Intelligent concrete distribution control system and method for transverse folding arm concrete spreader

A control system and concrete technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of no relevant technical reference materials, increase labor costs, low level of industrialization of placing machines, etc., to improve pouring quality and save money. Labor costs, the effect of improving the level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

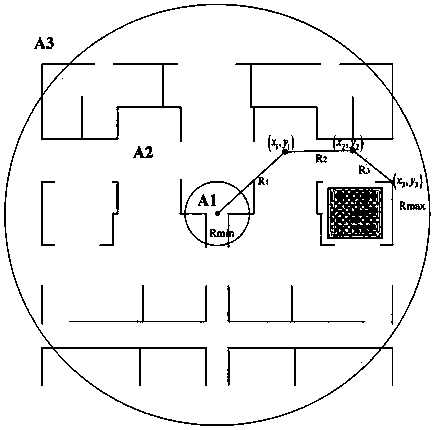

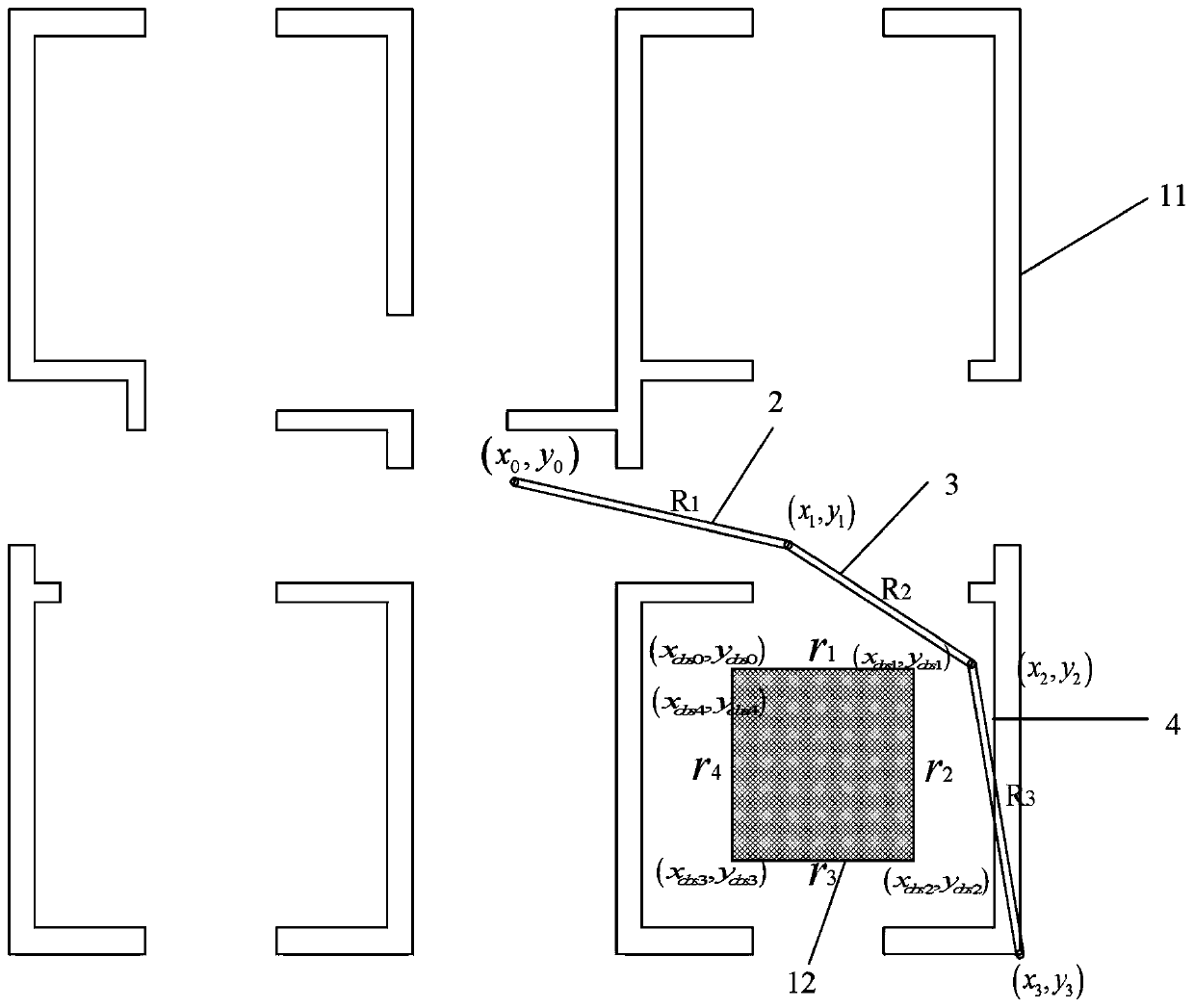

[0062] This embodiment mainly discloses a method for planning a distribution path of a cross-boom concrete distributor. Combine Figure 1 to Figure 6 Give a further explanation.

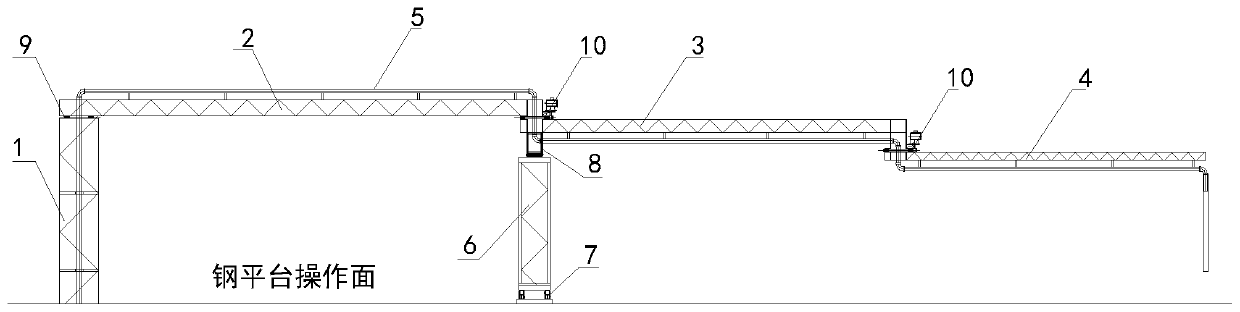

[0063] figure 1 Disclosed is a schematic structural diagram of a horizontal folding arm distributor, which includes a main tower 1, a plurality of booms connected in sequence, a pump tube 5, a supporting tower 6, a walking mechanism 7 and a rotating bracket 8. figure 1 with figure 2 The cloth machine shown in has three booms, which are respectively marked as the first boom 2, the second boom 3 and the third boom 4. Of course, the number here does not constitute a limitation to the present invention. The main tower 1 and the first boom 2 and the adjacent booms can be horizontally rotatably connected. As an example, the main tower 1 and the first boom 2 are connected by a first slewing mechanism 9, and adjacent booms are connected by a second slewing mechanism 10. The first slewing mechanism 9 is a dri...

Embodiment 2

[0096] This embodiment discloses an intelligent distributing control system for a cross-folding arm concrete distributor. First, the basic structure of the distributor is introduced. The distributor includes a main tower and M booms spliced in sequence; the first arm A slewing mechanism is arranged between the main tower and the main tower and between two adjacent booms; it also includes a pump tube that is arranged along the main tower and the boom, and is connected between the main tower and the first The connection of the boom and the connection of the adjacent boom are connected by a rotatable elbow. The specific structure of the cloth machine can be referred to figure 1 And the description in Example 1.

[0097] Combine below Figure 7 As shown, the intelligent distribution control system of the cross-boom concrete distributor is further introduced.

[0098] The intelligent cloth control system includes an intelligent terminal 21, a PLC controller 22, a driver one 23, a dr...

Embodiment 3

[0107] This embodiment provides a method for controlling smart cloth using the smart cloth control system in the second embodiment. The following is combined with the second embodiment and the appendix. Figure 7 The control method is further explained. The control method includes the following steps:

[0108] Step 1. Step 1. Store the target path of the distributor and concrete pouring information in the intelligent terminal. The distribution path includes several turning angle parameters of the slewing mechanism group, and the concrete pouring information includes the flow valve opening parameters;

[0109] Step 2: The intelligent terminal sends the turning angle parameters of the slewing mechanism and the flow valve opening parameters to the PLC controller;

[0110] Step 3. The PLC controller controls the driver 1 according to the received rotation angle parameters of the slewing mechanism, and brakes the slewing mechanism after turning into place; the PLC controller controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com