A kind of aliphatic water-reducer made from lignosulfonate waste water and its synthesis process

A technology of lignosulfonate and aliphatic water reducing agent, which is applied in the field of concrete water reducing agent, can solve the problems of digesting lignosulfonate wastewater, unable to prepare lignosulfonate water reducing agent, etc. Reasonable utilization of resources, improvement of water reduction effect, effect of improving reaction efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

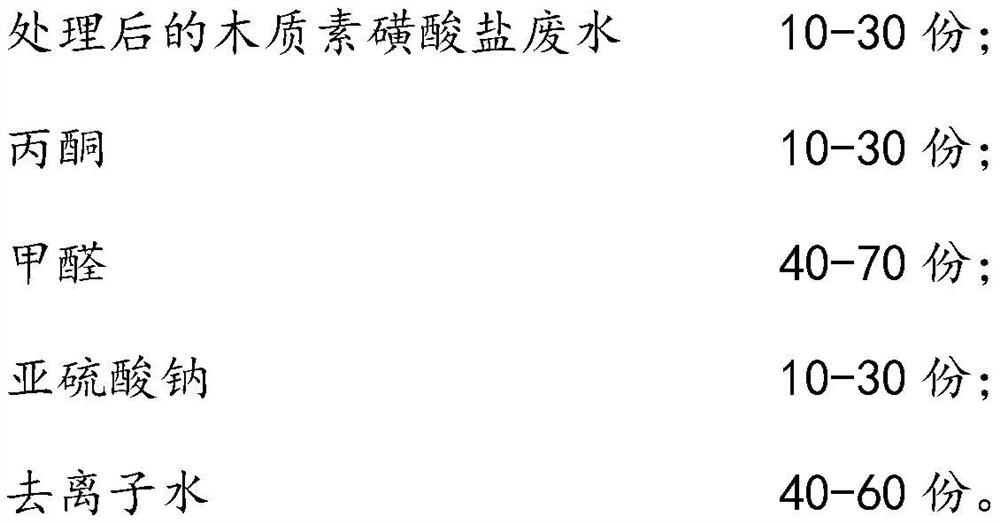

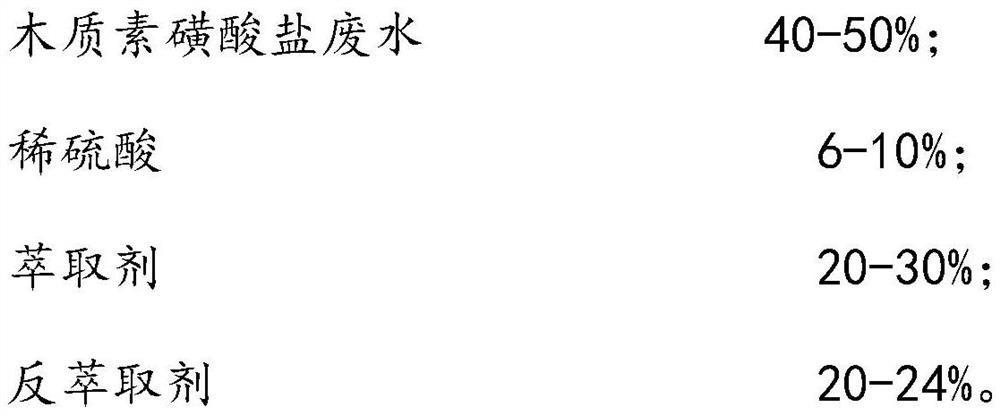

Method used

Image

Examples

Embodiment 1

[0059] The difference between embodiments 10-13 and embodiment 1 is that the extractant comprises the following raw materials in weight percentage:

[0060]

[0061] The difference between Embodiment 14-17 and Embodiment 1 is that the stripping agent comprises the following raw materials in weight percentage:

[0062]

[0063]

[0064] The difference between Embodiment 18-21 and Embodiment 1 is that the heating temperature in step S2 is as shown in the table below:

[0065] Example Example 18 Example 19 Example 20 Example 21 temperature / ℃ 43 45 47 50

[0066] The difference between embodiment 22-25 and embodiment 1 is that the reaction time in step S2 is as shown in the table below:

[0067] Example Example 22 Example 23 Example 24 Example 25 time / h 0.5 0.7 1 1.3

[0068] The difference between Embodiment 26-29 and Embodiment 1 is that the heating temperature in step S3 is as shown in the table below:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com