A kind of silicon dioxide film material with high insulation resistance and preparation method thereof

A technology of silicon dioxide and thin film materials, which is applied to the surface pretreatment, devices for coating liquid on the surface, coatings, etc. The effect of large-scale industrial production, simple preparation method and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

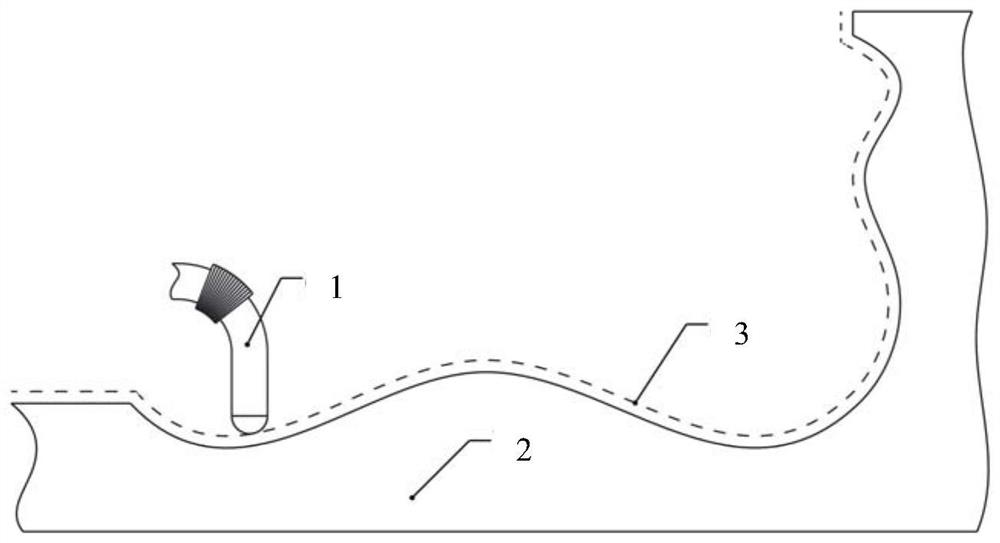

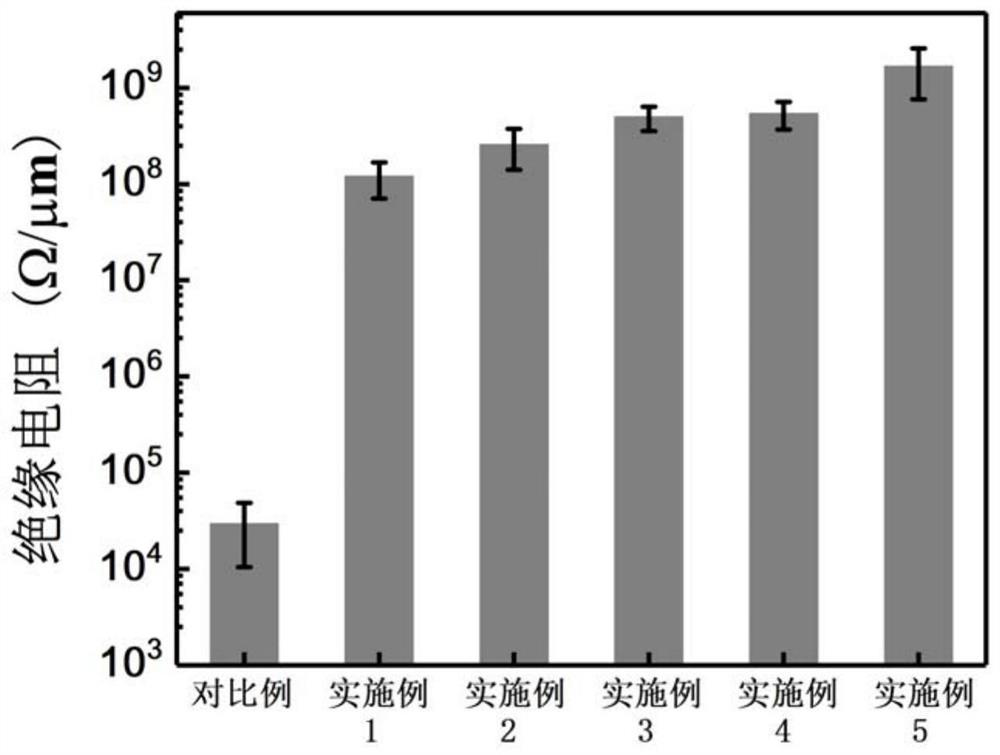

[0033] A method for preparing a silicon dioxide thin film material with high insulation resistance, the preparation method is: using an atmospheric pressure discharge device at room temperature, using a metal substrate with any shape as the base material, using argon with a purity of 99.99% as the discharge gas and carrier Gas, using oxygen with a purity of 99.99% as the reaction gas, and silicon tetrachloride with a purity of 99.99% as the reaction liquid, carry out atmospheric pressure discharge to prepare a silicon dioxide film, and maintain a constant distance between the nozzle of the atmospheric pressure discharge device and the surface of the substrate, and obtain The thickness of silicon dioxide film is 1.31μm, and its insulation resistance is 1.55±0.53×10 8 Ω, calculated according to the linear relationship between the insulation resistance of the silicon dioxide film material and its thickness, the insulation resistance of the silicon dioxide film material is 1.19 ± 0...

Embodiment 2

[0036] A method for preparing a silicon dioxide thin film material with high insulation resistance, the preparation method is: using an atmospheric pressure discharge device at room temperature, using a metal substrate with any shape as the base material, using argon with a purity of 99.99% as the discharge gas and carrier Gas, using oxygen with a purity of 99.99% as the reaction gas, and silicon tetrachloride with a purity of 99.99% as the reaction liquid, carry out atmospheric pressure discharge to prepare a silicon dioxide film, and maintain a constant distance between the nozzle of the atmospheric pressure discharge device and the surface of the substrate, and obtain The thickness of silicon dioxide film is 4.86μm, and its insulation resistance is 1.25±0.14×10 9 Ω, calculated according to the linear relationship between the insulation resistance of the silicon dioxide film material and its thickness, the insulation resistance of the silicon dioxide film material is 2.57 ± 0...

Embodiment 3

[0039] A method for preparing a silicon dioxide thin film material with high insulation resistance, the preparation method is: using an atmospheric pressure discharge device at room temperature, using a metal substrate with any shape as the base material, using argon with a purity of 99.99% as the discharge gas and carrier Gas, using oxygen with a purity of 99.99% as the reaction gas, and silicon tetrachloride with a purity of 99.99% as the reaction liquid, carry out atmospheric pressure discharge to prepare a silicon dioxide film, and maintain a constant distance between the nozzle of the atmospheric pressure discharge device and the surface of the substrate, and obtain The thickness of silicon dioxide film is 5.38μm, and its insulation resistance is 2.67±0.32×10 9 Ω, calculated according to the linear relationship between the insulation resistance of the silicon dioxide film material and its thickness, the insulation resistance of the silicon dioxide film material is 4.96 ± 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap