Out-of-roundness control method for short-stress-path rolling mill

A technology with dimensional accuracy and short stress line, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of three-sided folding and edges and corners of finished products, difficult adjustment, large investment in rolling mills, etc., to eliminate the finished product shaft. wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for controlling the out-of-roundness dimensional accuracy of a short-stress-line rolling mill, comprising the following steps: 1), designing a rolling program in which the size of the K3 rolled piece is close to that of the finished product,

[0016]

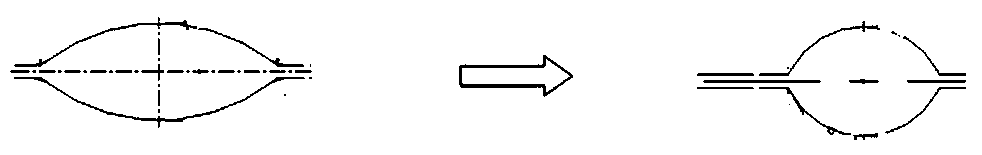

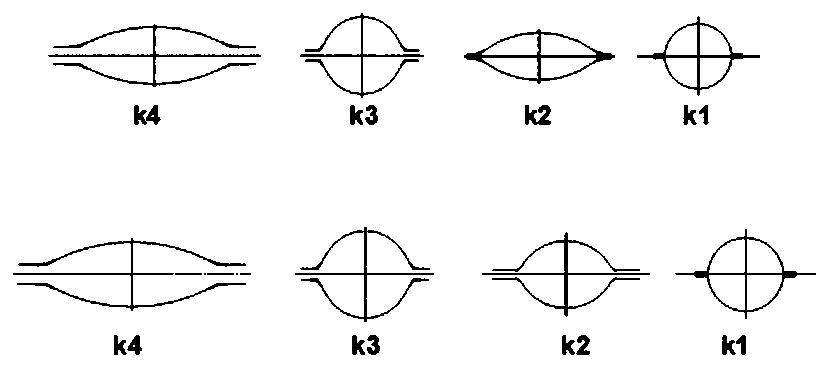

[0017] 2) if figure 1 , figure 2 As shown, design a true circle K2 hole pattern, and use the finished circle-round hole pattern to measure the circle; figure 2 The pass pattern in the middle and upper row is the pass pattern technology adopted in the prior art. figure 2 The pass pattern in the middle and lower rows is the pass pattern process adopted by the present invention, that is, the four pass patterns from K4 to K1 adopt the ellipse-circle-circle-circle true circle pass return process;

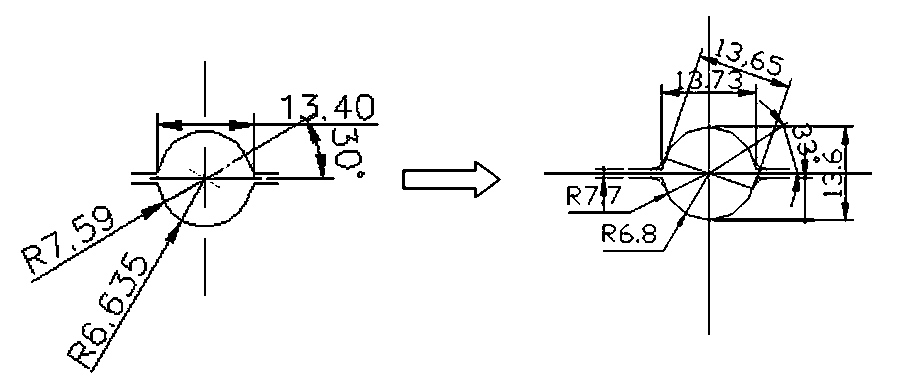

[0018] 3) Modify the K1 finished pass, such as image 3 As shown, ensure that the size of the two shoulders of the pass is 0.5mm larger than the bottom of the pass;

[0019] 4) Modify the K1 guide wheel, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com