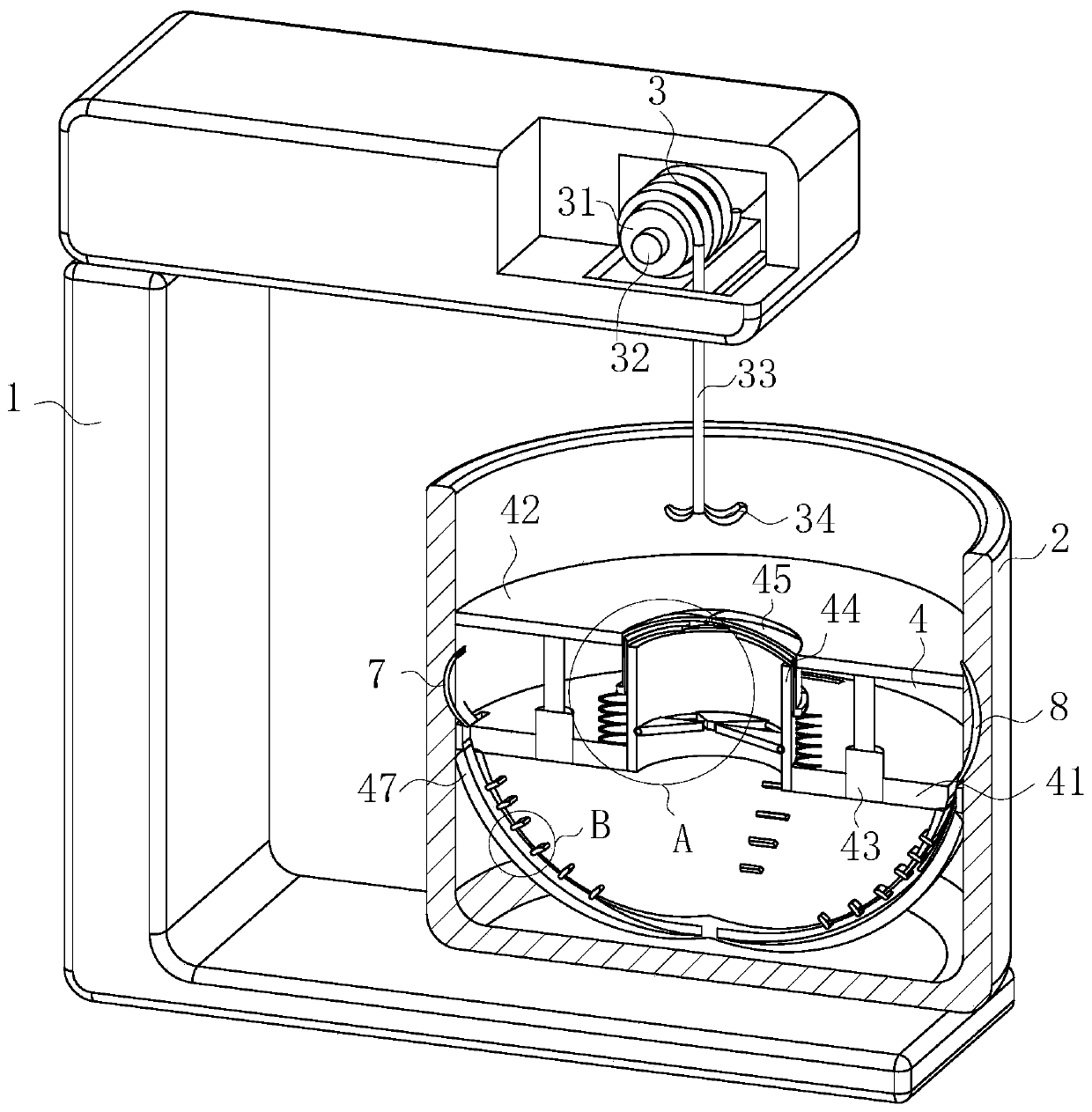

Optical nickel plating machine

An optical plating and nickel plating technology, applied in liquid chemical plating, dryers, local stirring dryers, etc., can solve the problem of reducing the effect of nickel plating on small batches or small workpieces, affecting the efficiency of nickel plating, and large equipment. problem, to achieve the effect of increasing drying effect, simple structure and increasing utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

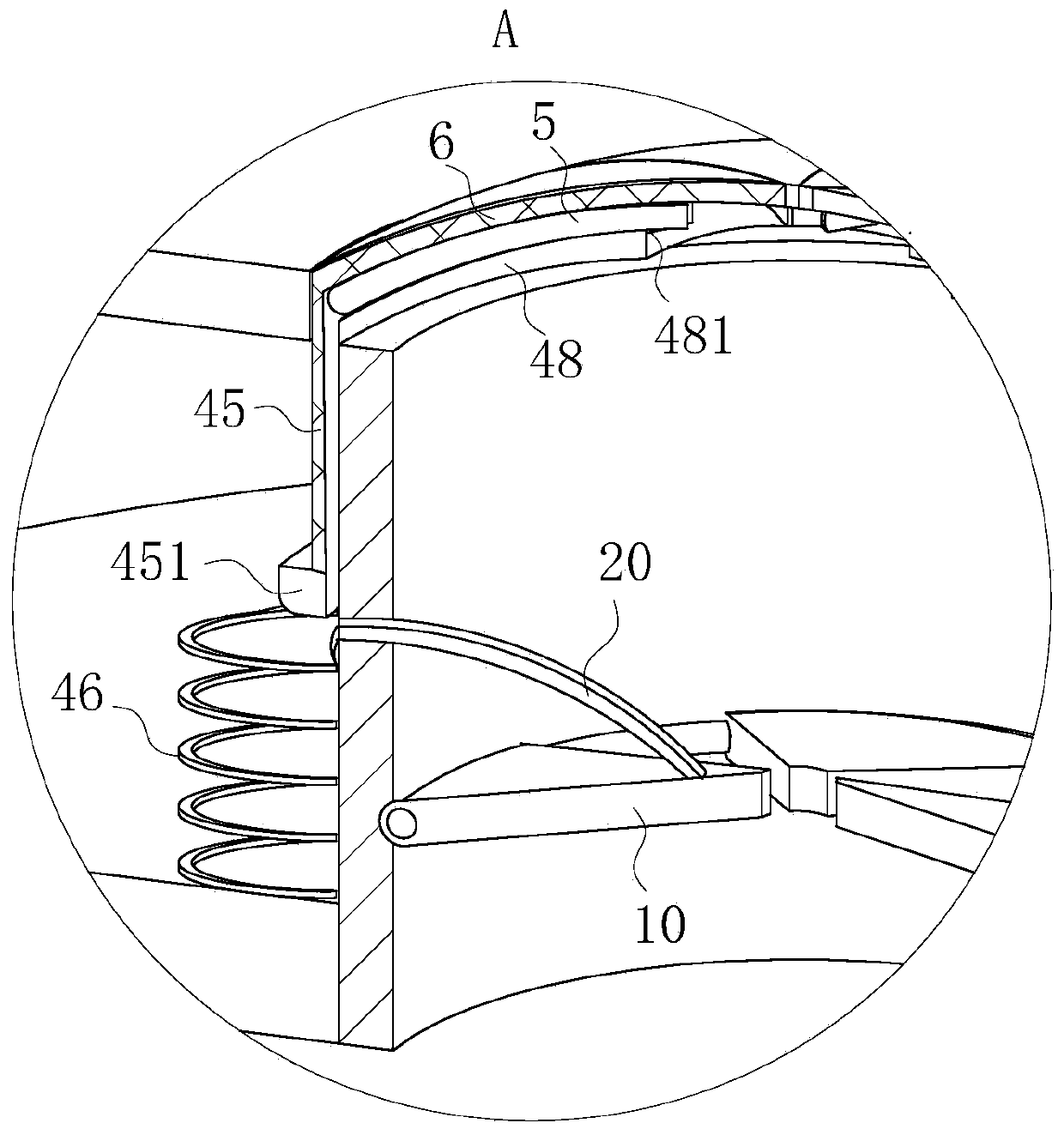

[0023] As an embodiment of the present invention, a plurality of T-shaped guide grooves 481 are opened on the arched guide plate 48, and the plurality of T-shaped guide grooves 481 correspond to the plurality of rubber sealing plates 45; The bottom end of the plate 45 is provided with a T-shaped rubber slide bar 5, and the T-shaped rubber slide bar 5 and the T-shaped guide groove are mutually slidingly arranged; When sliding, the T-shaped rubber slide bar 5 provided at the bottom of the rubber sealing plate 45 can slide down along the T-shaped guide groove, and then the T-shaped rubber slide bar 5 and the T-shaped guide groove slide and cooperate with each other, which can prevent the rubber seal plate from being When 45 slides downward or upward, the downward extrusion force of deflector 42 or the upward reaction force of limit spring 46 both act on the bottom end of rubber sealing plate 45, causing the top end of rubber sealing plate 45 to warp , thereby affecting the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com