Material extravehicular exposure friction wheel movement mechanism and on-orbit inspection device

A motion mechanism, friction wheel technology, applied in transportation and packaging, aerospace equipment, tools, etc., can solve the problems of contamination of optical lenses, sensor thermal control coatings, vacuum outgas effects, radiation heat transfer effects, etc., to achieve a strong environment Adaptability and reliability, high reliability and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

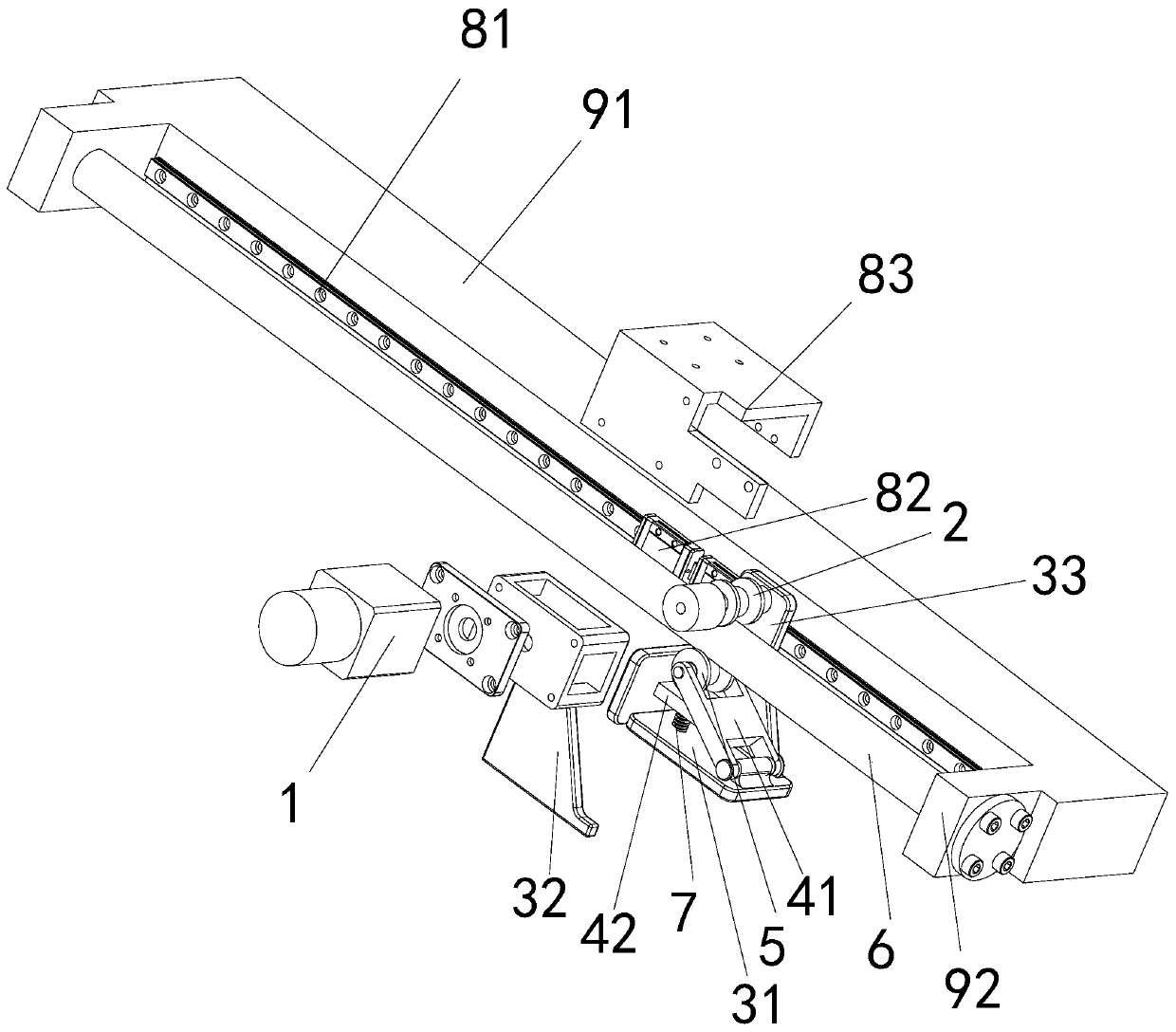

[0079] like Figure 1-4 As shown, a friction wheel movement mechanism exposed outside the cabin of a material, including:

[0080] drive mechanism 1,

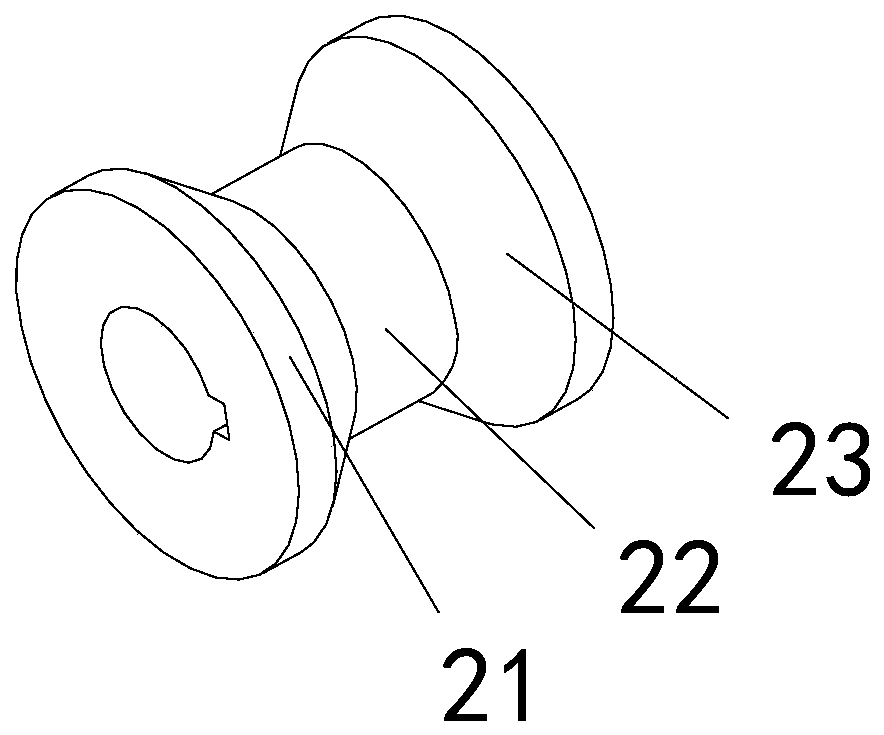

[0081] The active friction wheel 2 is fixedly installed on the output shaft of the drive mechanism 1;

[0082] The active pre-tightening base 3, the output shaft of the driving mechanism 1 and one end of the active pre-tightening base 3 are rotated and installed;

[0083] Driven pre-tightening base 4, one end of driven pre-tightening base 4 and the other end of active pre-tightening base 3 are rotated and installed, and the other end of driven pre-tightened base 4 is rotated and installed with driven friction wheel 5; The friction wheel 2 is arranged in parallel;

[0084] The friction rod 6 is sandwiched between the active friction wheel 2 and the driven friction wheel 5 components, and frictionally cooperates with the active friction wheel 2 and the driven friction wheel 5 respectively;

[0085] Preload spring 7, preload s...

Embodiment 2

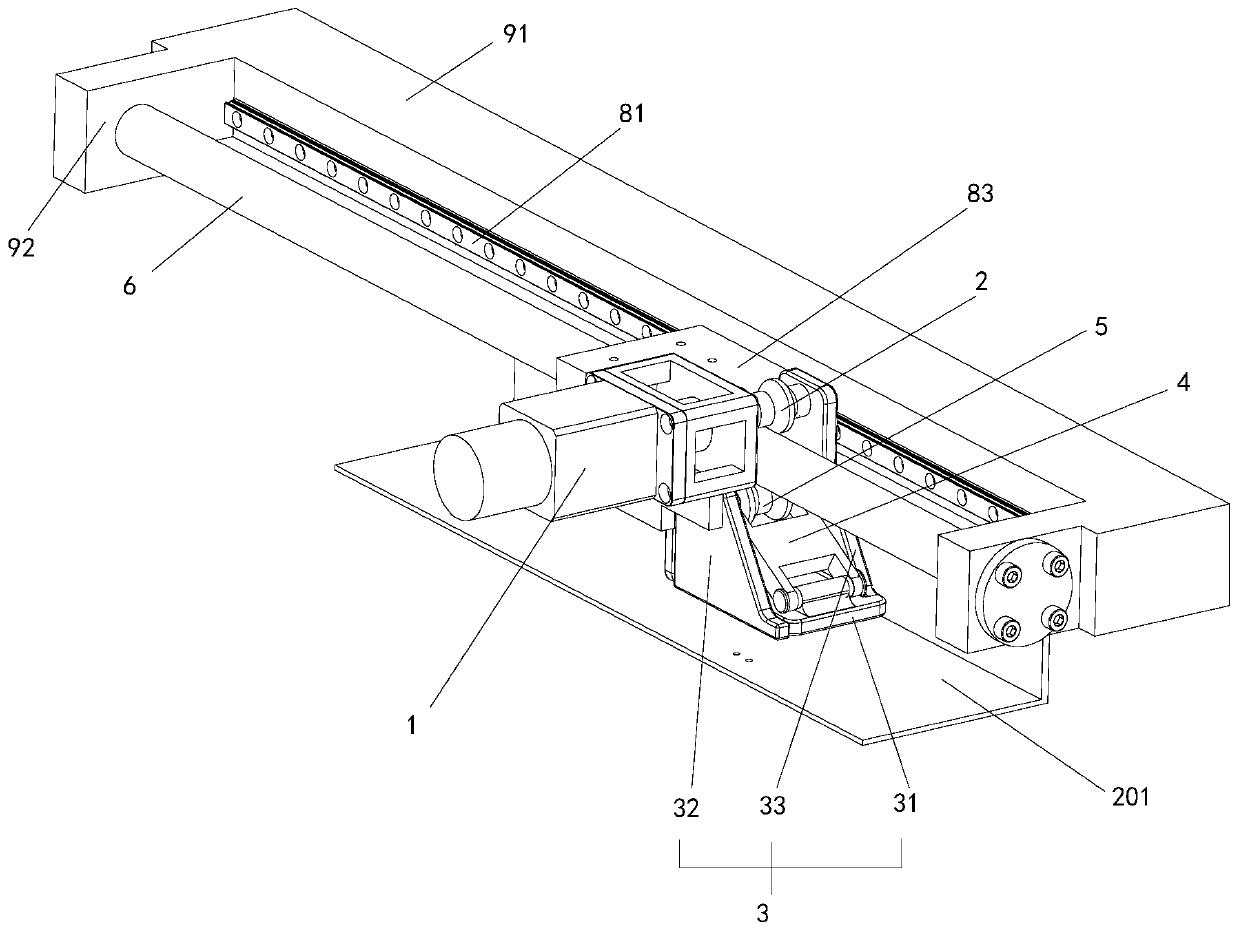

[0107] like Figure 4 As shown, an optical space on-orbit inspection device includes an inspection mechanism 100 and the above-mentioned material external exposure friction wheel movement mechanism, and the material external exposure friction wheel movement mechanism and the inspection mechanism 100 are both the same as the inspection mechanism 100. The exposed surface of the material is parallel, and the inspection mechanism 100 is fixedly connected with the movement mechanism of the friction wheel exposed outside the material cabin. The optical imaging module 101 is slidably installed on the inspection mechanism 100 , and the sliding direction of the optical imaging module 101 is perpendicular to the friction rod 6 .

[0108] Preferably, the structure of the inspection mechanism 100 is exactly the same as that of a friction wheel movement mechanism exposed outside the cabin of a material. The installation base 91 of the inspection mechanism 100 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com