Connector and optical fiber connecting assembly

A technology of connectors and elastic parts, applied in optical components, instruments, optics, etc., can solve problems such as difficult operation, and achieve the effects of convenient operation, saving operating space, and good error-proof operation measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

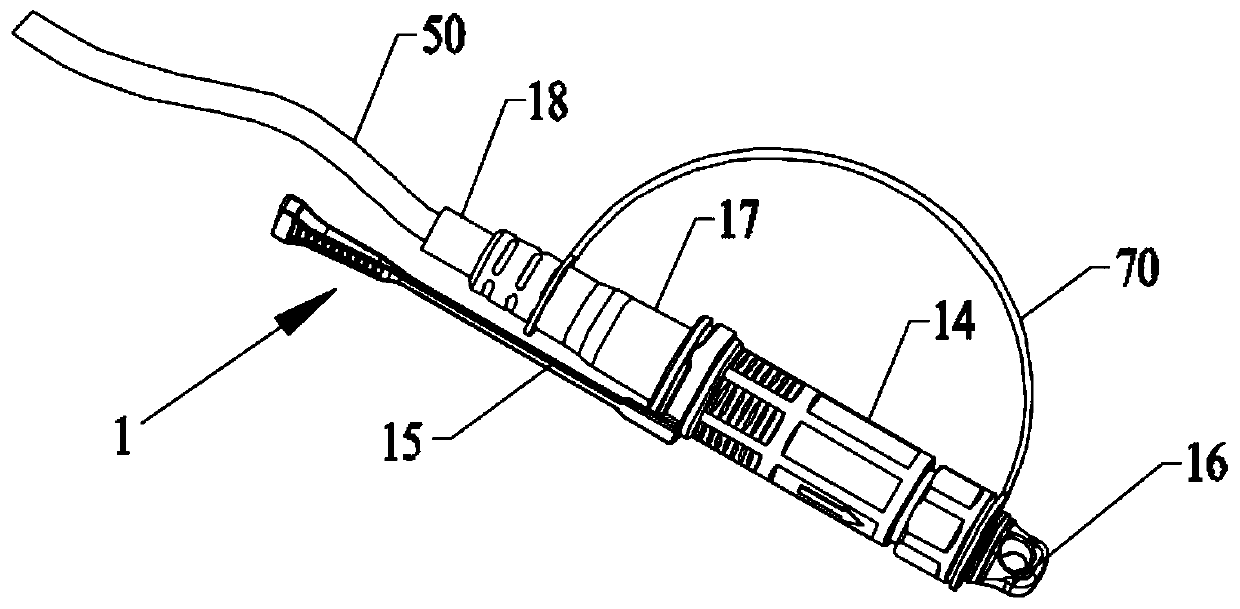

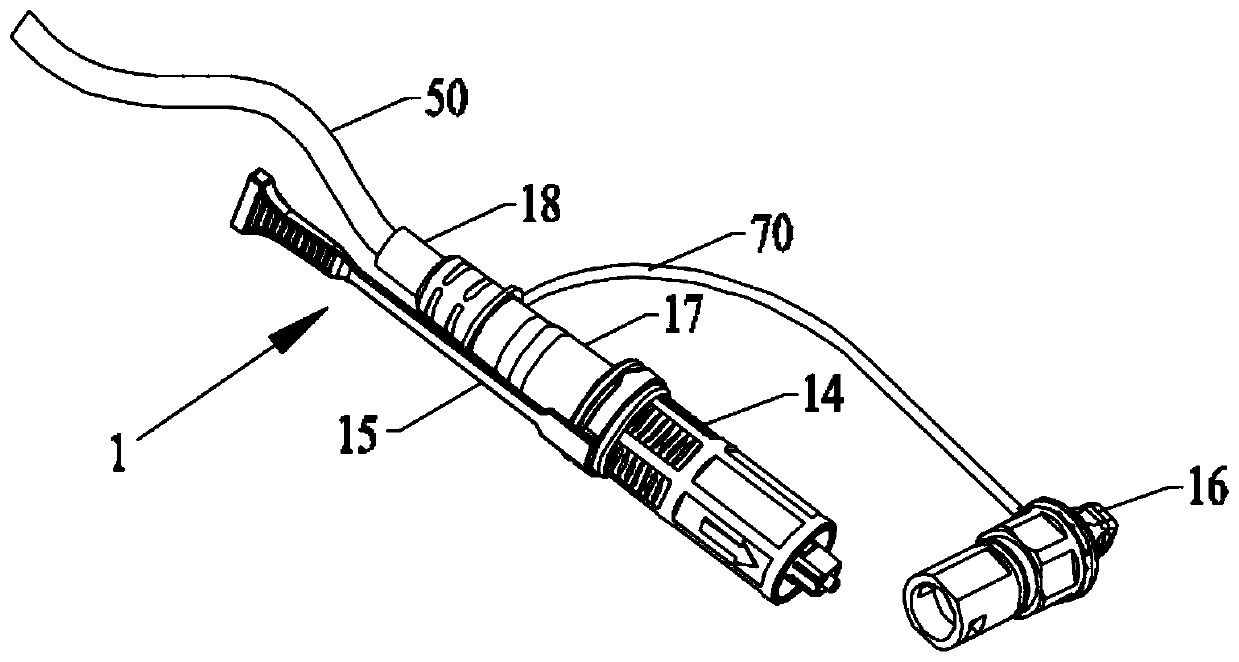

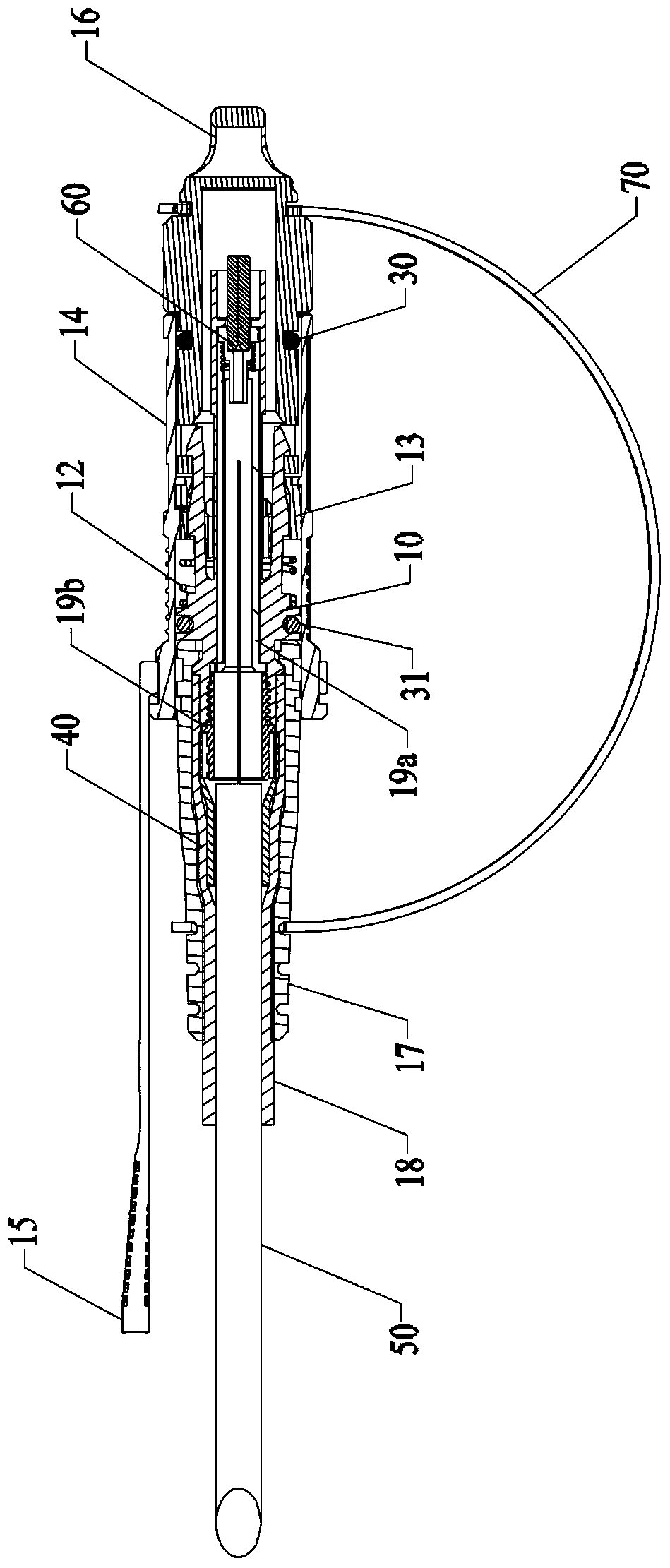

[0074] see Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a connector, which includes a connector body 10, a buckle assembly, an elastic member 12, an unlocking ring 13, a connector jacket 14, a drawstring 15, a connector cap 16, and a connector boot 17. Connector hot melt tube 18, connector front sleeve 19a, connector rear sleeve 19b, aluminum cup 40, connector optical cable 50, ferrule assembly 60 and connector connecting rope 70.

[0075] Wherein, the connector body 10 includes an insertion portion 101 , and a positioning buckle 102 is respectively provided on opposite sides of the insertion portion 101 . The insertion part 101 is mainly used for docking with a matching adapter.

[0076] At the other end of the connector body 10, the connector optical cable 50 is crimped and fixed by the aluminum cup 40, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com