Traction device of compensation chain plastic dipping equipment

A technology of traction device and compensation chain, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of affecting the smooth operation of the production line, not easy to convey stably, and complex shapes, and achieve high friction and low friction. , the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

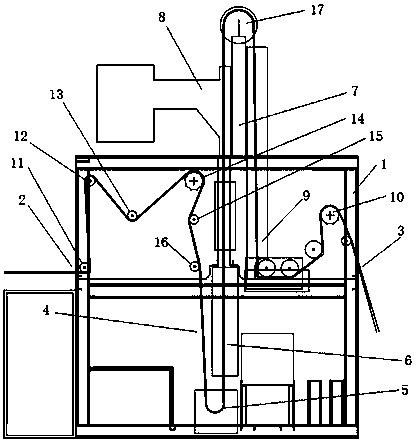

[0032] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, a traction device of a compensation chain dipping equipment, the compensation chain dipping equipment includes a frame 1, the left side of the middle of the frame is a chain inlet 2, and the right side is a chain outlet 3, and a drive motor is installed outside the chain outlet , pulling the chain under the guidance of the traction device provided in the frame 1, the chain passes through the intermediate frequency heating zone 4, the dipping zone 5, the heating zone 6, the heat preservation zone 7, and the cooling zone 8 / 9 in sequence, from the Chain outlet 3 passes through and completes dipping.

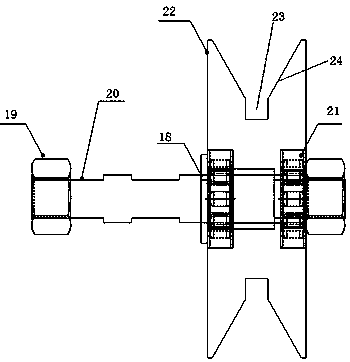

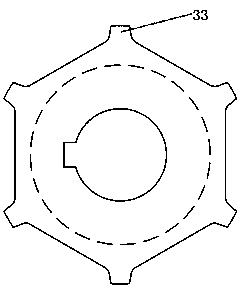

[0034] Such as Figure 1~Figure 8 As shown, the driving motor drives the driving wheel of the driving wheel 10 to rotate, and the rim of the driving wheel 10 is fixed on the shaft 32, which is transmitted through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com