Cocoon picking machine and cocoon picking method for factory farming

A kind of industrialization and cocoon picking technology, which is applied in animal husbandry and other fields, can solve the problems of low cocoon output, large failures, and many cocoons, and achieve the effect of improving the effect of cocoons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

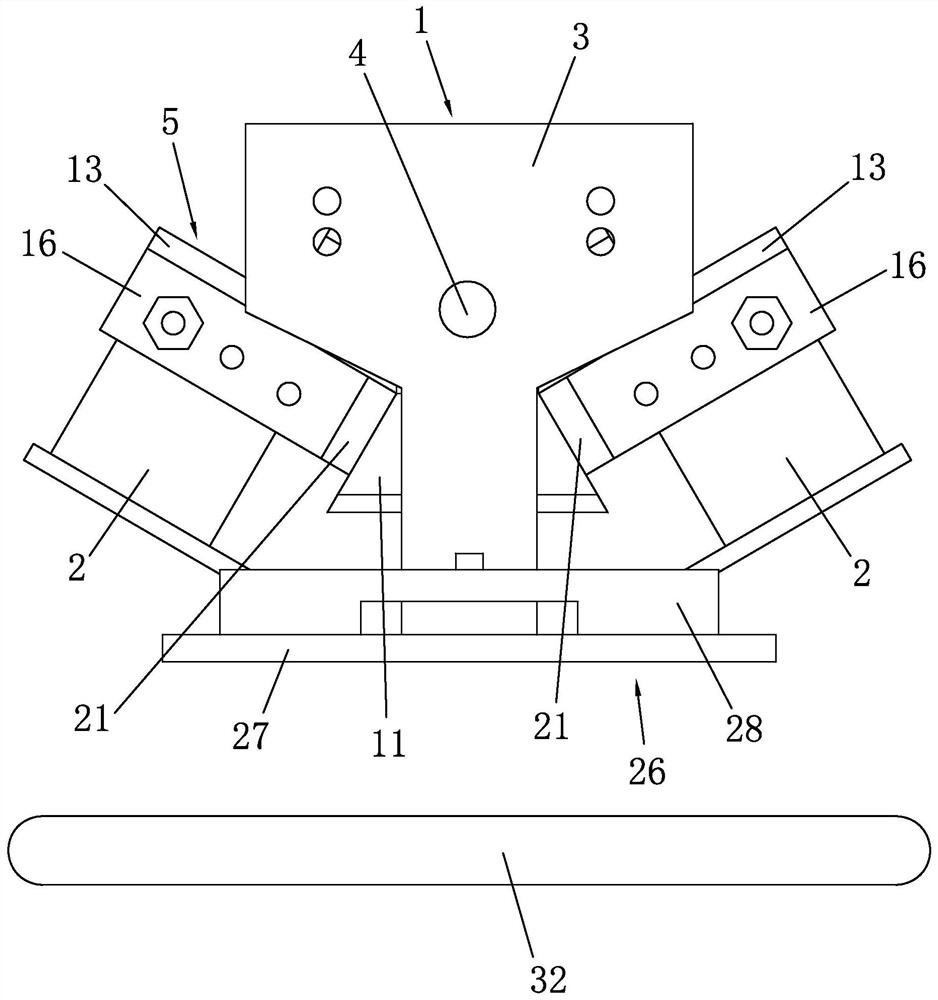

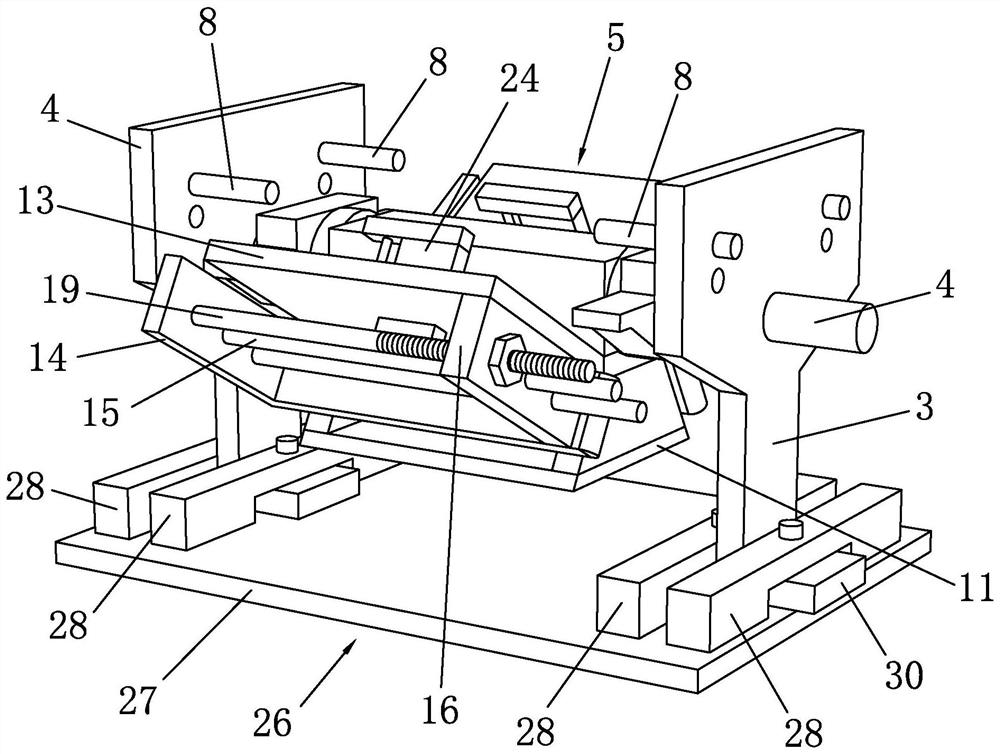

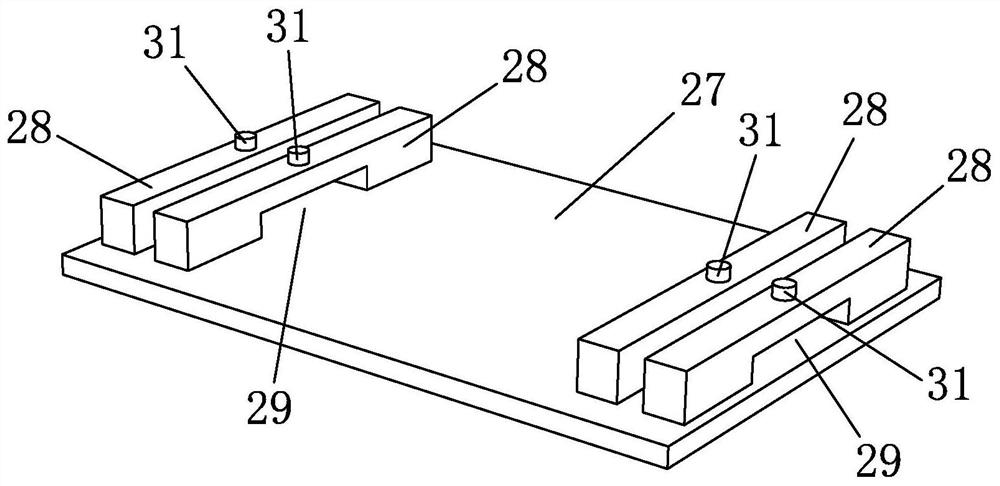

[0043] Such as Figure 1 to Figure 7 As shown, it is a cocoon picking machine for industrial farming according to the present invention, which includes a swing mechanism 1, a brush mechanism 2 and a conveyor belt 32. The swing mechanism 1 is used to install cocoon cages and perform reciprocating swing motions. The hairbrush mechanism 2 is installed under the cocoon cage, and the hairbrush mechanism 2 brushes off the silkworm cocoons on the cocoon cage. The conveyer belt 32 is arranged below the swing mechanism 1, and the conveyer belt 32 carries out concentrated conveyance to the brushed cocoons. The invention enables the cocoon cage to perform reciprocating swinging motion along with the swing mechanism, and the brush mechanism performs reciprocating cocoon picking work on the reciprocating swinging cocoon cage, so that less silkworm cocoons remain in the cocoon cage and the effect of silkworm cocoons is improved.

[0044] The swing mechanism 1 includes a mounting bracket 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com