Molds and Forming Systems

A technology for molds and molded products, which is applied in the field of molds and molding systems, and can solve the problems of easily insufficient release agent, time-consuming, and rapid cooling of the mold surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

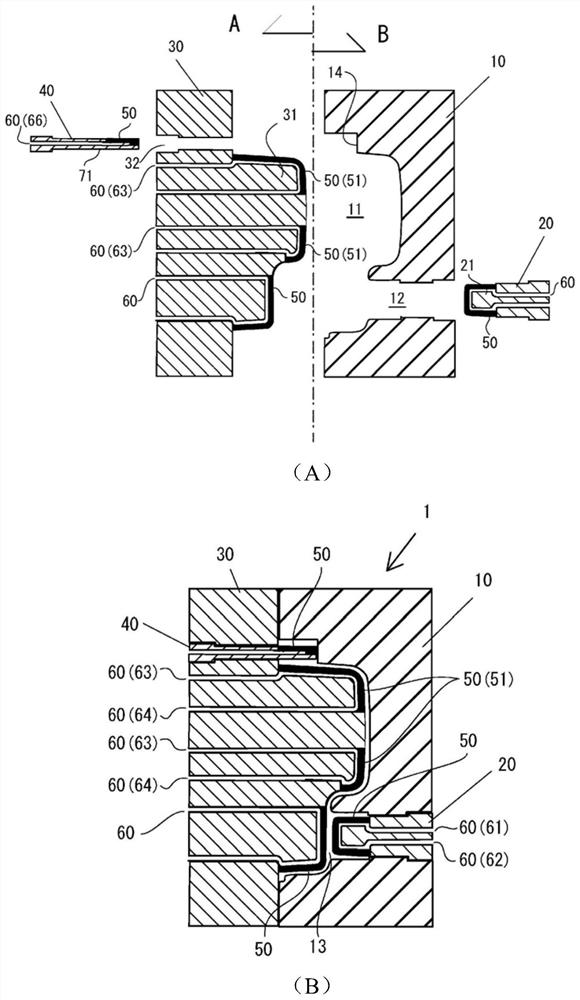

[0076] In the first embodiment, refer to figure 1 , figure 2 , the mold 1 in which the low-density region is formed along the surface of the protruding portion of each inner surface of a pair of molds is described. figure 1 (A) is an explanatory diagram illustrating the structure of the mold through a cross-section, figure 1 (B) is an explanatory diagram illustrating a state in which a pair of molds are brought into contact with each other through a cross section. figure 2 (A) in shows figure 1 A side view of the movable mold viewed from the direction A of (A), figure 2 (B) in shows figure 1 A side view of the fixed mold viewed from the B direction in (A). In addition, in figure 2 In , the phantom line of the liquid path portion is shown by a dotted line.

[0077] The mold 1 of the first embodiment is composed of a fixed mold and a movable mold. The fixed mold is composed of a fixed mold main body 10 and a fixed mold part 20. A concave part 11 is formed in the cen...

no. 2 example

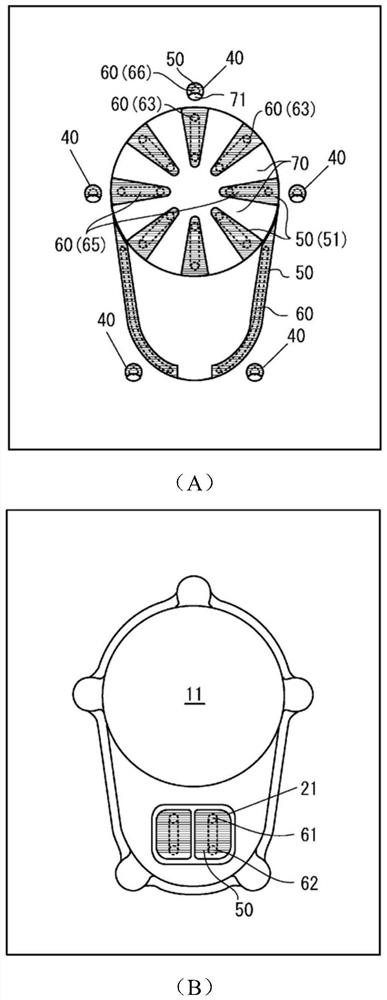

[0092] In the second embodiment, refer to image 3 , the movable mold of the mold 2 in which the low-density region portion is formed in a mode different from that of the first embodiment will be briefly described. image 3 (A) in (A) shows the sectional view of mold 2, image 3 (B) in (B) shows the side view seen from the inner surface of a movable mold. Since the fixed mold can be made the same as the movable mold, only the form of the fixed mold is shown with a dotted line, and description is omitted. In addition, since the liquid path part can be made the same as the mold 1 of 1st Example, the same code|symbol is attached|subjected in drawing, and description is abbreviate|omitted.

[0093] The movable mold main body of the mold 2 is the same as the mold 1, and the protruding part 31 is formed so as to form a step. The entire peripheral surface of the protruding portion 31 formed to form a step in the movable mold body of the mold 2 is covered with the low-density area ...

no. 3 example

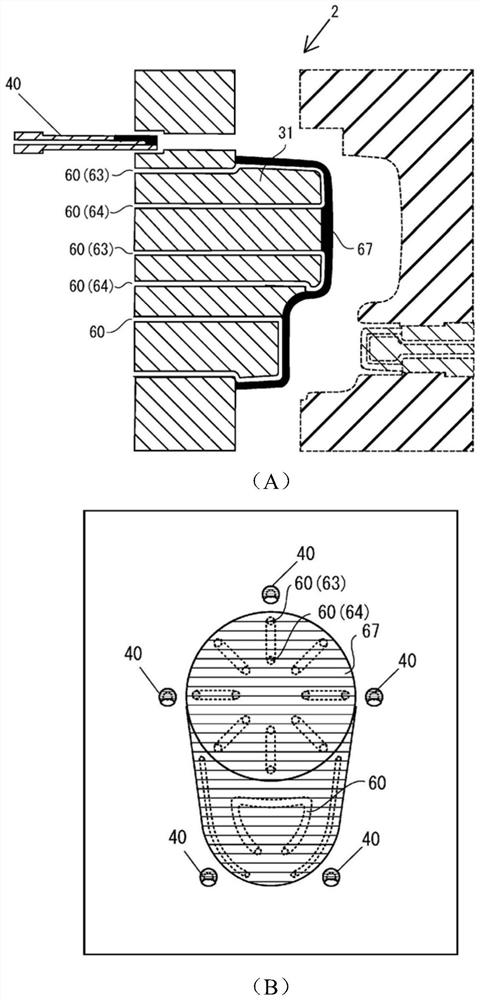

[0095] In the third embodiment, referring to Figure 4 , the mold 3 which is different from the structure of the low-density region portion and the liquid path portion on the surface of the front step portion of the protruding portion 31 of the movable mold member of the first embodiment will be described. On the surface of the front step portion of the mold 3, low-density region portions 52 of a predetermined width are arranged along three concentric circles arranged at equal intervals. Figure 4 (A) shows a side view viewed from the inside of the front step portion of the protruding portion of the mold 3, Figure 4 (B) in (B) is an explanatory drawing explaining a liquid path part. Figure 4 (C) in the front step is Figure 4 (A) Explanatory drawing of the cross-sectional view at A position.

[0096] Tubes having a rectangular cross-section in contact with the inner surfaces of the low-density region portions 52 arranged along three concentric circles are disposed so as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com