Communication protocol message structure and its application applied to eol automatic offline test

A protocol and message technology, which is applied in the field of EOL automated testing, can solve the problems of inconsistent test communication protocols, high labor cost, and long debugging cycle, so as to achieve the effect of improving versatility, improving efficiency, and shortening the debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

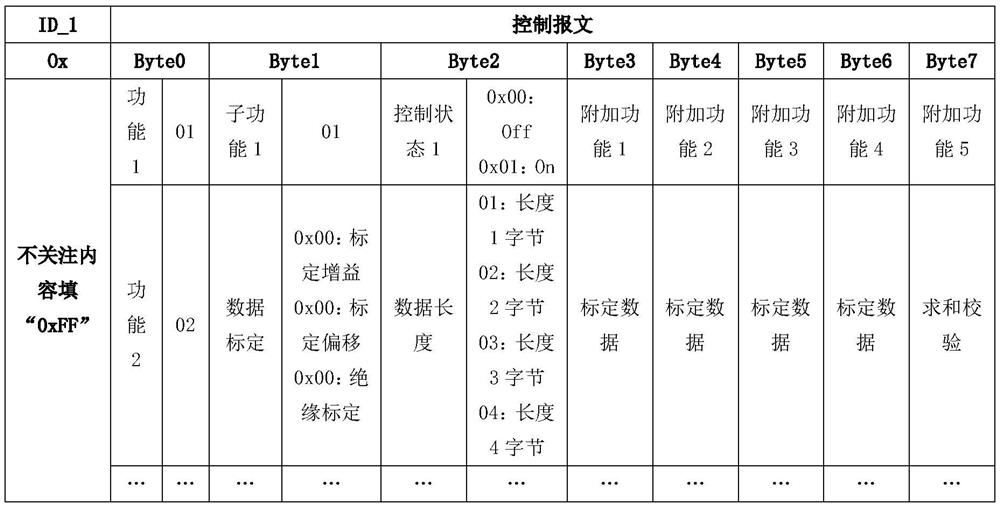

[0021] The ID of the control message is 18FFFFFF (this ID is used for the convenience of the full-text control message). There are 6 high-side drivers in the controller. It is necessary to make the high-side 3 drive close to measure the output of this channel. The ID and content of the control request feedback message are :

[0022] 0x18FFFFFF 02 03 01 FF FF FF FF FF

[0023] Note: 02 represents the high-side drive function code, 03 represents the control of the third high-side drive, and 01 represents the control of the high-side output state as the on state;

[0024] If you need to turn on the diagnosis of the high side to test the diagnosis function during the test, you can define the diagnosis switch in the 4th byte, and the control request feedback message is:

[0025] 0x18FFFFFF 02 03 01 01 FF FF FF FF

[0026] Similarly, the following byte resources can enable other functions at the same time

Embodiment 2

[0028] It is necessary to calibrate the current gain of the controller, and the calibration data is 90000, so the pleading control message is:

[0029] 0x18FFFFFF 06 00 04 01 5F 90 00 FF

[0030] Among them, 06 represents the current test function, 00 represents the calibration gain, 04 represents the calibration length is 4 bytes, and 01 5F 9000 is the calibration data.

[0031] As shown in Table 2, the frame structure of the feedback message includes multiple byte columns distributed along the row direction. The multiple byte columns include at least one feedback function byte column and one functional test result byte column. The feedback function byte column It is the feedback function information corresponding to the control message one by one. The function test result byte column is the feedback function test result data (which can be information such as voltage, current, resistance or other status), and each feedback data according to the size of the feedback data Can ...

Embodiment 3

[0037] There are a total of 6 high-side drivers of the controller. It is necessary to close the high-side 3 drivers to measure the output voltage of this channel. Then the control request feedback message sending information is:

[0038] 0x18FFFFFF 02 03 01 FF FF FF FF FF

[0039] The feedback information of the feedback message is:

[0040] 0x18000000 02 00 00 00 00 00 00 00

[0041] 0x18111111 02 00 00 00 00 F6 2E 00

[0042] At this time, the representative feedback function code 02 indicates the feedback high-side drive function, and F6 2E is the output voltage value of the feedback high-side drive 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com