Pure countercurrent modular combined heat exchanger

A heat exchanger and modular technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problem of reducing the cost performance of flue heat exchangers, affecting the application of waste heat recovery technology, and heat transfer The problem of large attenuation of the heat exchange performance of the device can be solved, so as to reduce the energy consumption of the system, achieve good heat transfer effect, and realize the effect of flexible load adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

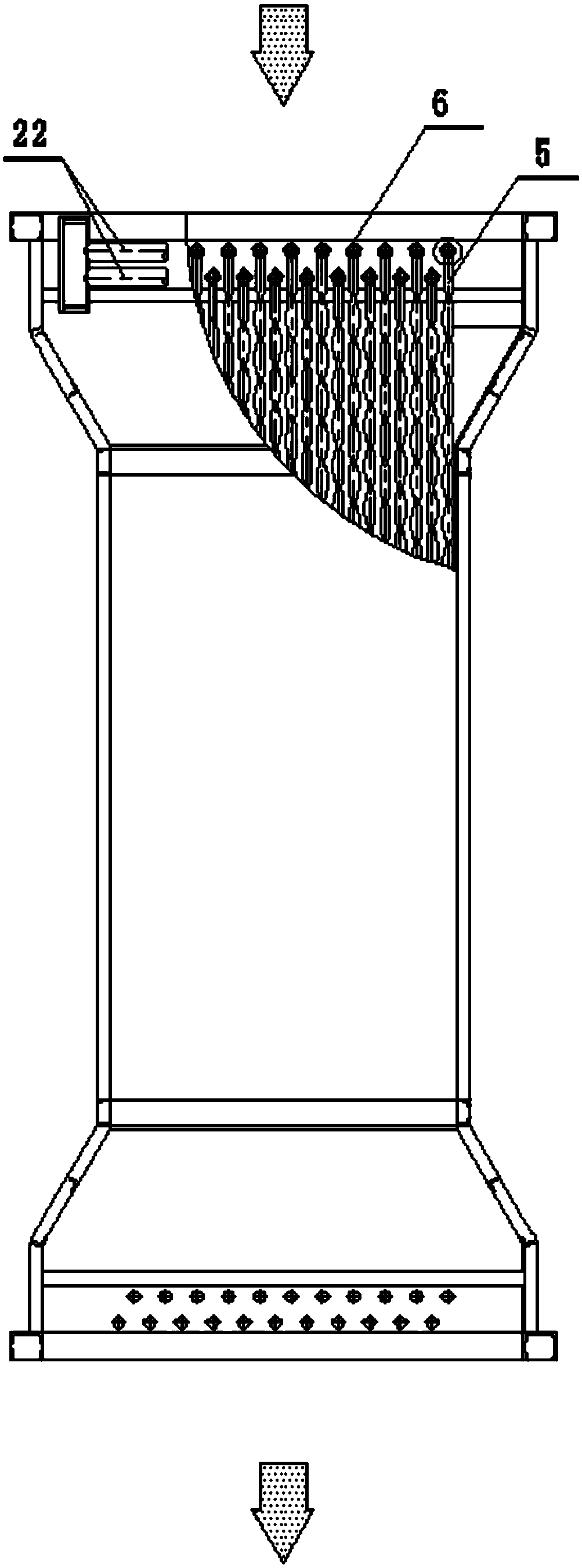

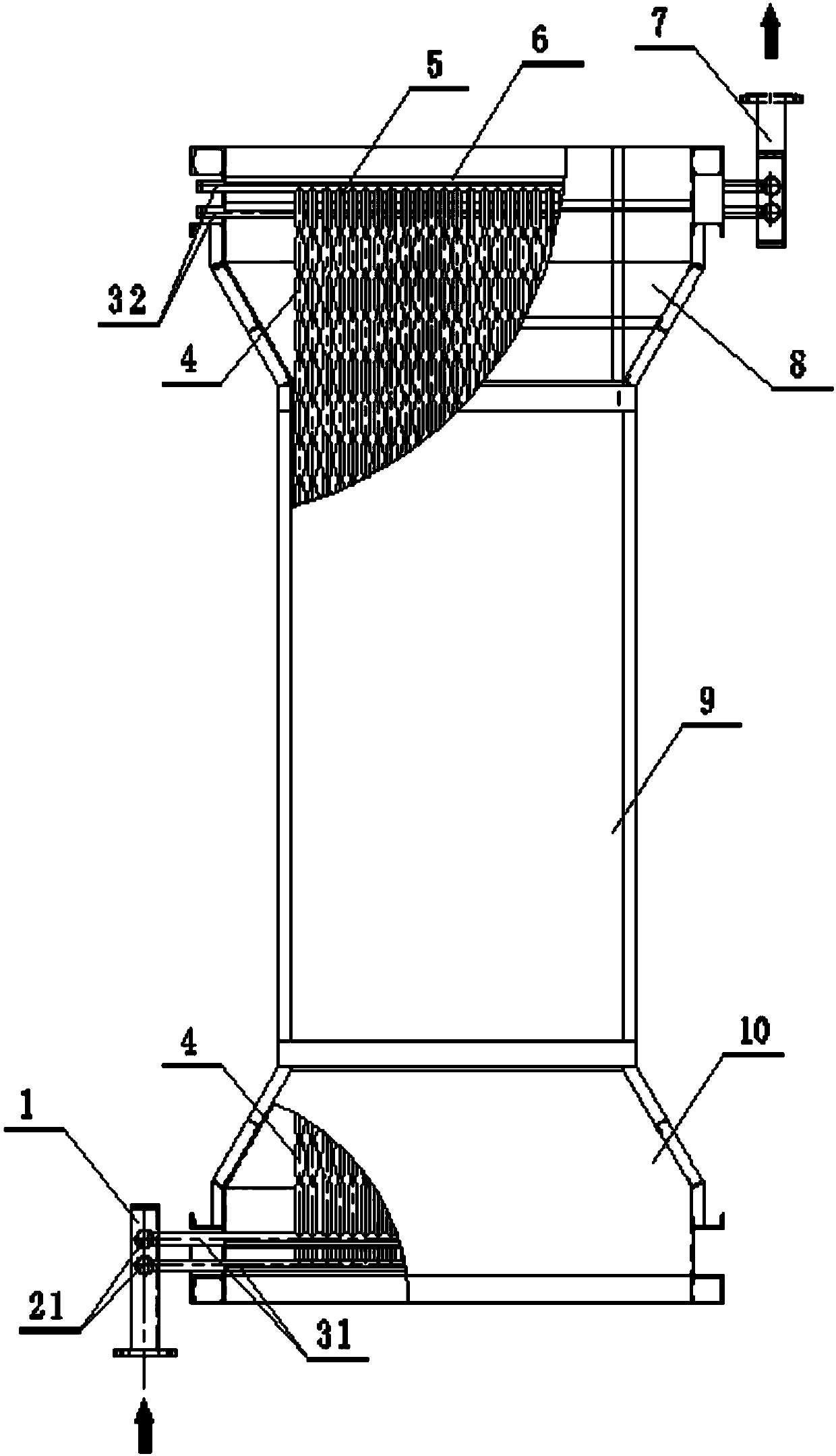

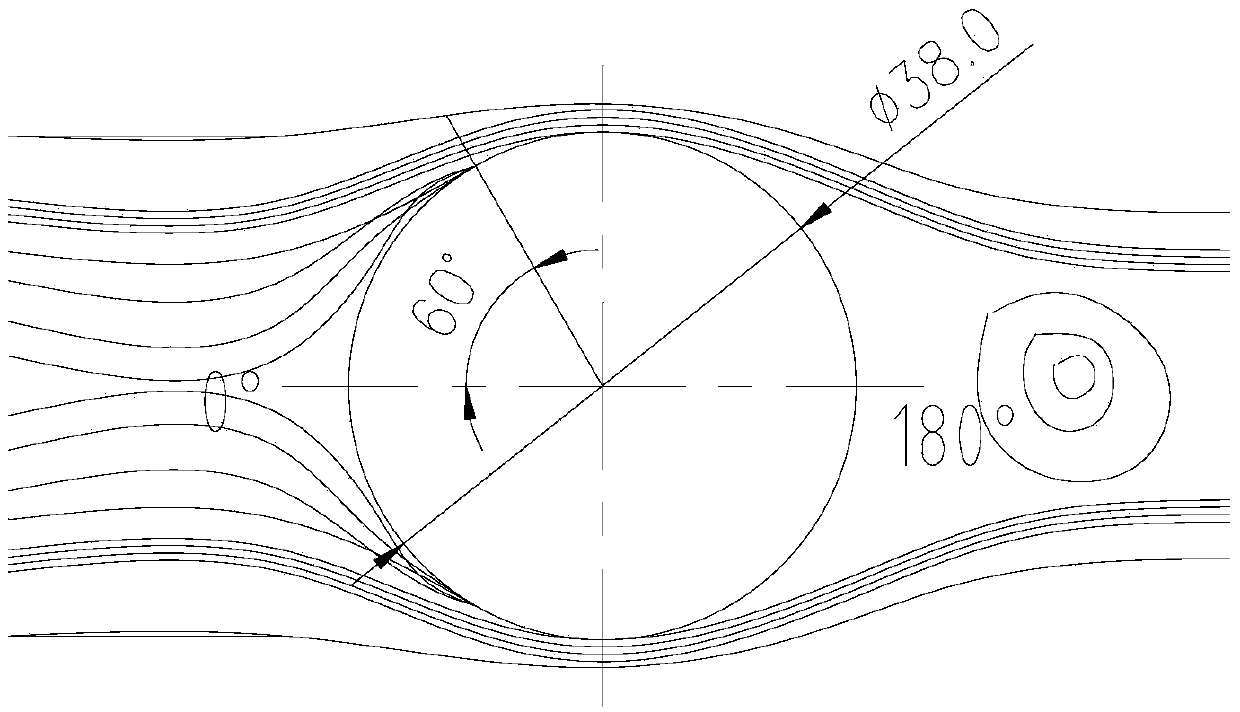

[0025] refer to figure 1 , figure 2 , Figure 4 to Figure 7 , which is a pure countercurrent modular combined heat exchanger. The heat exchanger adopts vertical or horizontal square flue pipe arrangement, which includes steam inlet main pipe 1, large header, small header, and several groups of combined arrangements. Heat exchange tube group 5, steam outlet main pipe 7, shrinkage inlet section cylinder 8, expansion outlet section cylinder 10 and steady flow straight section cylinder 9; heat exchange tube group 5 consists of multiple high specific surface heat exchange tube groups 5 The shrinkage inlet section cylinder body 8 and the expansion outlet section cylinder body 10 are respectively arranged at the two ends of the steady flow straight section cylinder body 9 to form a heat exchange cylinder, and the heat exchange tube group 5 is located in the heat exchange cylinder; the large header includes a large inlet The header 21 and the large outlet header 22, the small heade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com