Cable joint peeling device for electric power

A cable joint and power technology, applied in the field of power, can solve the problems of slow insulation speed, uncontrollable cutting depth, affecting the efficiency of power construction work, etc., and achieves the effect of strong function, simple structure and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

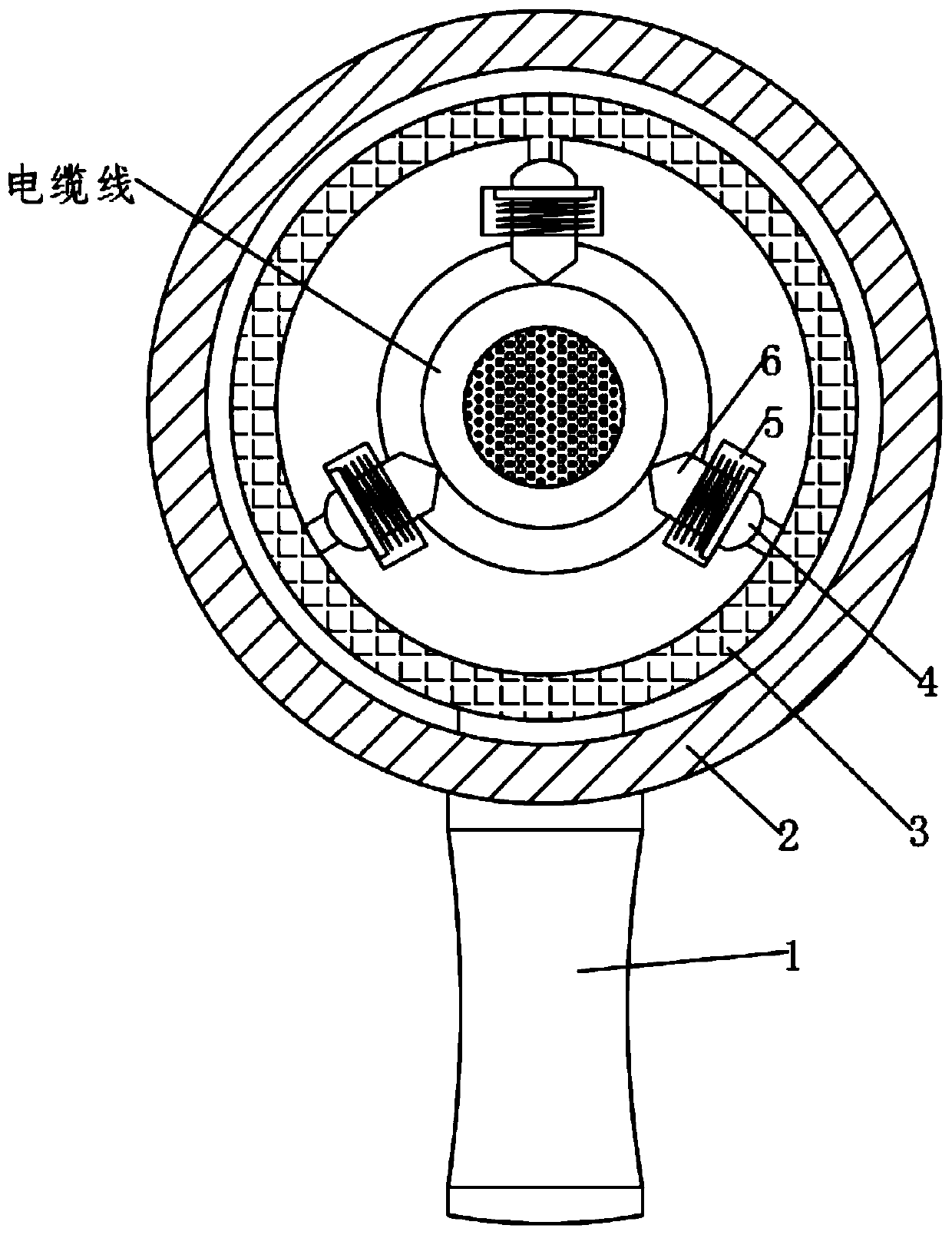

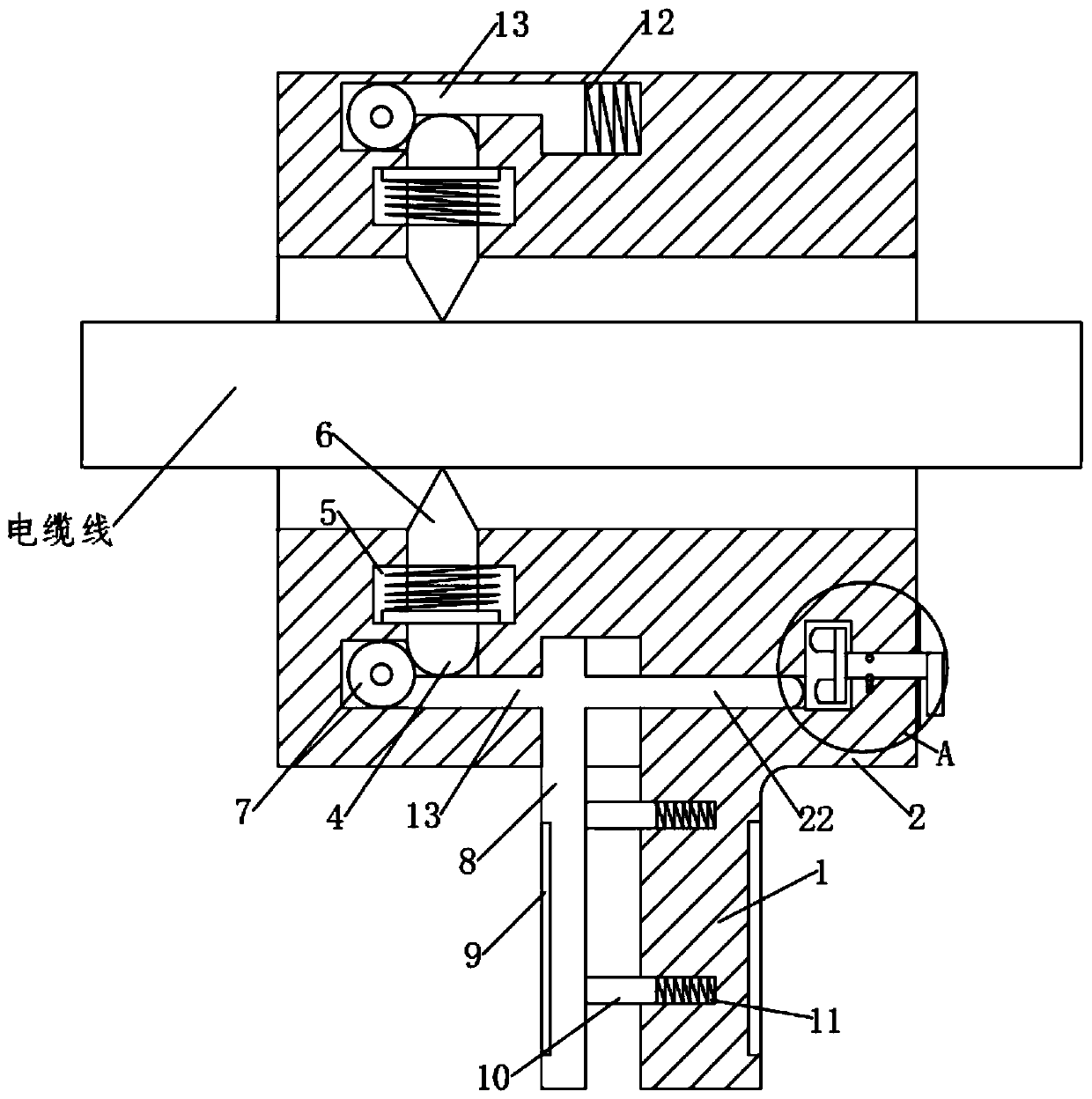

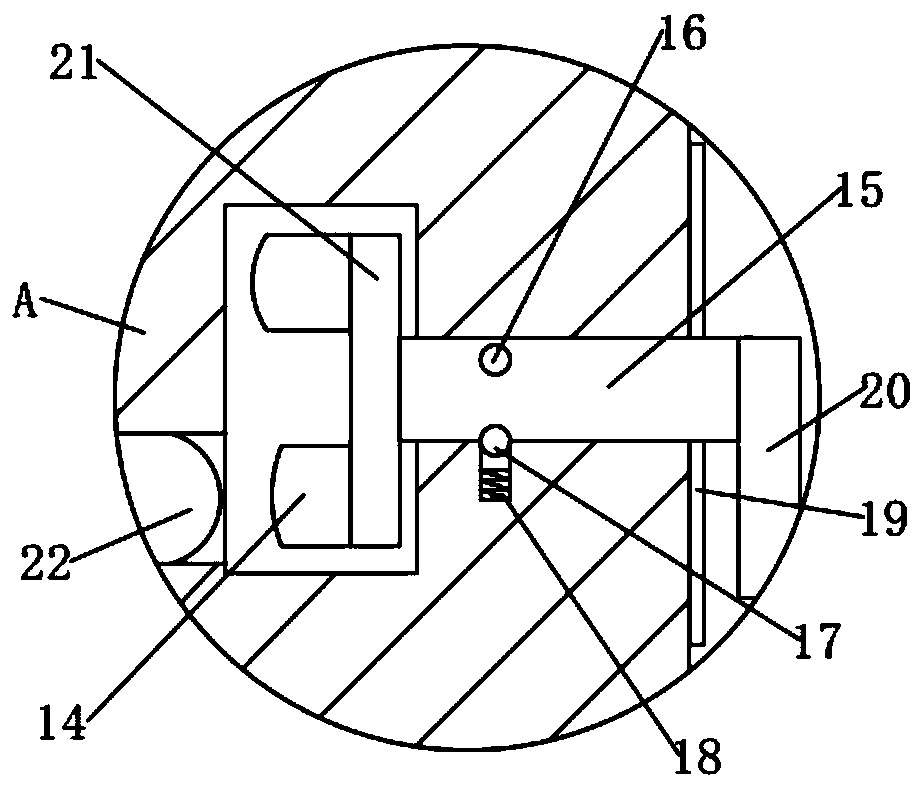

[0022] see Figure 1-4 , a cable joint peeling device for electric power, including a fixed handle 1, a box body 2, a cutter head 6 and a movable handle 8; wherein the fixed handle 1 is fixedly installed on the box body 2, and the movable handle 8 Slidingly installed on the box body 2, a ring rod 3 is slidably installed in the box body 2, and the movable handle 8 is fixedly connected with the ring rod 3, and further drives the movable handle 8 when the movable handle 8 is moved. The circular rod 3 described above moves, the cutter head 6 is slidably installed in the box body 2 through the cutter bar 4, the box body 2 is provided with a chute 5, and the cutter bar 4 is slidably arranged in the chute 5 Inside; said annular bar 3 is fixedly equipped with connecting rod 13, and the end of said connecting rod 13 is rotated and installed with roller 7; The end touches, and then when the movable handle 8 is pressed, the roller 7 is further driven to move, and the roller 7 squeezes t...

Embodiment 2

[0031] In order to further improve the use effect of the device, this embodiment has made the following improvements on the basis of the first embodiment. The improvement is that the fixed handle 1 and the movable handle 8 are equipped with rubber pads 9, and the The rubber pad 9 improves the grip feeling of the device when it is used externally while effectively realizing insulation.

[0032] The working principle of this embodiment: by arranging the rubber pad 9 on the fixed handle 1 and the movable handle 8, the insulation is effectively realized and the grip feeling of the device is improved when the device is used externally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com