Power device for hydraulic engineering

A technology for power devices and water conservancy projects, applied to watering devices, machines/engines, pumps, etc., can solve problems such as reducing water hammer pressure and reducing water pumping efficiency of water hammer pumps, so as to increase water hammer pressure and improve pump efficiency. Water efficiency, the effect of improving water extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

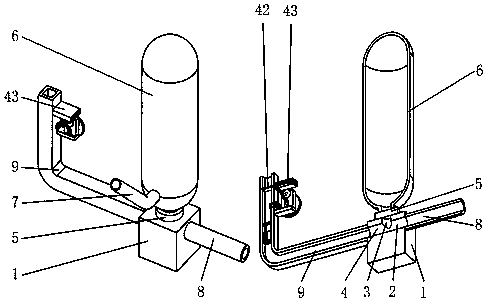

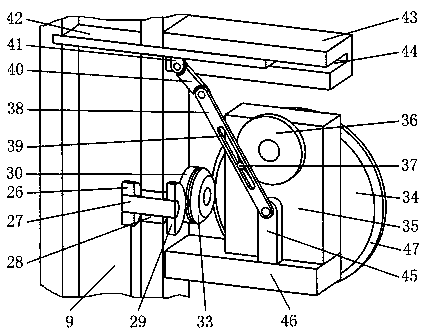

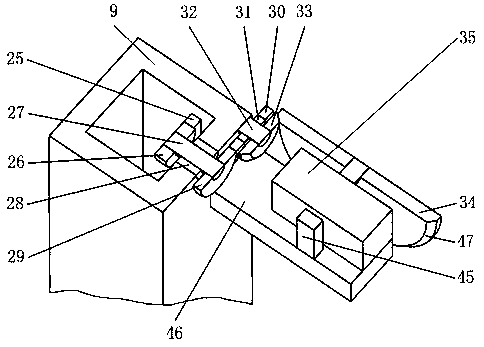

[0031] Such as figure 1 , 3 , 8, it includes tee seat 1, one-way valve 5, high-pressure tank 6, outlet pipe 7, water inlet pipe 8, power pipe 9, power block 12, shaft A27, dynamic sealing ring 28, shaft B32, bevel gear 33, flywheel 34, speed reducer 35, crank wheel 36, dial pin 37, fork 38, connecting rod 40, baffle plate 42, wherein as figure 1 As shown, the high-pressure tank 6 is installed at the outlet A3 of the three-way seat 1 through the one-way valve 5, and the three-way seat 1 is fixed on the ground; the side wall of the high-pressure tank 6 is equipped with an outlet pipe 7 near the one-way valve 5; the three-way The inlet 2 of the seat 1 is connected with the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com