Strip steel surface rapid quality discrimination and defect feature automatic extraction method

A quality screening and automatic extraction technology, applied in the field of computer vision, can solve problems such as difficult to effectively extract real defects, false edges, light interference, etc., to meet the requirements of real-time online defect detection, high accuracy, and low hardware performance requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for rapid quality screening and defect feature automatic extraction of strip steel surface, comprising the following steps:

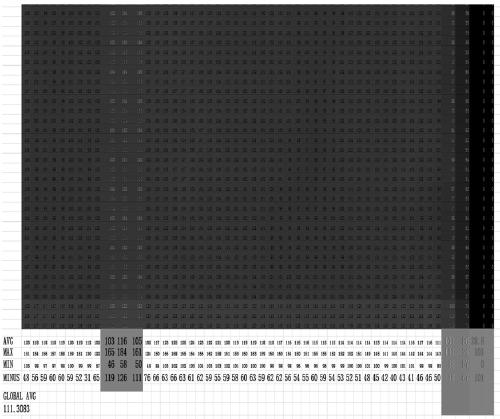

[0042] (1) Gray-scale projection is performed on the collected strip steel surface image in a column-down and row-to-right manner to obtain a gray-scale matrix image;

[0043] (2) Analyze the grayscale matrix image obtained in step (1) to find the maximum value R of the grayscale projection value of each row in the grayscale matrix image Max , minimum R Min and the maximum value C of each column of grayscale projection values Max , minimum value C Min , calculate the average value R of each row of grayscale projection Avg , each column of gray projection mean C Avg And the global gray mean of the entire gray matrix image Global Avg , and then judge the defect area, non-defect area, boundary pseudo-defect area, transition area between the strip boundary and the background in the strip surface image according to the mean value of the ...

Embodiment 2

[0058] Example 2: Validation experiment of the present invention's strip steel surface rapid quality screening and defect feature automatic extraction method

[0059] 1. Detect the strip steel image with longitudinal inclusion defects on the surface

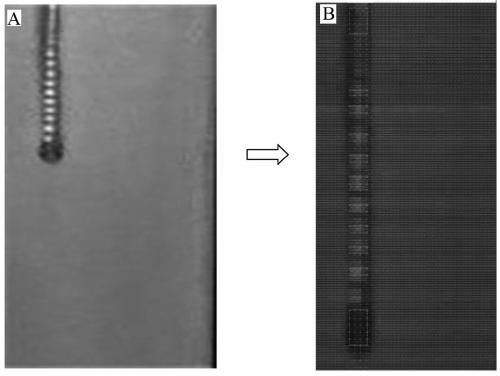

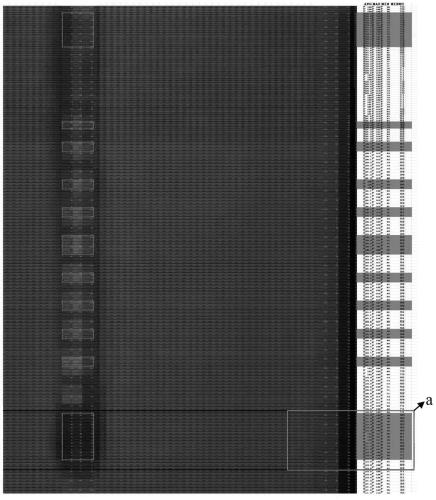

[0060] Adopt the method for the embodiment of the present invention 1 to detect the strip steel image that the surface has longitudinal grain defect, wherein the strip steel surface original image that gathers is as follows figure 1 As shown in A, by figure 1 In A, it can be seen that there are longitudinal grain defects in the strip steel image to be detected, the background area of the strip steel shooting, and the transition area between the strip steel boundary and the background. Test results such as figure 1 As shown in B (B is a partial image of the detection result), the defect area in Figure B has been framed by a box, that is, the area framed by the box is the detected defect characteristic ROI area, and Figure B ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com