High-temperature and high-pressure oil-gas well cleaning completion pipe string and process

A well completion string, high temperature and high pressure technology, applied in the direction of wellbore/well components, drill pipe, casing, etc., can solve the problems of out-of-control blowout, low pressure bearing capacity, and complex accident handling, so as to improve the internal pressure resistance strength , high pressure bearing capacity of the pipe string, and the effect of improving the efficiency of jam release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

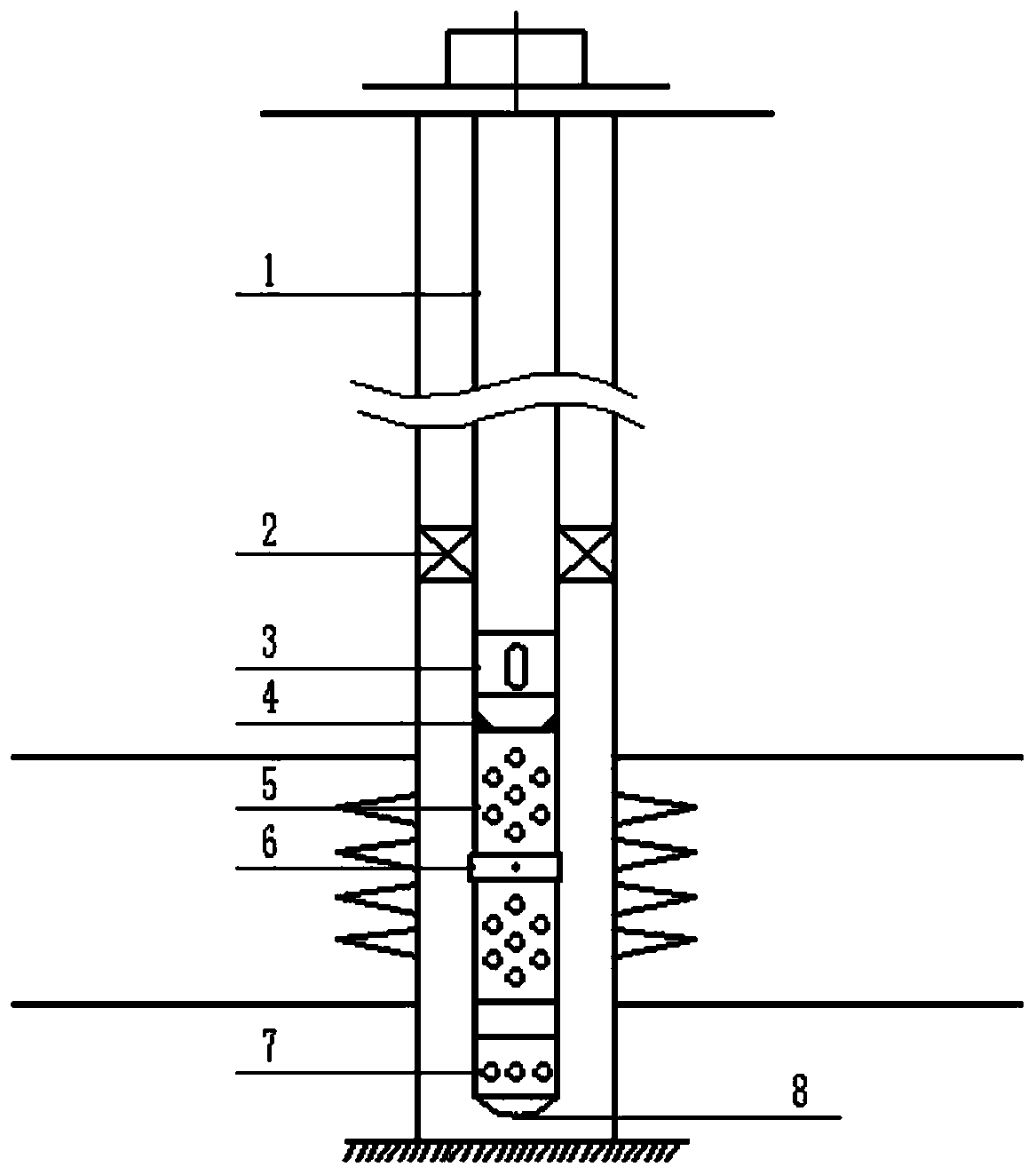

[0058] Such as figure 1 As shown, a safe, reliable and multi-functional clean completion string of a high temperature and high pressure oil and gas well is connected sequentially from top to bottom: tubing 1, packer 2, ball seat 4, fracturing sliding sleeve 3, high-strength temporary plugging screen 5 , perforated screen pipe 7, guide shoe 8. A high-pressure sealing safety joint is installed at intervals of 3-5 high-strength temporary plugging screens 5 in the string below the packer 2. The temporary plugging screen is located in the production zone, the fracturing sliding sleeve 3 is located in the upper boundary of the production zone, and the perforated screen 7 is located in the lower boundary of the production zone.

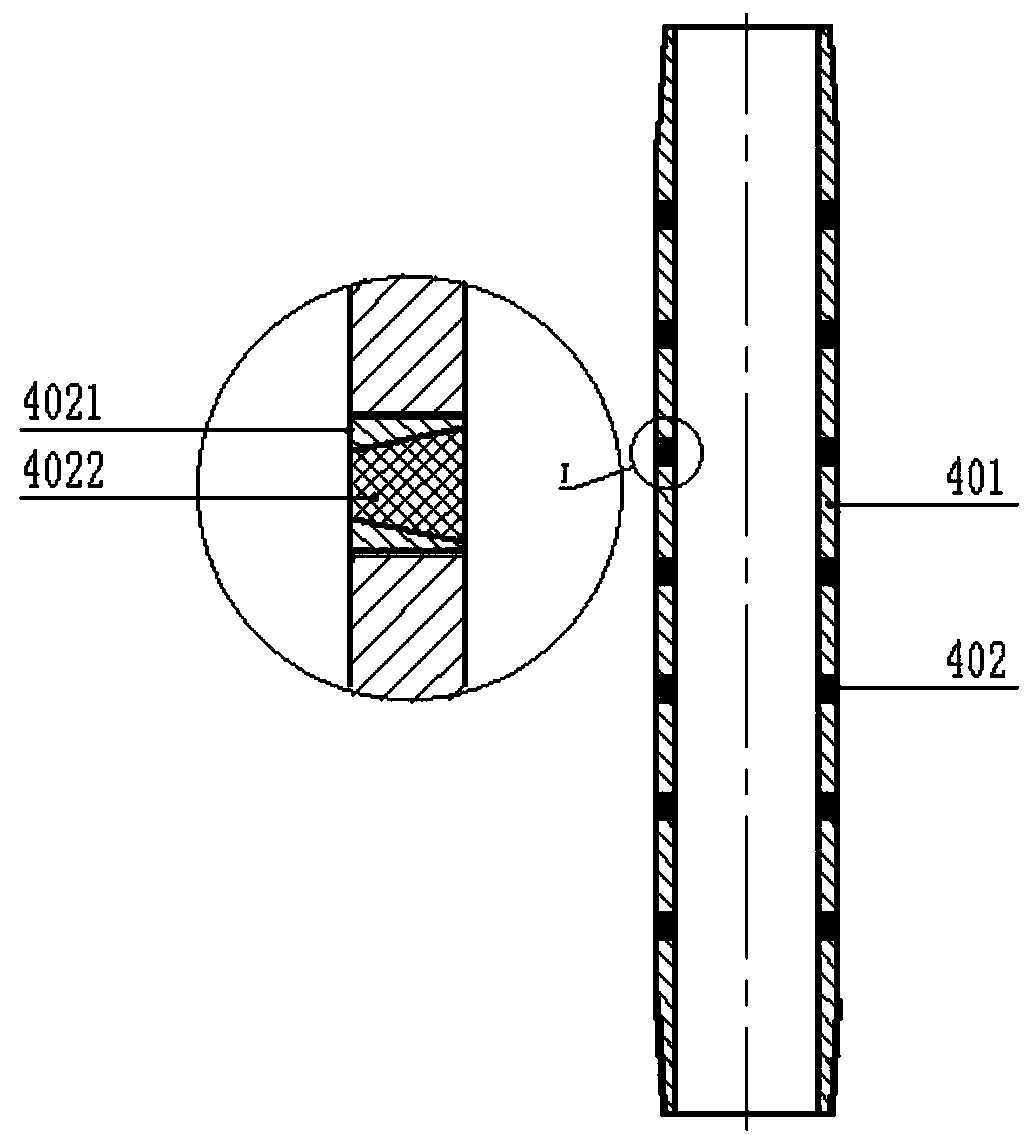

[0059] Such as figure 2 As shown, the high-strength temporary plugging screen 5 is composed of a base pipe 401 and a composite hole plug 402. The base pipe 401 is processed by the API standard oil pipe 1, and a plurality of holes are uniformly arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com