Stainless steel micro-pore plate cleaning system and cleaning method thereof

A technology for cleaning systems and microplates, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as large workload, low cleaning efficiency, and poor repeatability, and achieve low workload , The effect of high cleaning efficiency and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

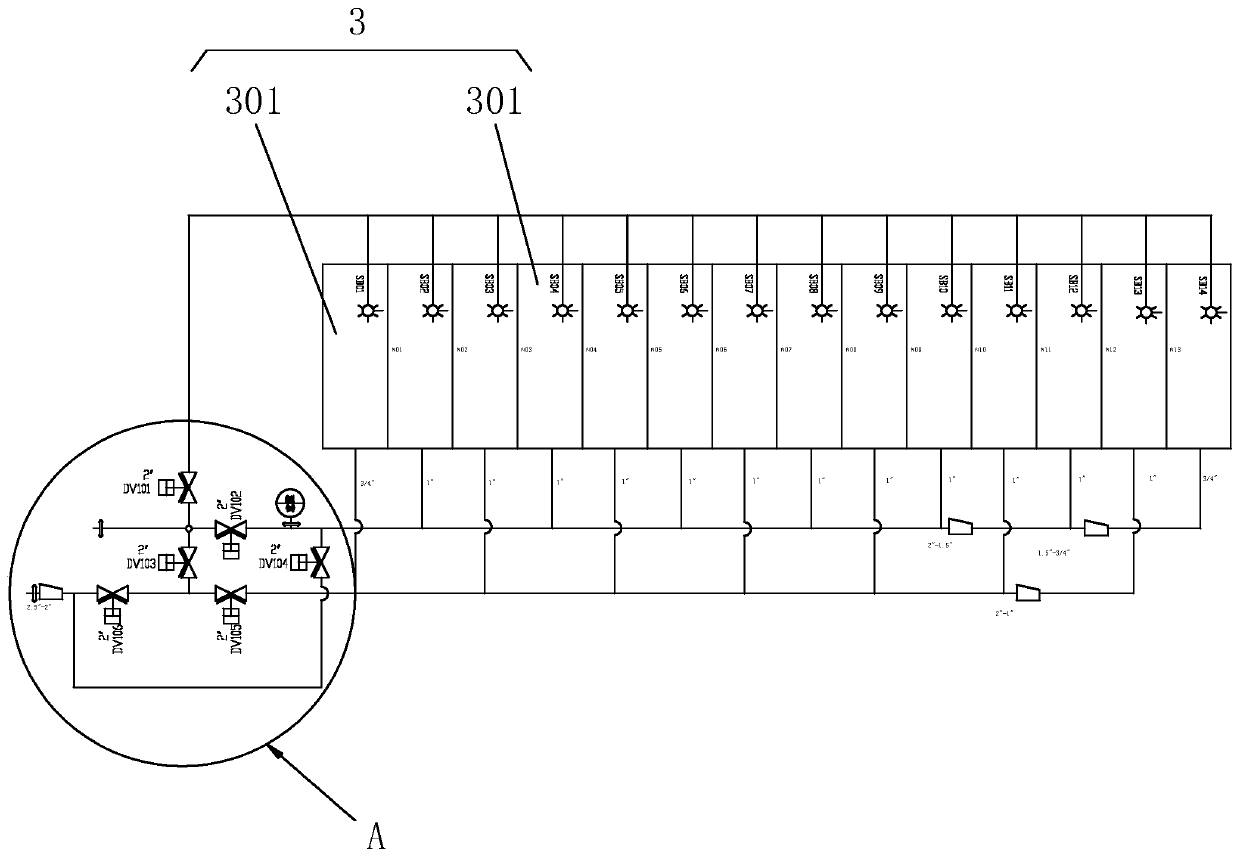

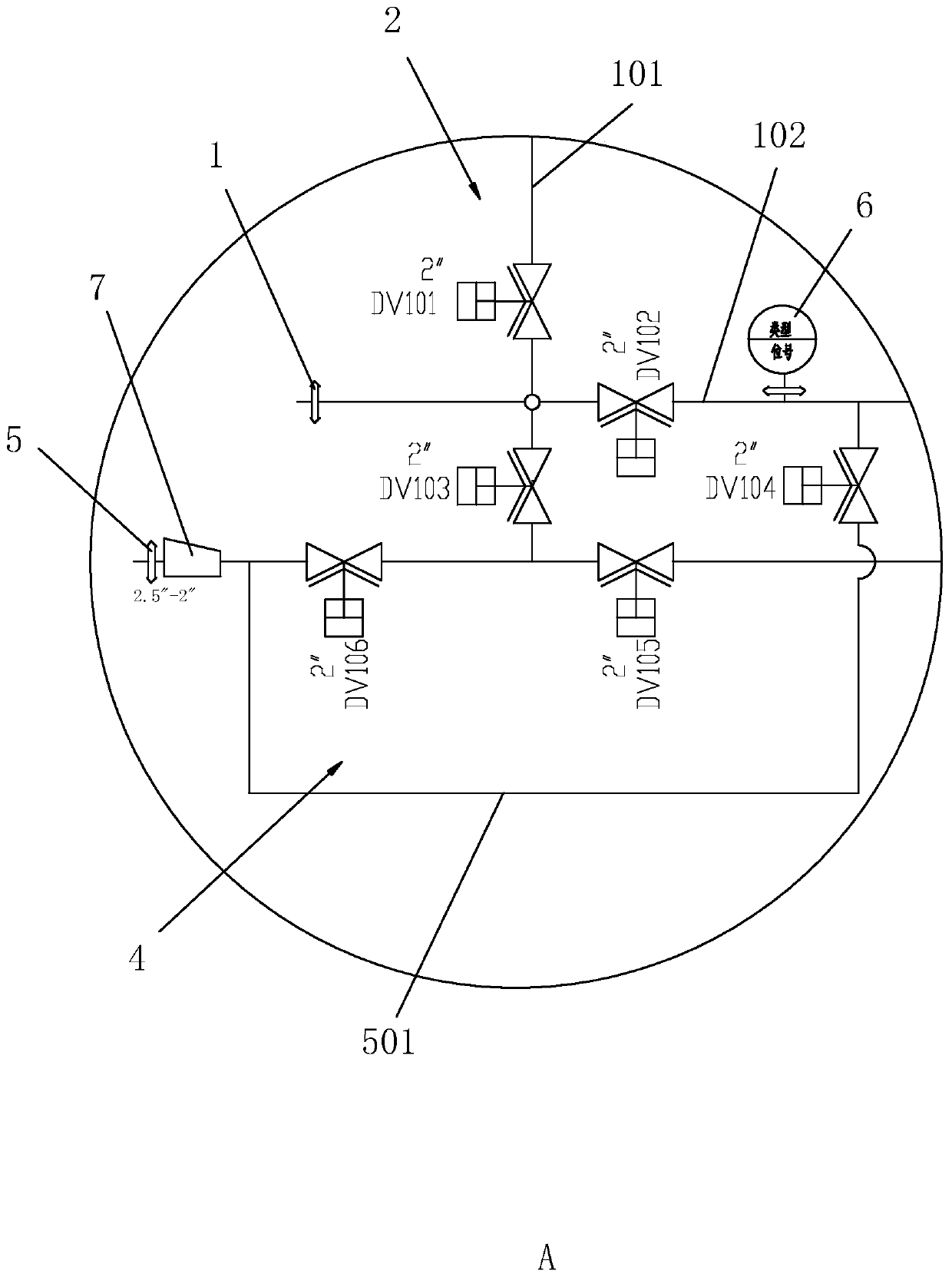

[0046] A stainless steel microplate cleaning system, such as figure 1 and figure 2 As shown, it includes a liquid supply pipeline 1 , a liquid supply valve group 2 , a cleaning ball group 3 , a liquid return valve group 4 and a liquid return pipeline 5 connected in sequence. The liquid supply pipeline 1 and the liquid return pipeline 5 are used to provide cleaning liquid, and the liquid supply valve group 2 and the liquid return valve group 4 are used to control the flow direction of the cleaning liquid together.

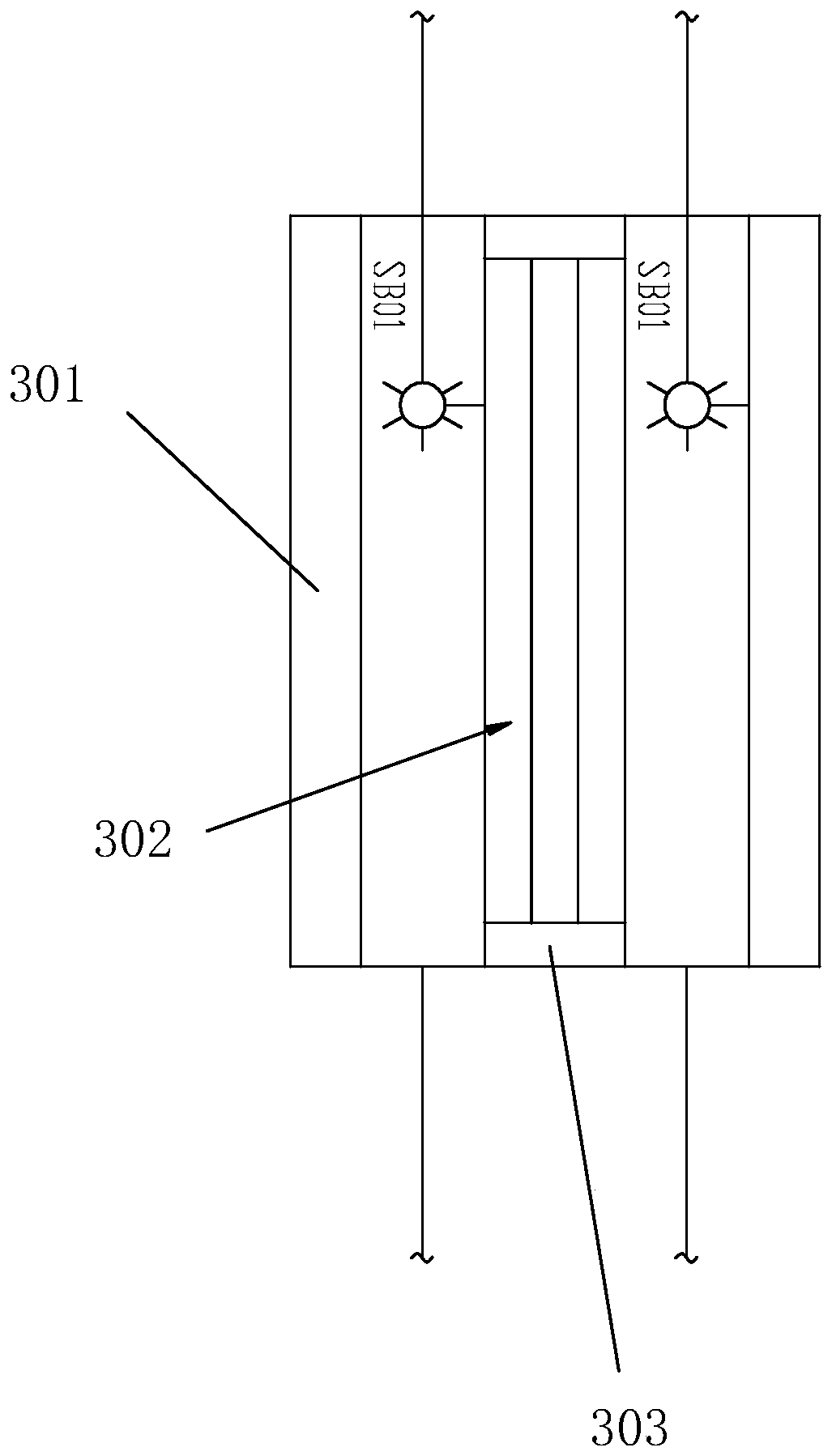

[0047] Such as image 3 As shown, the cleaning ball group 3 includes a plurality of parallel cleaning splints 301, and the cleaning splints 301 clamp the stainless steel microporous plate. The microporous cleaning channel, the cleaning channel is connected to the liquid supply valve group 2 from one side of the stainless steel microporous plate and extends to the other side of the stainless steel microporous plate and connected to the liquid return valve group 4 ...

Embodiment 2

[0053] A stainless steel microporous plate cleaning method, based on the above-mentioned stainless steel microporous plate cleaning system, comprises the following steps:

[0054] Such as figure 1 As shown, S1: Open valve DV101, close valve DV102, valve DV103 to supply cleaning liquid to cleaning ball group 3, pre-wash the surface of stainless steel micro-orifice plate, and open valve DV104, valve DV105, valve DV106 at the same time to return liquid. Among them, the whole machine pressure of the stainless steel microporous plate cleaning system is 4 kg, and the design of the whole machine pressure as 4 kg can make the system achieve the best cleaning energy efficiency ratio, so that both the cleaning effect and the cleaning energy consumption can be achieved.

[0055] Such as figure 2 As shown, S2: open valve DV102, close valve DV101, valve DV103, and valve DV104, supply liquid to odd chambers 302, perform positive washing on the microporous plate, and open valve DV105, DV10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap