Multifunctional efficient cleaning basin

A multi-functional and high-efficiency technology, used in wellbore/well components, earth-moving, construction, etc., to solve problems such as sand, cement, and milling debris easily re-inhaled into the well, and the pool has no partitions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An oil field refers to a specific area where crude oil is produced, while an oil field well site refers to the flat field in front of the drilling platform, which is used to discharge drill pipes and casings, park cement trucks during well cementing, and park logging vehicles during well logging, etc. The length of the well site The size and area should ensure that when the drilling equipment is installed, the derrick can be leveled and various drilling equipment, hoisting machinery and vehicles can be parked and turned.

[0030] The cleaning pool used in downhole operations has the problem that there is no partition in the middle of the pool during drilling, punching and milling, and the sand, cement, and milling debris washed out of the well are easily sucked into the well again.

[0031] Therefore, aiming at the above problems, the present invention provides a multi-functional and high-efficiency cleaning pool.

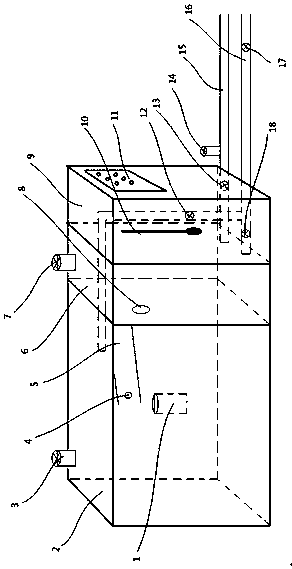

[0032] Specific as figure 1 As shown, a multifunction...

Embodiment 2

[0044] The embodiment of the present invention is further limited on the basis of embodiment 1.

[0045] see figure 1 A diversion tank 5 is installed inside the sedimentation tank 2 at the junction of the sedimentation tank 2 and the overflow circulation tank 6, and a magnet 4 is arranged inside the diversion tank 5, and is arranged inside the sedimentation tank 2 at the lower end of the outlet of the diversion tank 5 There is a sampling barrel 1 .

[0046] The diversion groove 5 is arranged in an inclined shape near the end of the overflow circulation pool 6 .

[0047] The sand-carrying fluid returned from drilling, punching, milling and milling flows into the diversion tank 5 through the blowout pipeline 16, and the magnet 4 arranged inside the diversion tank 5 and the sampling bucket 1 provided below the outlet cooperate with each other to realize The return matter in the well can flow into the sampling barrel 1 for sampling. If there is iron-containing substance in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com