Impeller, emulsifying pump and emulsifying system

An emulsification pump and impeller technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of small suction lift and lift, and achieve the effect of increasing suction lift, increasing vacuum degree, and increasing lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

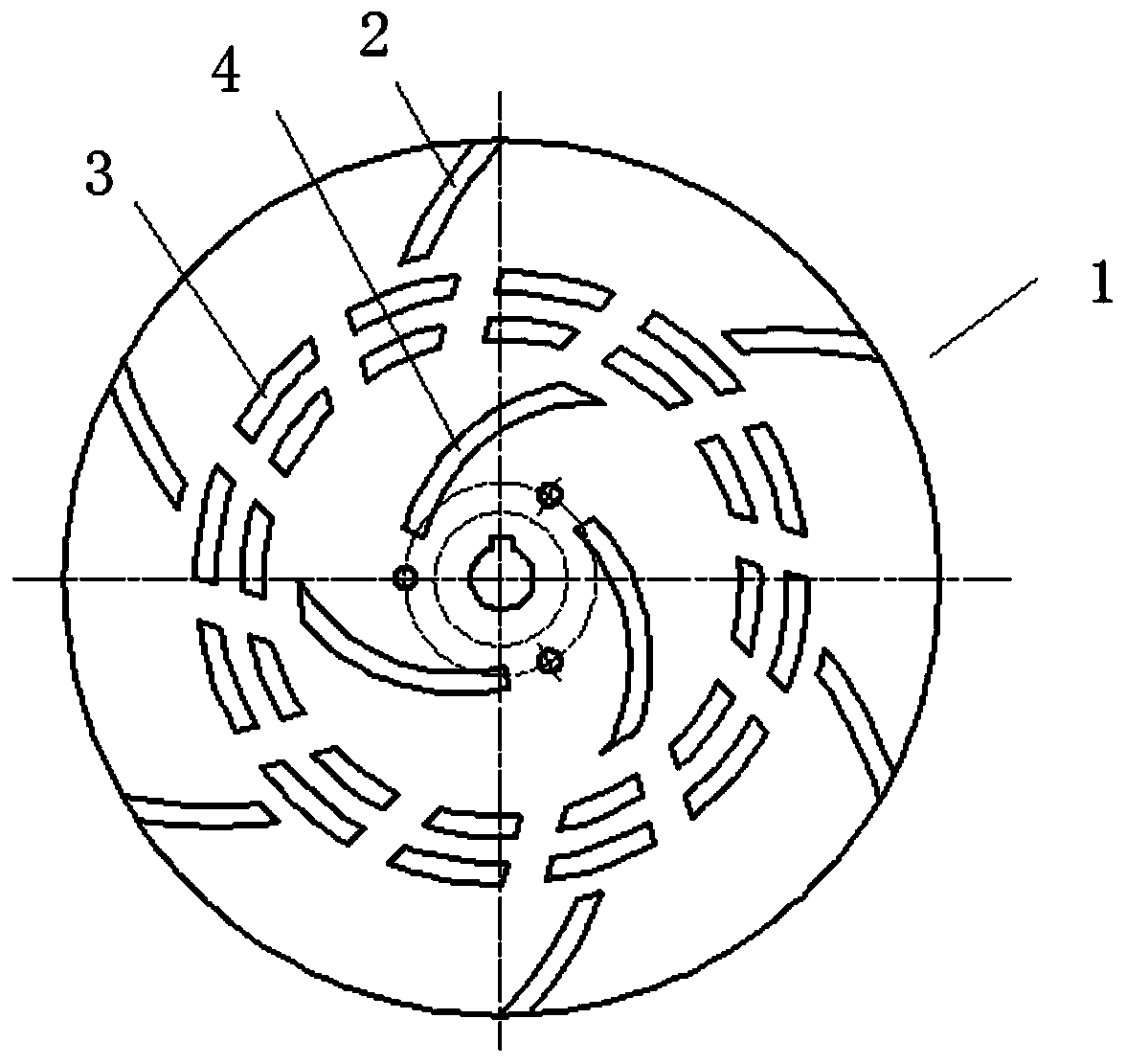

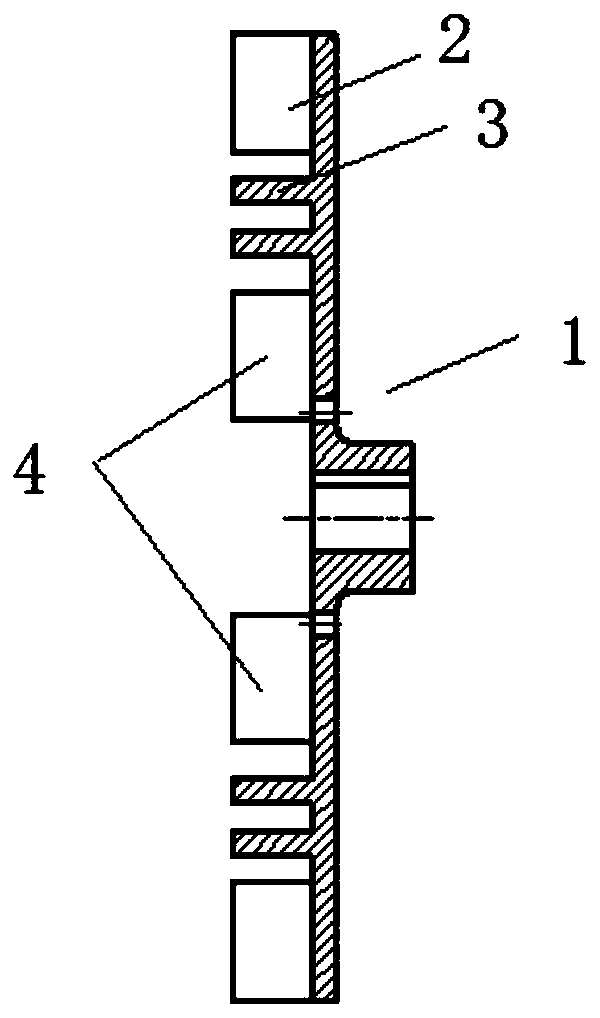

[0029] The impeller in this embodiment, such as figure 1 and figure 2 As shown, it includes a stator, and a rotor 1 coupled with the stator, and the rotor 1 is provided with a range-extending assembly for increasing suction and lift.

[0030] The range extender assembly has multiple turns around the axis of the rotor 1. In this embodiment, the range extender assembly includes a first range extender assembly located on the outer ring of the rotor 1, and a second range extender assembly located on the inner ring of the rotor 1. Two range extender components, between the first range extender component and the second range extender component, multiple turns of the shear piece 3 of the rotor 1 are arranged.

[0031] The number of turns of the shearing piece 3 on the rotor 1 needs to be set according to the usage requirements, but it is required that the number of the shearing piece 3 on the rotor 1 corresponds to the number of teeth on the stator overlapping with the shearing pie...

Embodiment 2

[0036] The emulsification pump in this embodiment has the impeller in Embodiment 1, so the emulsification pump has the advantages of large suction and lift and relatively low cost of use.

Embodiment 3

[0038] The emulsification system in this embodiment has the emulsification pump described in Embodiment 2. Since the emulsification pump has a relatively large suction and lift, the emulsification system is relatively simplified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com