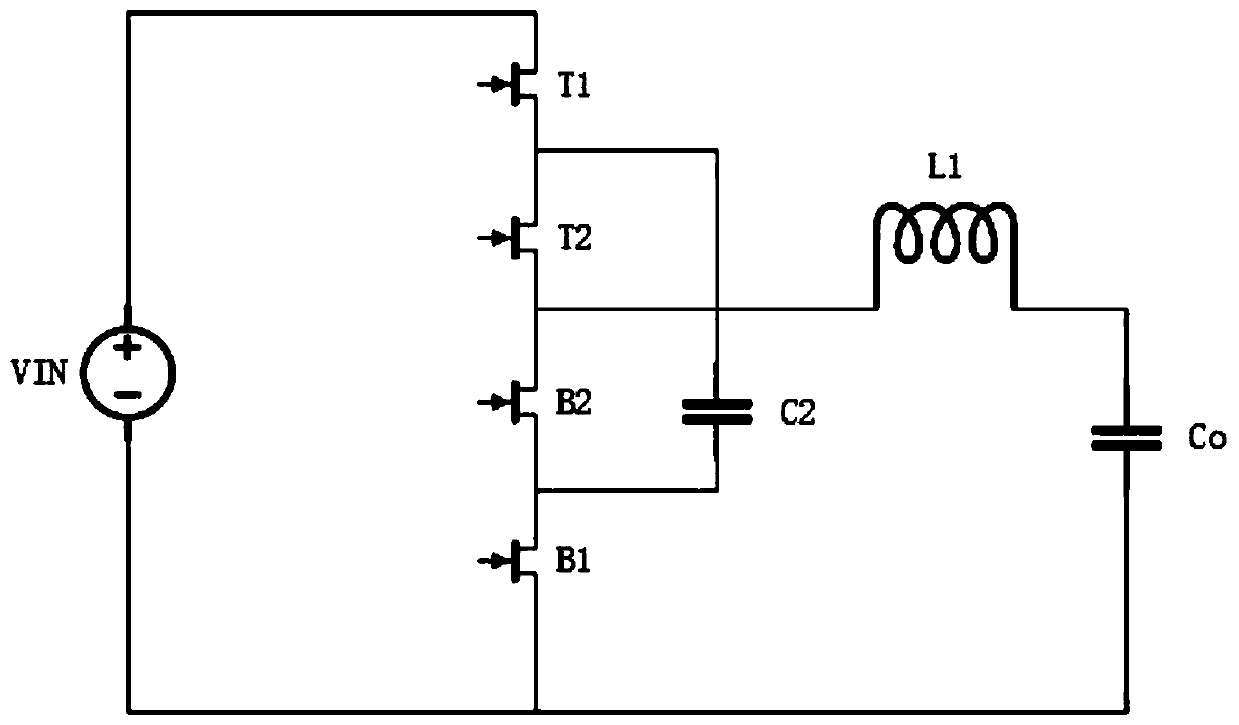

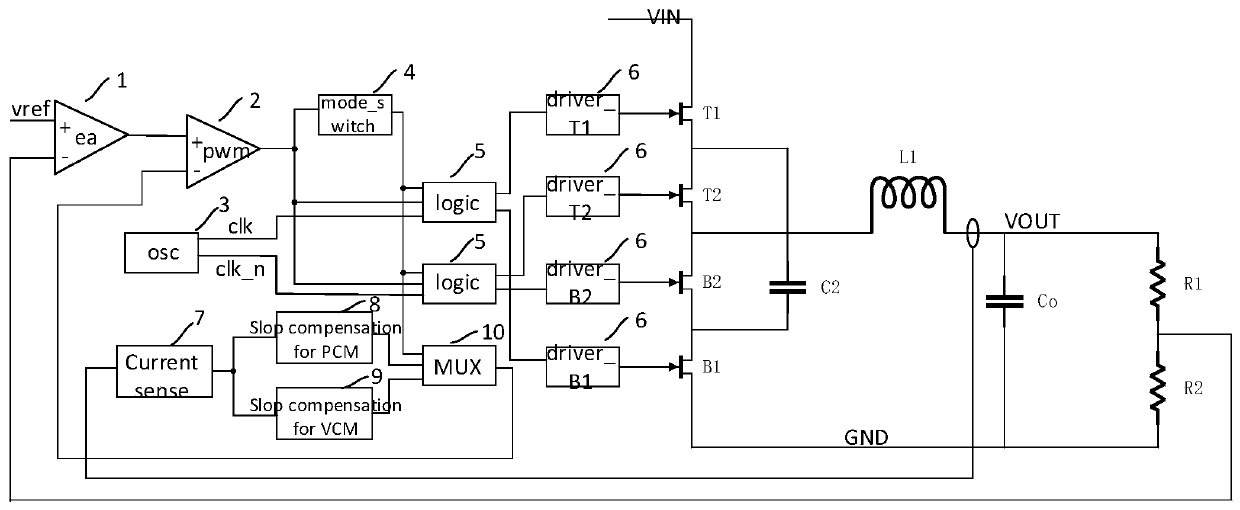

[0026] A current-type three-state step-down switching power supply control system, including a first upper power transistor T1 and a corresponding first lower power transistor B1 arranged on a voltage source circuit, and also includes a first upper power transistor T1 and a first lower power transistor B1 arranged on a voltage source circuit. The second upper power tube T2 between the lower power tubes B1 and the corresponding second lower power tube B2, a mode selector (modeswitch) 4, and a logic control module 6;

[0027] The mode selector 4 is used to select the working state of the peak current mode PCM or the valley current mode VCM; the mode selection can be realized by using the existing technology;

[0028] The logic control module 6 is used to control the opening and closing of the power tube under the peak current mode PCM and the valley current mode VCM; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com