Steel plate net punching and shearing machine

A technology of punching and shearing machine and expanded metal mesh, which is applied to shearing device, shearing machine equipment, feeding device, etc., can solve the problems of complex transmission, and achieve the effect of flexible use, simple structure and equipment cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

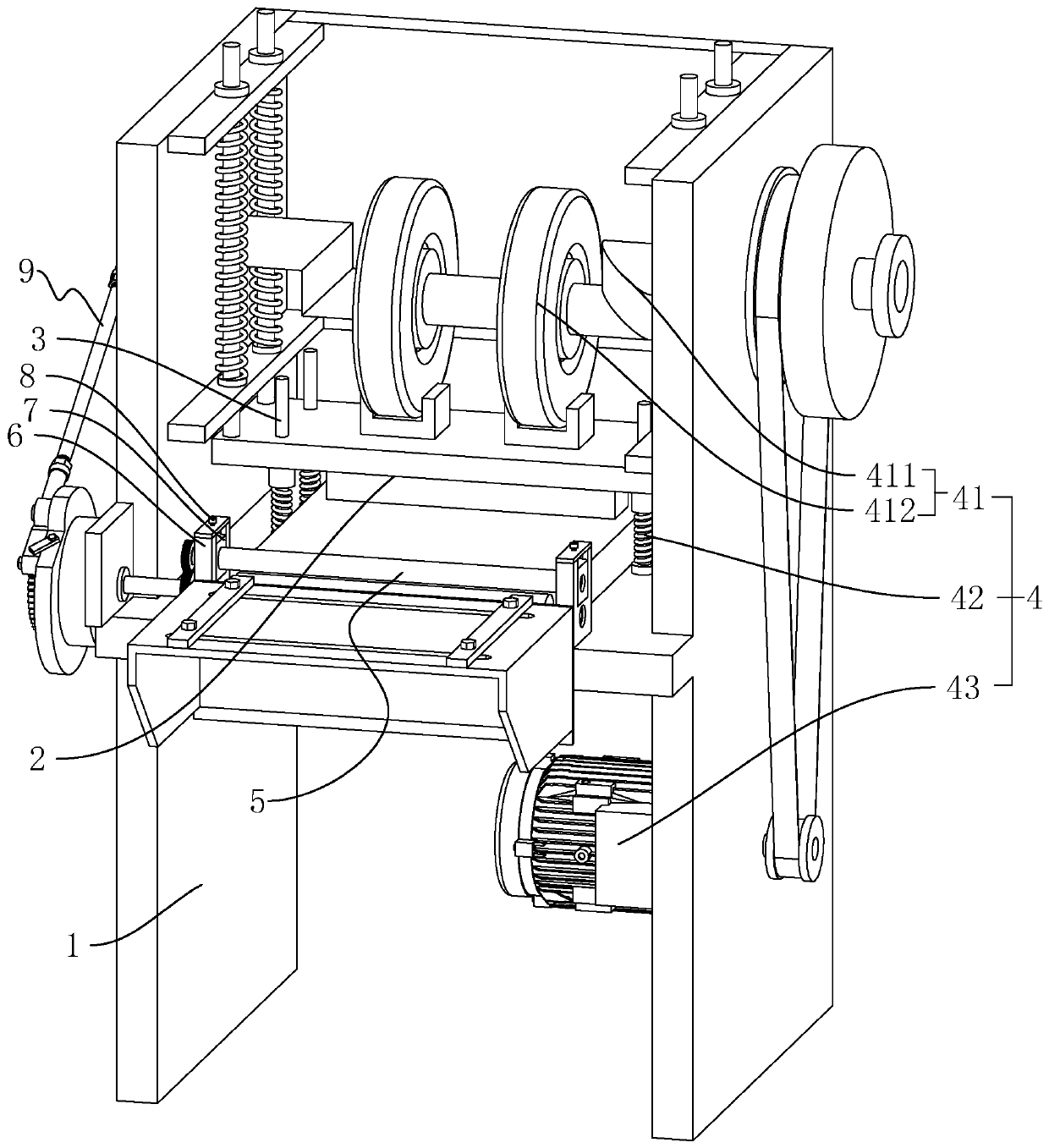

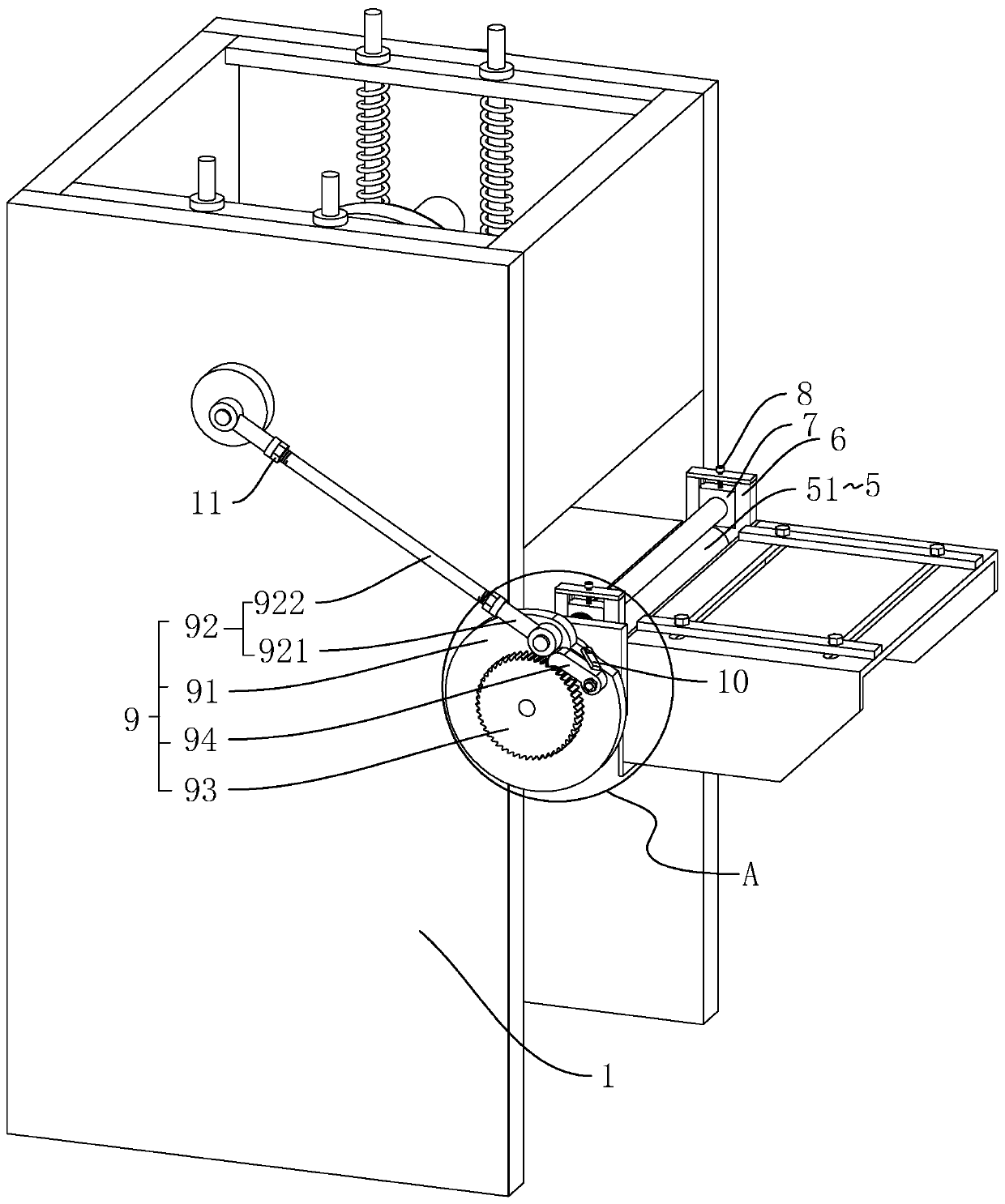

[0039] An expanded metal punching and shearing machine, such as figure 1As shown, it includes a frame 1 on which an upper knife rest 2 slides vertically, and the lower end surface of the upper knife rest 2 is correspondingly equipped with a blade for punching and shearing. Also be vertically fixed with some guide shafts 3 on the frame 1, move up and down by guide shaft 3 guiding upper knife rest 2. The frame 1 is also provided with a driving device 4 , the driving device 4 includes a cam mechanism 41 rotatably connected to the frame 1 , a return spring 42 arranged on the frame 1 , and a driving motor 43 arranged on the frame 1 . The cam mechanism 41 is located above the upper knife rest 2, and the return spring 42 is sleeved on the guide shaft 3 and pressed against the lower end surface of the upper knife rest 2. The elastic force of the return spring 42 makes the return spring 42 press against the upper knife rest 2 so that the upper The upper end surface of the knife rest 2...

Embodiment 2

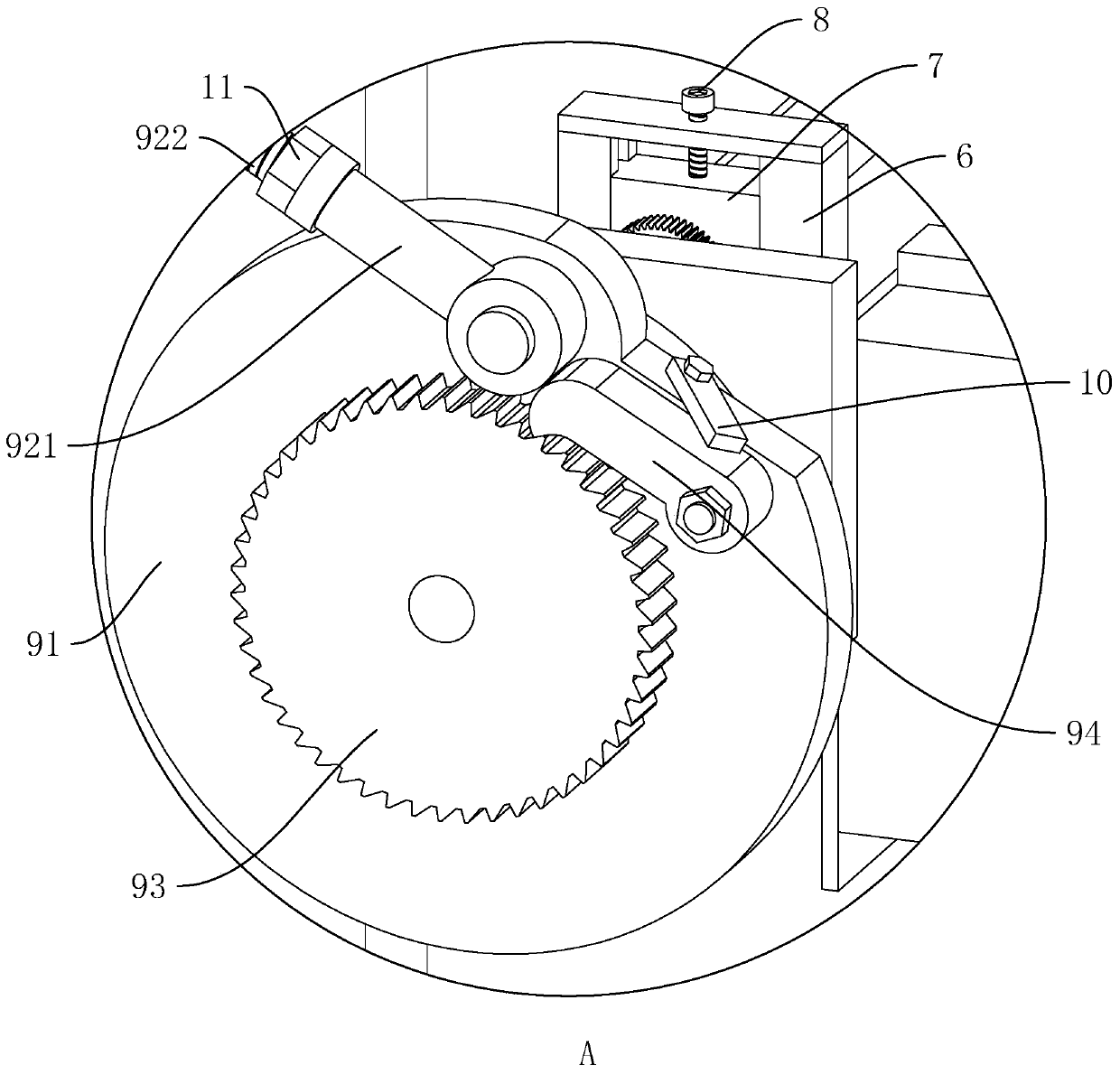

[0048] An expanded metal punching and shearing machine, such as Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is that the end surface of the cam mechanism 41 connected with the hinge rod 92 is also provided with an adjustment assembly 12 . The adjustment assembly 12 includes an adjustment block 121 that is slidably connected to the cam mechanism 41 in a direction perpendicular to the rotation axis of the cam mechanism 41, an adjustment screw 122 that is threaded on the adjustment block 121 and is rotatably connected with the cam mechanism 41, and the adjustment block 121 is also A hinged column 13 is fixed, and the hinged rod 92 is hinged with the cam mechanism 41 by being hinged with the hinged column 13 . The guide rail 14 is correspondingly fixed on the cam mechanism 41 , and the adjustment block 121 is provided with a chute 15 for the guide rail 14 to slide. The adjustment block 121 slides through the cooperation of the guide rail 14 and the chute 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com