Electric vehicle and battery module thereof

A technology for electric vehicles and battery modules, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of low connection strength of battery modules, achieve strong bonding ability, ensure working stability, and fill more space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will now be described in conjunction with the accompanying drawings.

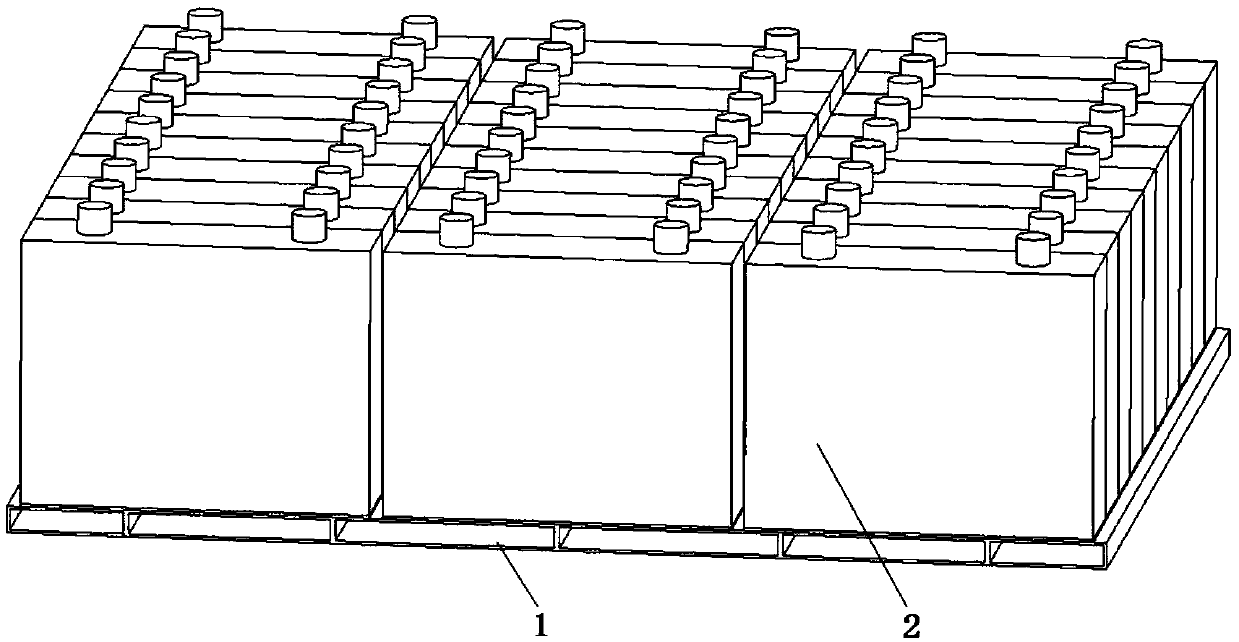

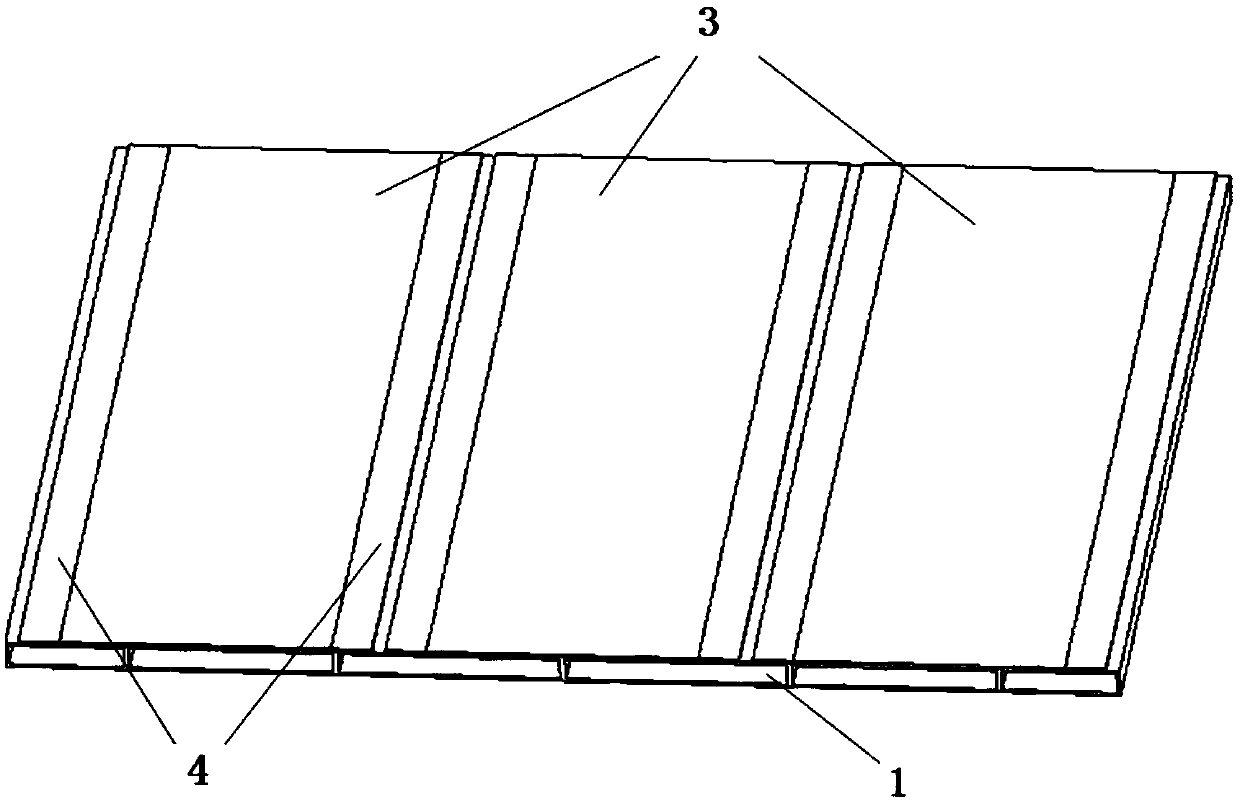

[0028] An electric vehicle includes a frame forming a main body of the electric vehicle, on which a battery module as a power source of the electric vehicle is arranged. Such as figure 1 As shown, the battery module includes a liquid cooling plate 1 and battery cells 2 arranged on the liquid cooling plate 1. The battery cells 2 will generate heat when charging or discharging, and a cooling medium channel is provided in the liquid cooling plate 1. When cooling the medium, the battery cell 2 will be cooled and dissipated, and the battery cell 2 will remain in a stable working state. In order to ensure the connection relationship between the battery cell 2 and the liquid cold plate 1, a structural adhesive 4 is provided between the battery cell 2 and the liquid cold plate 1. The function of the structural adhesive 4 is to stabilize the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com