Annular warehouse logistics intelligent handling equipment adopting circle distance trajectory pushing, padding and press buckling

A technology for warehousing logistics and intelligent handling, which is applied in the direction of conveyor objects, transportation and packaging, and conveyor control devices. It can solve problems such as insufficient mechanical structure, insufficient hinge strength, and affecting the deformation of logistics boxes, so as to improve flexible lifting. The effect of placing objects, ensuring the tightness of angular velocity, and increasing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

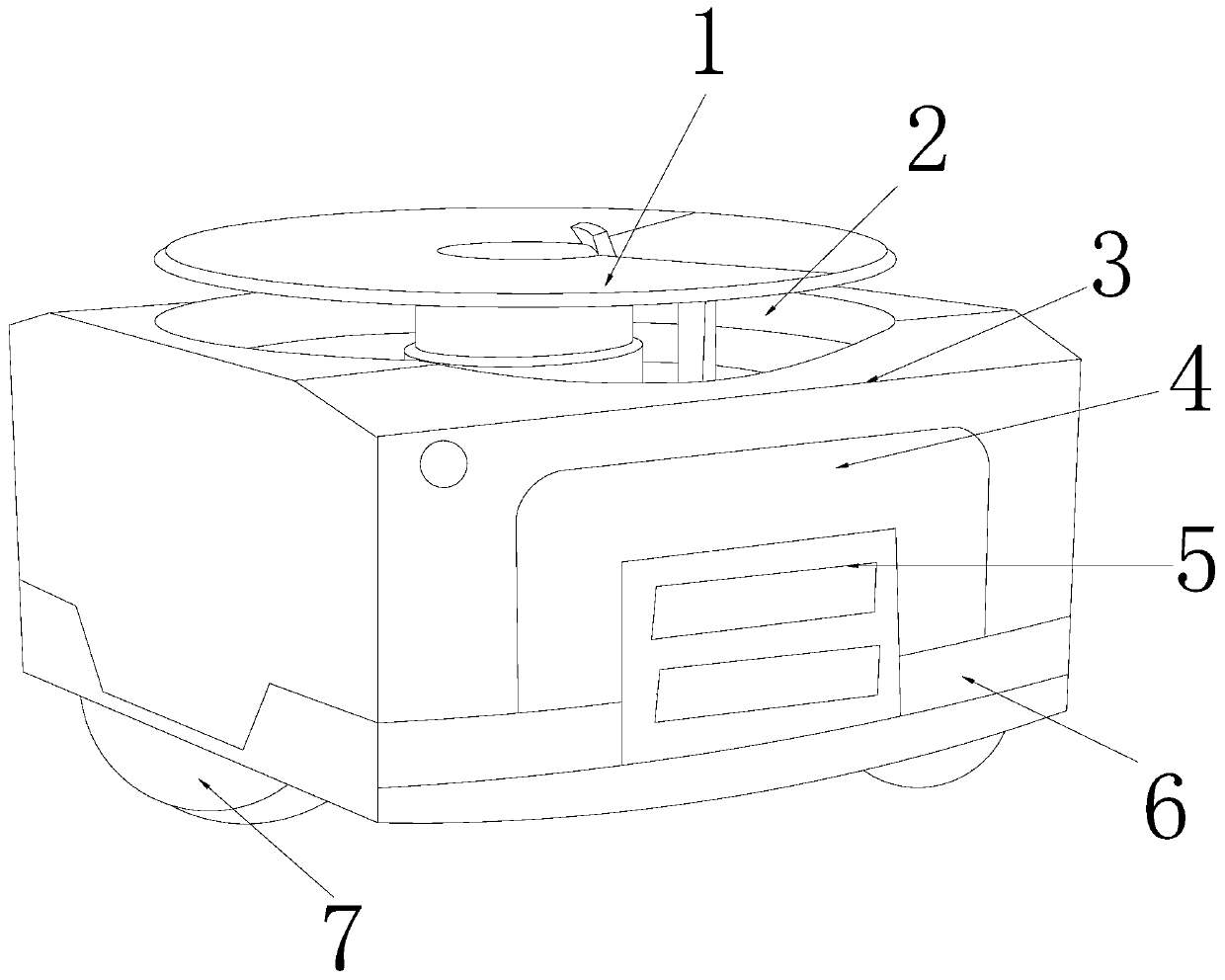

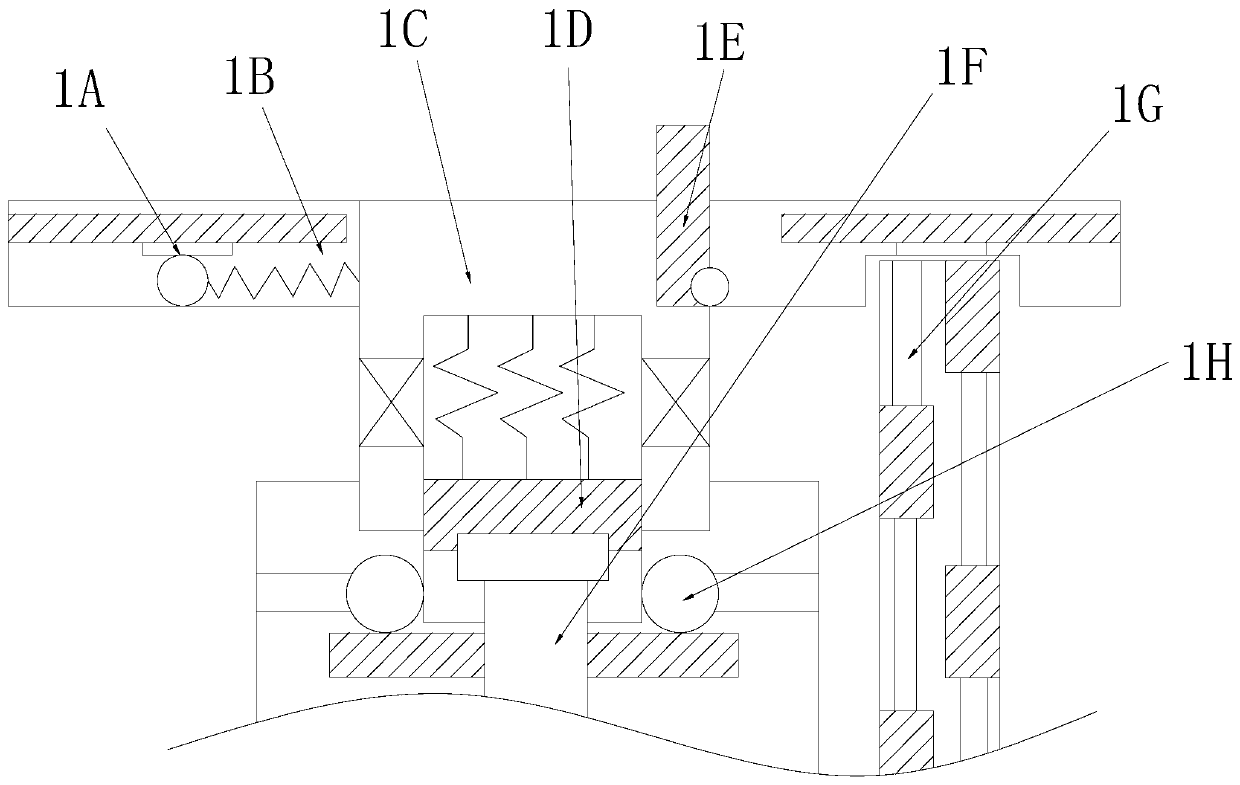

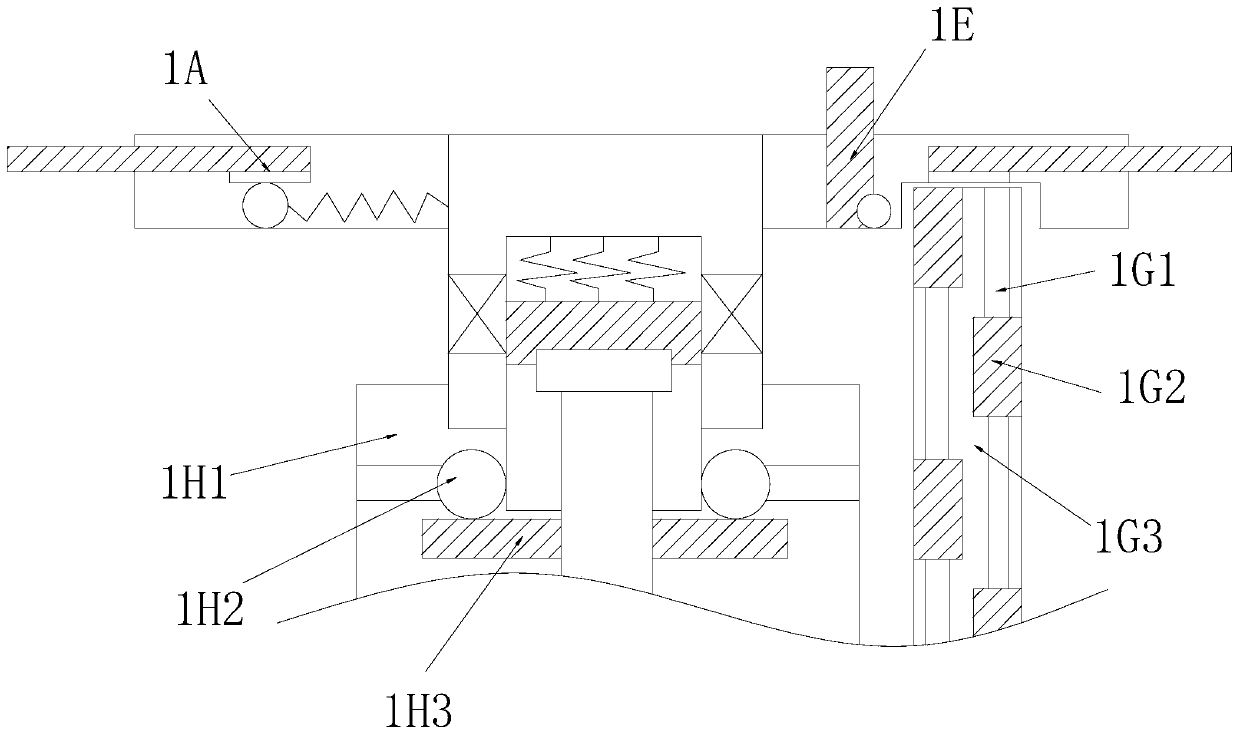

[0031] see Figure 1-Figure 7, the present invention provides a ring-shaped storage and logistics intelligent handling equipment that pushes and presses buttons with a circular distance track. 5. Bottom frame seat plate 6, moving wheel 7, the plunger tray bracket 1 is installed inside the wide-mouth barrel groove 2 and the axes are collinear, and the wide-mouth barrel groove 2 is inserted into the inside of the shell body 3 , the front baffle 4 is closely attached to the front side of the housing body 3, the front baffle 4 is in close contact with the scanning detection board 5 and is on the same vertical plane, and the scanning detection board 5 is embedded in the The front ends of the bottom frame seat plate 6 are perpendicular to each other, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com