Lightweight high-temperature-resistant lightning-proof composite board and forming method

A composite plate, lightning protection technology, applied in the field of materials, can solve the problems of heavy weight, complex process, poor corrosion resistance and lightning protection, etc., to achieve light weight, good lightning protection, corrosion resistance and manufacturability excellent effect

Inactive Publication Date: 2020-05-01

XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the domestic aviation field, carbon fiber composite materials, metal mesh, and film composite plates are widely used, or lightning protection methods such as flame spraying aluminum are used on the surface of the parts. The disadvantages are: 1. Heavy weight and high cost

The density of metal aluminum mesh and adhesive film is relatively high, and the thickness of flame sprayed aluminum protective layer is relatively large, resulting in a large increase in structural weight; in addition, the mixing process is complicated; special equipment is required for heating and vulcanization, resulting in high cost

2. The process is complex and easy to deform

It is necessary to manually cover the metal mesh and film, lay the insulating glass cloth layer, flame spray the aluminum, apply the sealing agent, and apply the ground paint. The net is easy to wrinkle, deform, or even break

3. Poor corrosion resistance and lightning protection

Due to the need for surface treatment, the bonding force is not good, and it needs to be glued, which is easy to corrode, and the lightning protection effect is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0036] Compared with the metal mesh of the same thickness in Example 1, the lightning protection effect is improved by about 20%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

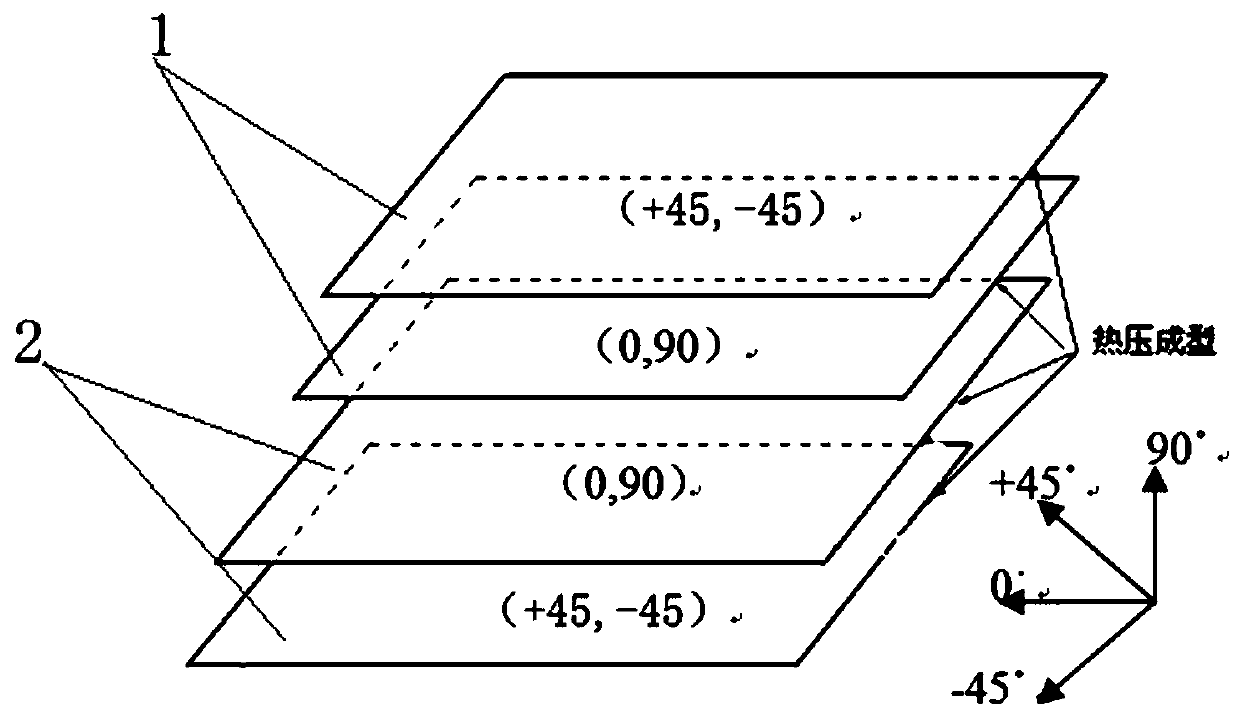

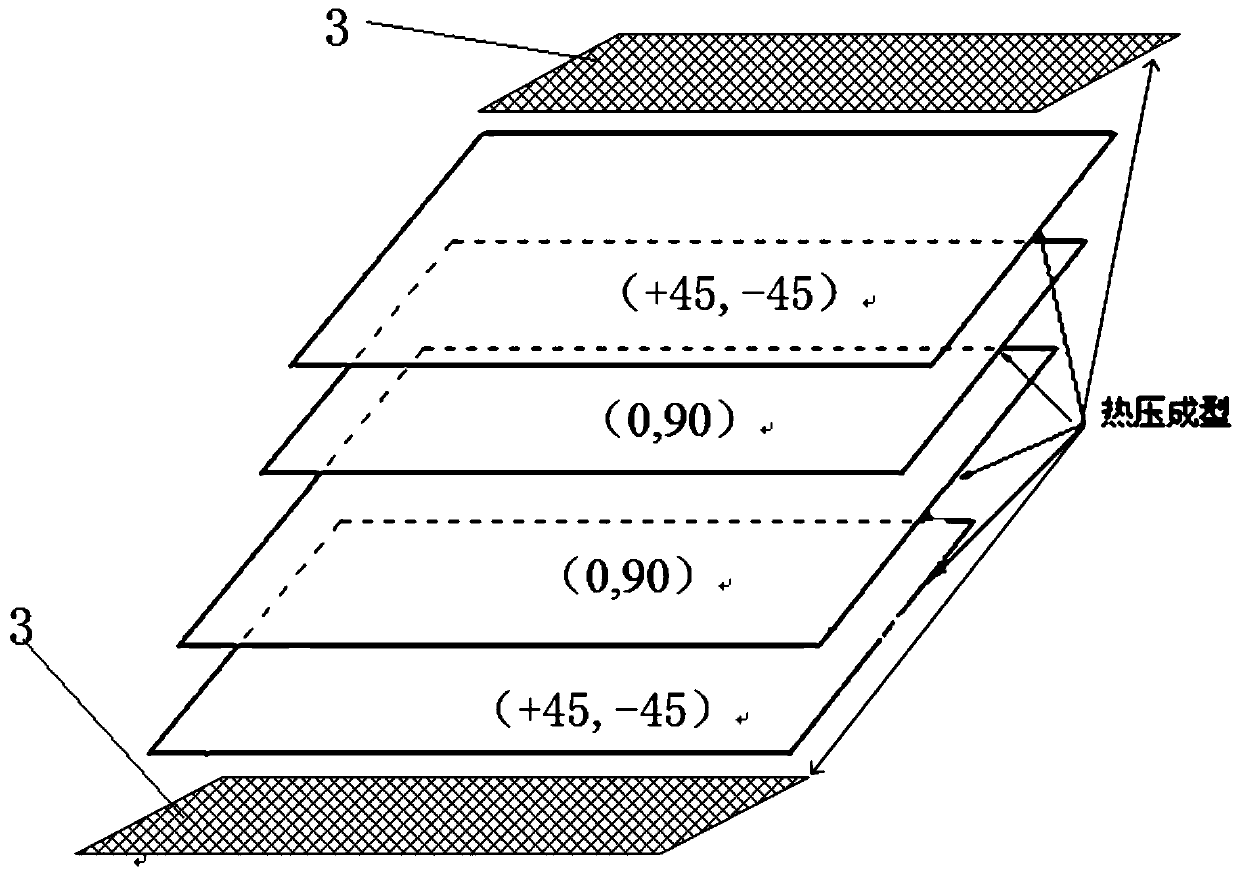

The invention discloses a lightweight high-temperature-resistant lightning-proof composite board and a forming method. The lightweight high-temperature-resistant lightning-proof composite board comprises two layers of upper panels and two layers of lower panels which are laid in a balanced and symmetrical sequence according to a laying proportion of [(+45, -45) / (0, 90)]S; the upper panel on the outermost layer and the lower panel on the outermost layer are each provided with a layer of a lightning-proof copper net adhesive film; and each lightning-proof copper net adhesive film is formed by compounding a copper net and an adhesive film. The formed composite board provided by the invention is light in weight, good in lightning-proof performance, excellent in corrosion resistance and manufacturability and capable of meeting the requirements of aviation products.

Description

technical field [0001] The invention belongs to the field of material technology, and in particular relates to a light-weight, high-temperature-resistant and lightning-proof composite plate and a forming method. Background technique [0002] The light-weight high-temperature-resistant and lightning-proof plate has obvious effects on realizing the multiple functions of the material and reducing the weight of the structure. At present, the domestic construction industry widely uses lightning protection plates composed of metal protective nets and flame sprayed aluminum, and their weight and thickness are not suitable for their requirements for weight reduction and structural size. In the domestic aviation field, plates made of carbon fiber composite materials, metal mesh, and film are widely used, or lightning protection methods such as flame spraying aluminum are used on the surface of the parts. The disadvantages are: 1. Heavy weight and high cost. The density of metal alum...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B9/00B32B9/04B32B5/02B32B5/26B32B15/20B32B15/02B32B7/08B32B33/00B32B37/10B32B37/06B29C70/34

CPCB29C70/34B32B5/02B32B5/26B32B7/08B32B33/00B32B37/06B32B37/10B32B2250/05B32B2250/40B32B2262/103B32B2262/106B32B2307/70B32B2307/752

Inventor 高丽红钟振全党婧贺辉

Owner XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com