Cutting equipment capable of clamping pipes with different lengths

A technology for cutting equipment and pipe fittings, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine devices, etc. It can solve the problems of inability to clamp and fix pipe fittings of different sizes, unstable clamping and fixing, and difficult clamping of pipe fittings. Achieve the effects of easy promotion and use, simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

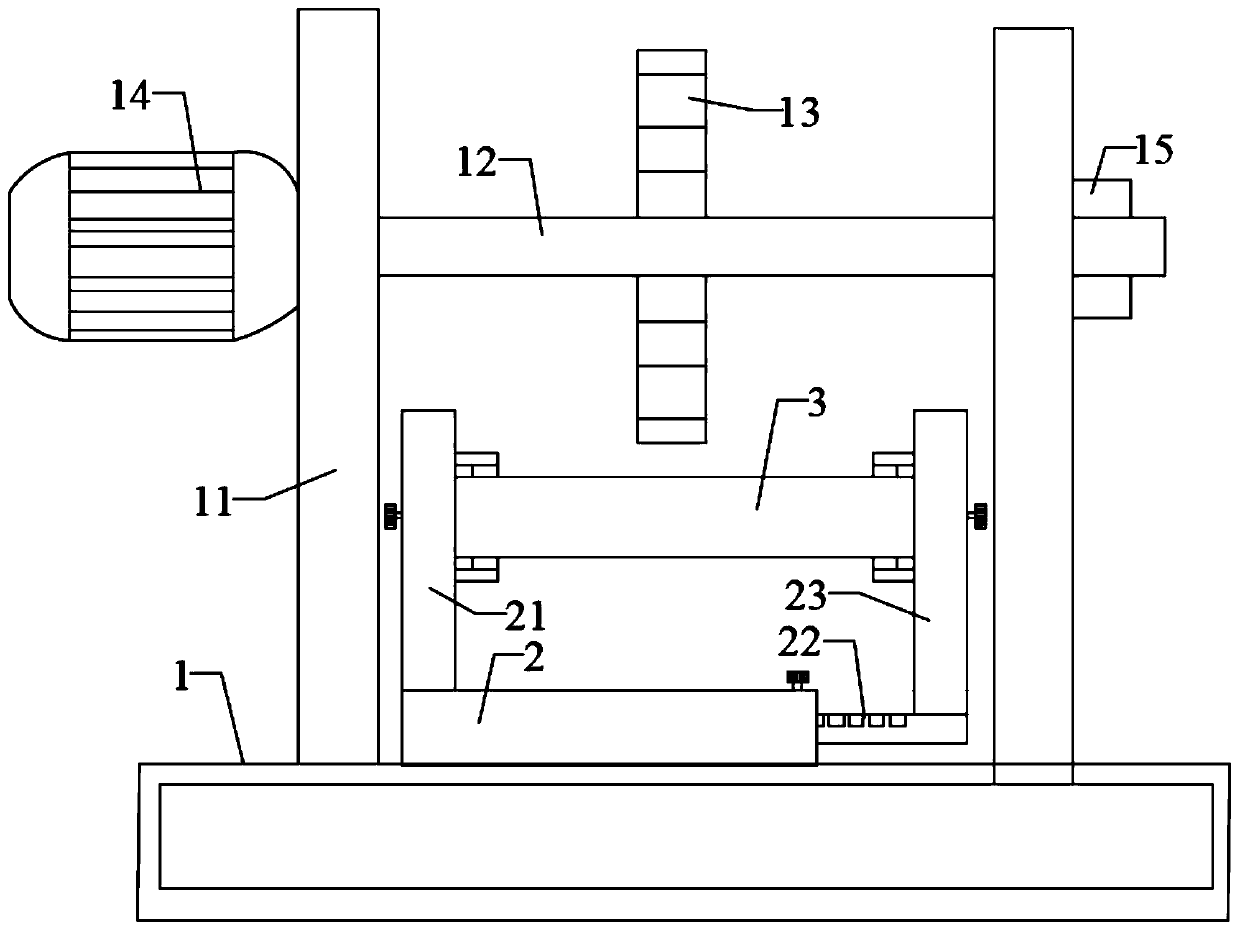

[0034] A cutting device capable of clamping pipes of different lengths, comprising a base 1 and a clamping device;

[0035] Support plates 11 are fixedly installed on both sides of the top of the base 1 , and a rotating shaft 12 runs through between the two supporting plates 11 , and a cutting wheel 13 is fixedly installed in the middle of the rotating shaft 12 , and the rotating shaft 12 One end passes through the left support plate 11 and extends to the outside of the left support plate 11 to be fixedly connected with the output shaft of the drive motor 14, and the other end passes through the right support plate 11 and the fixed block 15 in turn and extends to the right side of the fixed block 15 ;

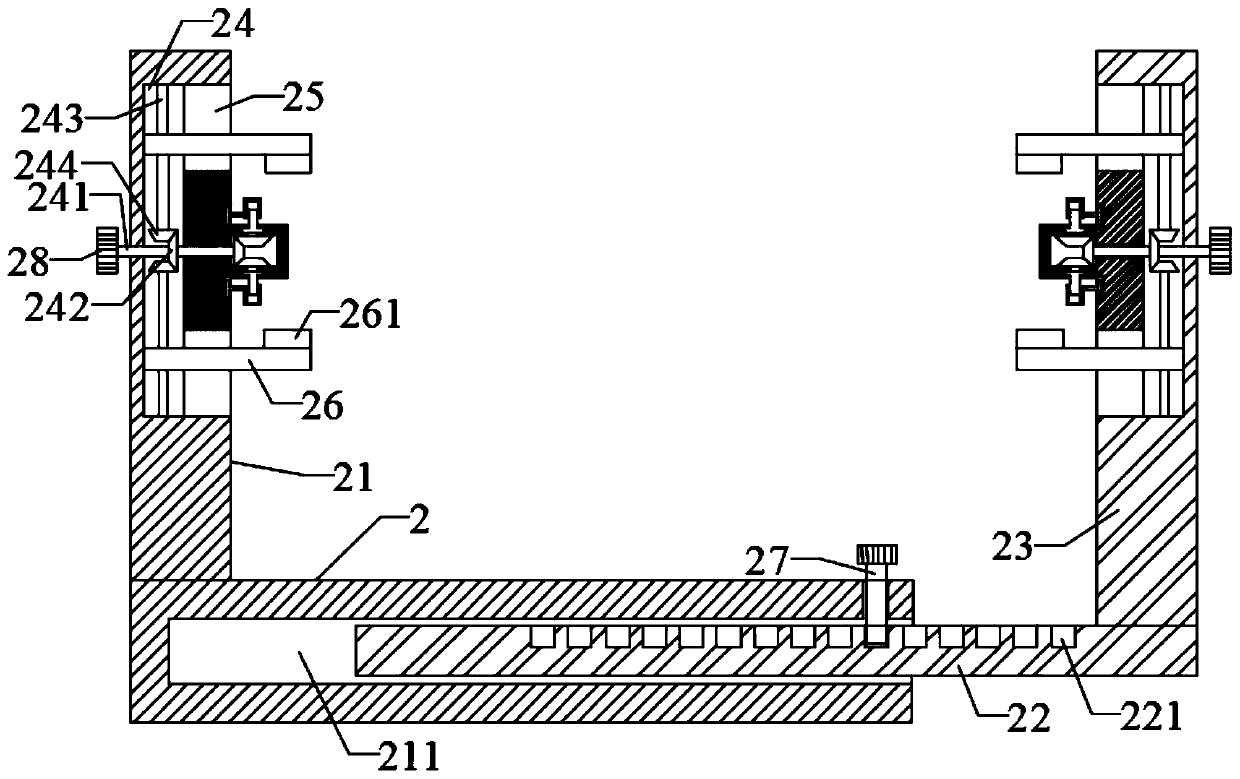

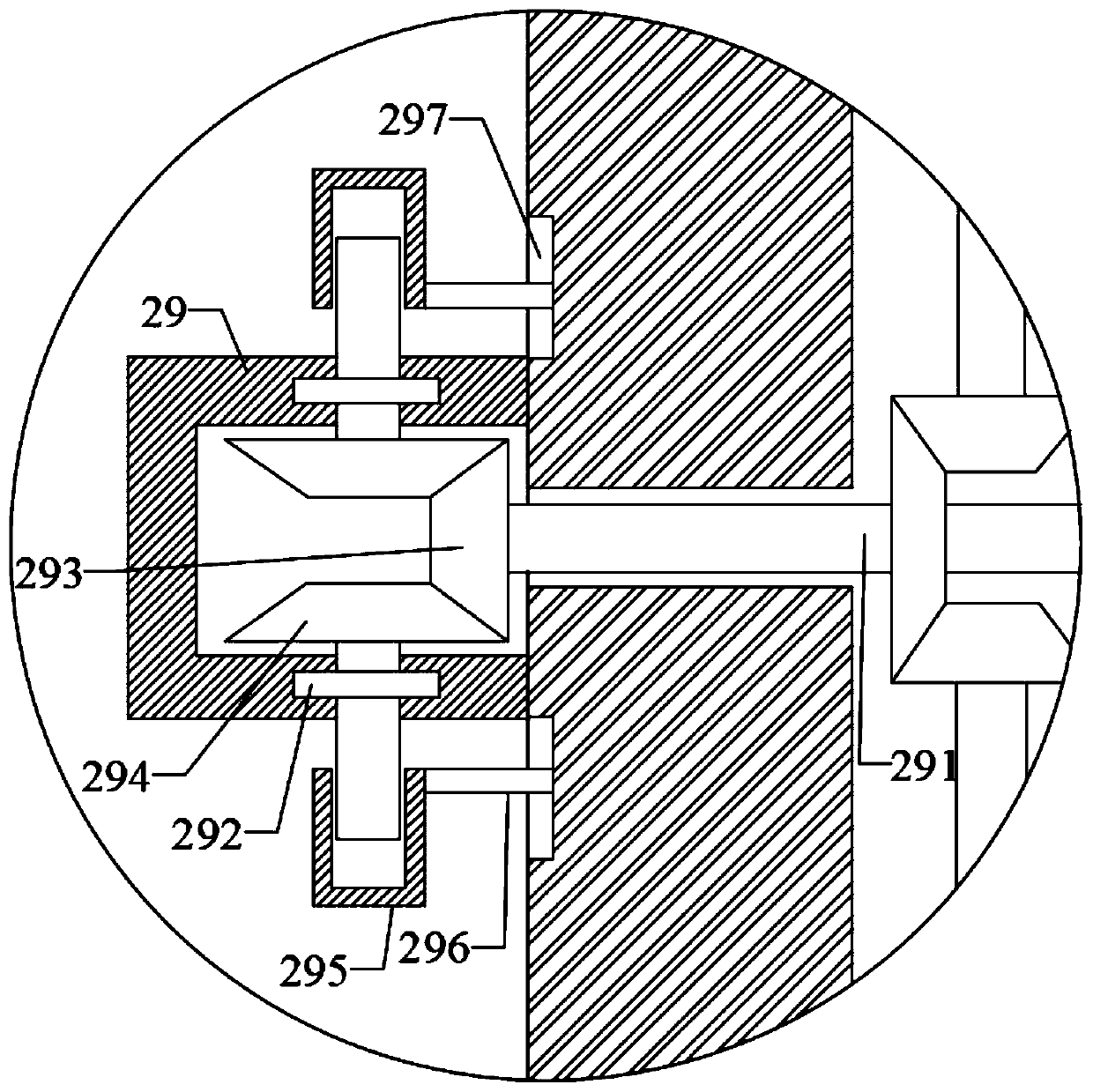

[0036] The clamping device includes a support base 2, the support base 2 is arranged on the top surface of the base 1, a first bracket 21 is fixedly connected to the side wall of the upper end on one side of the support base 2, and the support base 2 is far away from the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com