Conveying, shearing and crimping integrated device for cable end

A cable terminal and male connector technology, which is applied in the field of conveying, shearing, and crimping integrated devices, can solve the problems that the vibrating plate cannot control the orientation of the male connector's center conductor, and it is inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

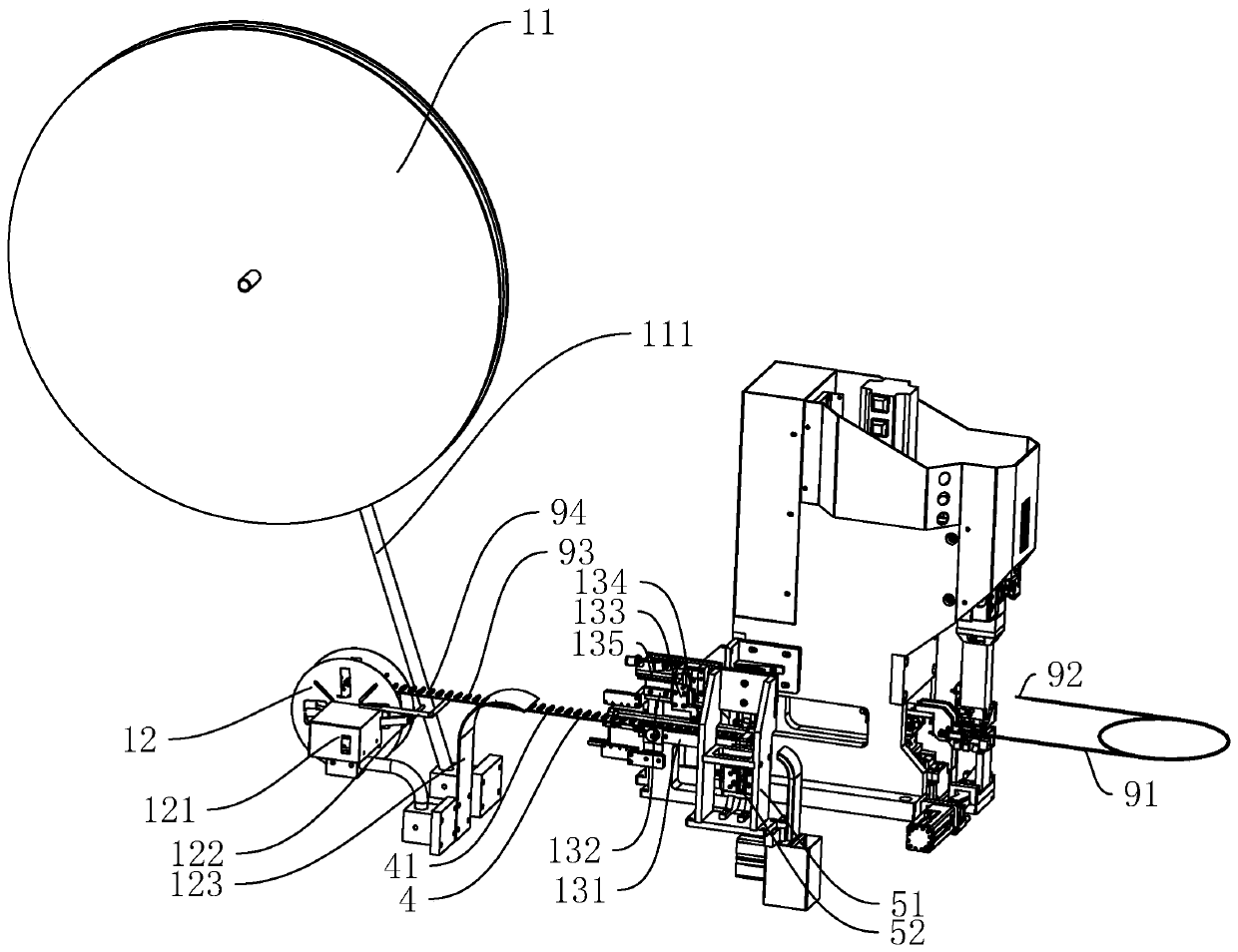

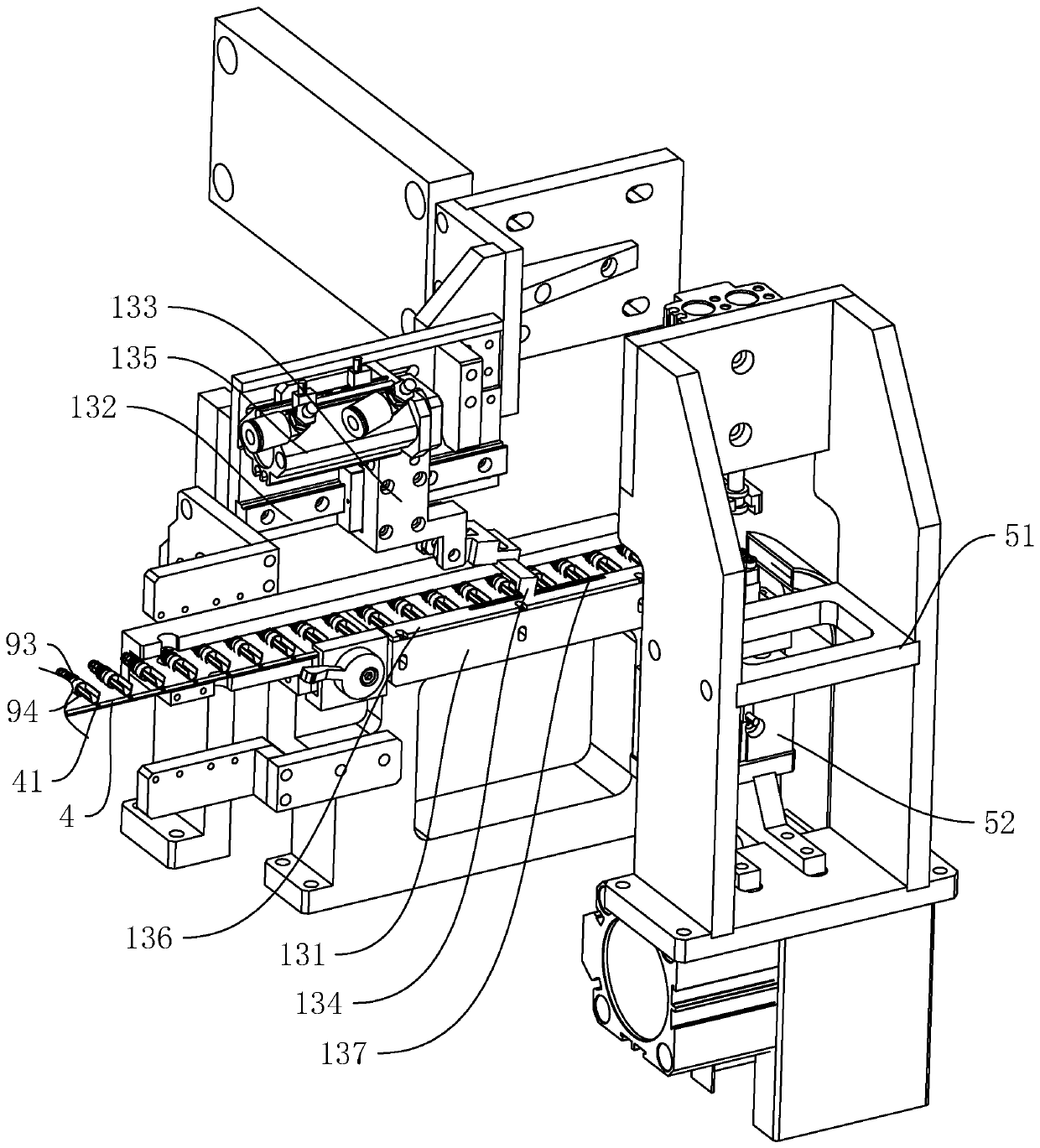

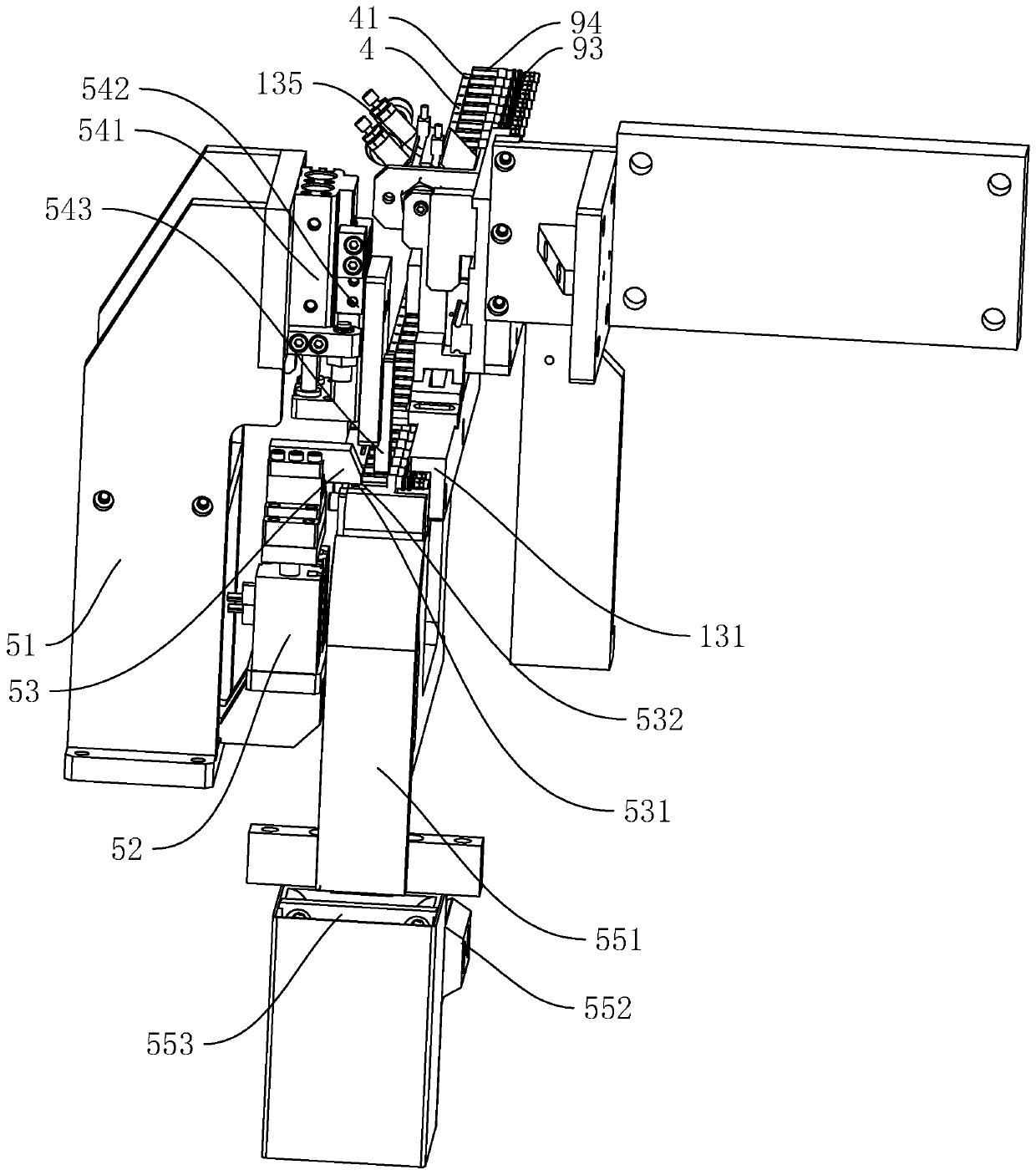

[0043] Conveying, shearing and crimping all-in-one unit for cable lugs, e.g. figure 1 , figure 2 , image 3 As shown, it includes a feeding mechanism, a plug-in mechanism, a stamping mechanism, a material strip 4 and a shearing mechanism. The material strip 4 is provided with through holes 41 at equal intervals along the length direction, and the male center conductors are processed and formed on the material strip 4 at equal intervals; The mechanism includes a male material tray 11, a roll paper tray 12, and a push assembly, and the push assembly includes a straight slot seat 131, a forward rail 132 that is parallel supported and fixed directly above the straight slot seat 131, and a front rail 132 that is slidably connected to the front rail 132. The forward slider 133, the hook 134 rotatably connected to the forward slider 133, and the forward cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com