Long-life backfill stirring friction welding tool

A friction stir welding, long-life technology, applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the problems of reducing the service life of welding tools, wear of shaft shoulders and bushings, cold cracks of welds, etc., to reduce the vertical Upsetting force, high heating efficiency, and the effect of reducing cold cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

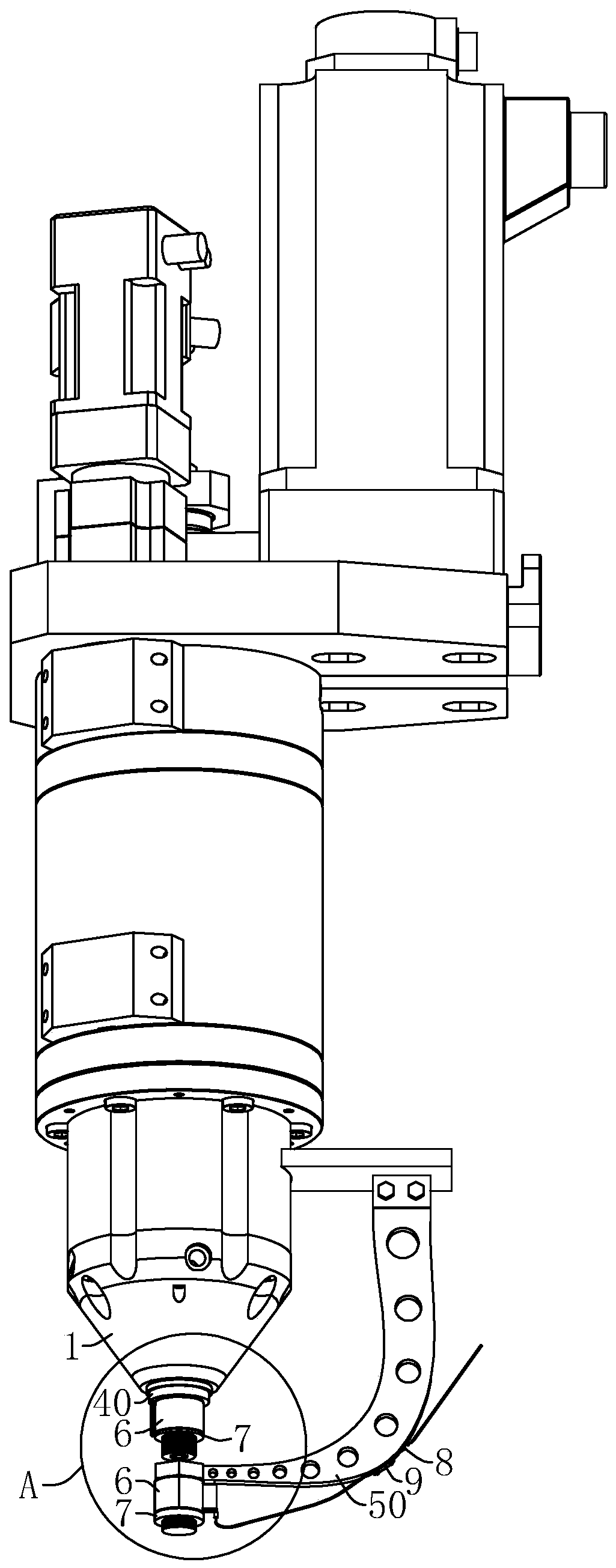

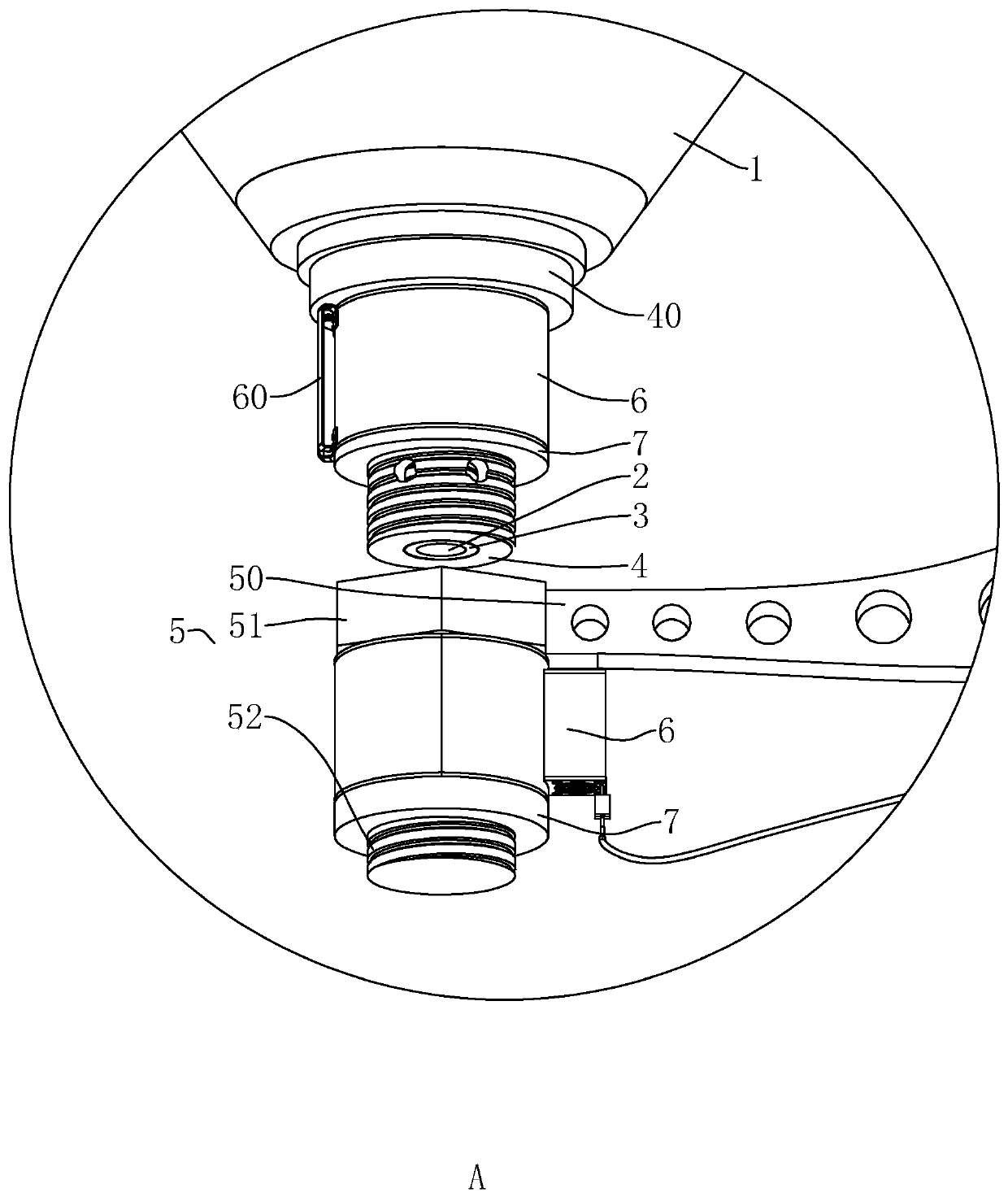

[0033] refer to figure 1 , figure 2 , a long-life backfill friction stir welding tool, including a machine head 1, a stirring pin 2, a shaft shoulder 3, a bushing 4, and a heating collar 6; the stirring pin 2, the shaft shoulder 3, and the bushing 4 are installed on the machine head 1 Stirring needle 2, shaft shoulder 3 are rotationally connected with machine head 1, bushing 4 is fixedly connected with machine head 1; heating collar 6 is sleeved on the outer wall of bushing 4.

[0034] The heating collar 6 can be a resistive heater. In the current embodiment, the heating collar 6 is an electromagnetic induction heater. The electromagnetic induction heater is a heating controller manufactured based on the principle of electromagnetic induction heating. The principle of electromagnetic induction heating is that the alternating current generated by the induction heating power supply generates an alternating magnetic field through an inductor (that is, a coil), and a magneticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com