Flexible damping bearing bush

A bearing bushing and bushing technology, applied in the direction of bearing components, shafts and bearings, springs/shock absorbers, etc., can solve problems such as failure, fatigue fracture and vibration reduction performance, and affect the normal operation of bearings, so as to protect machinery and reduce Amplitude, the effect of excellent vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

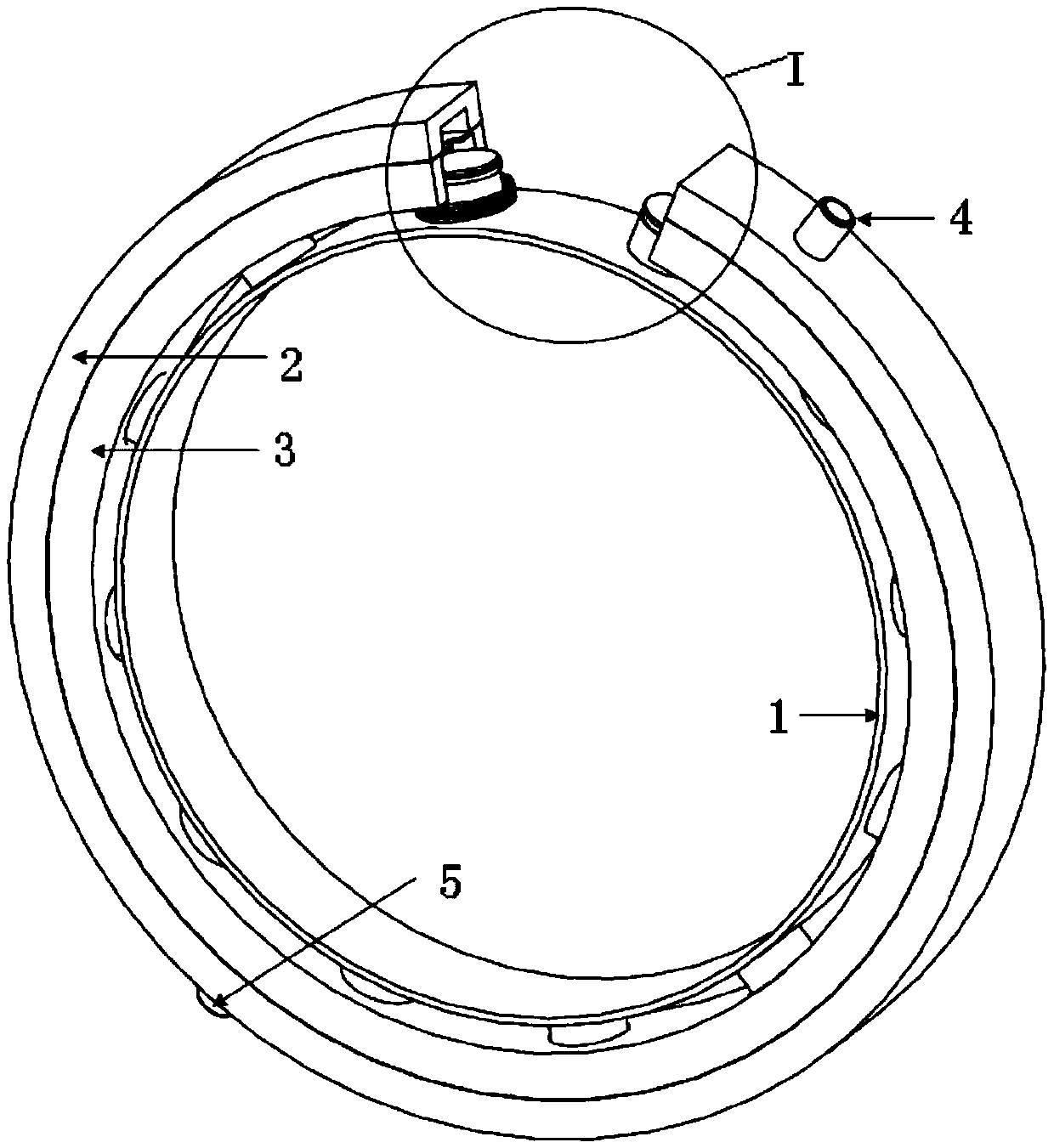

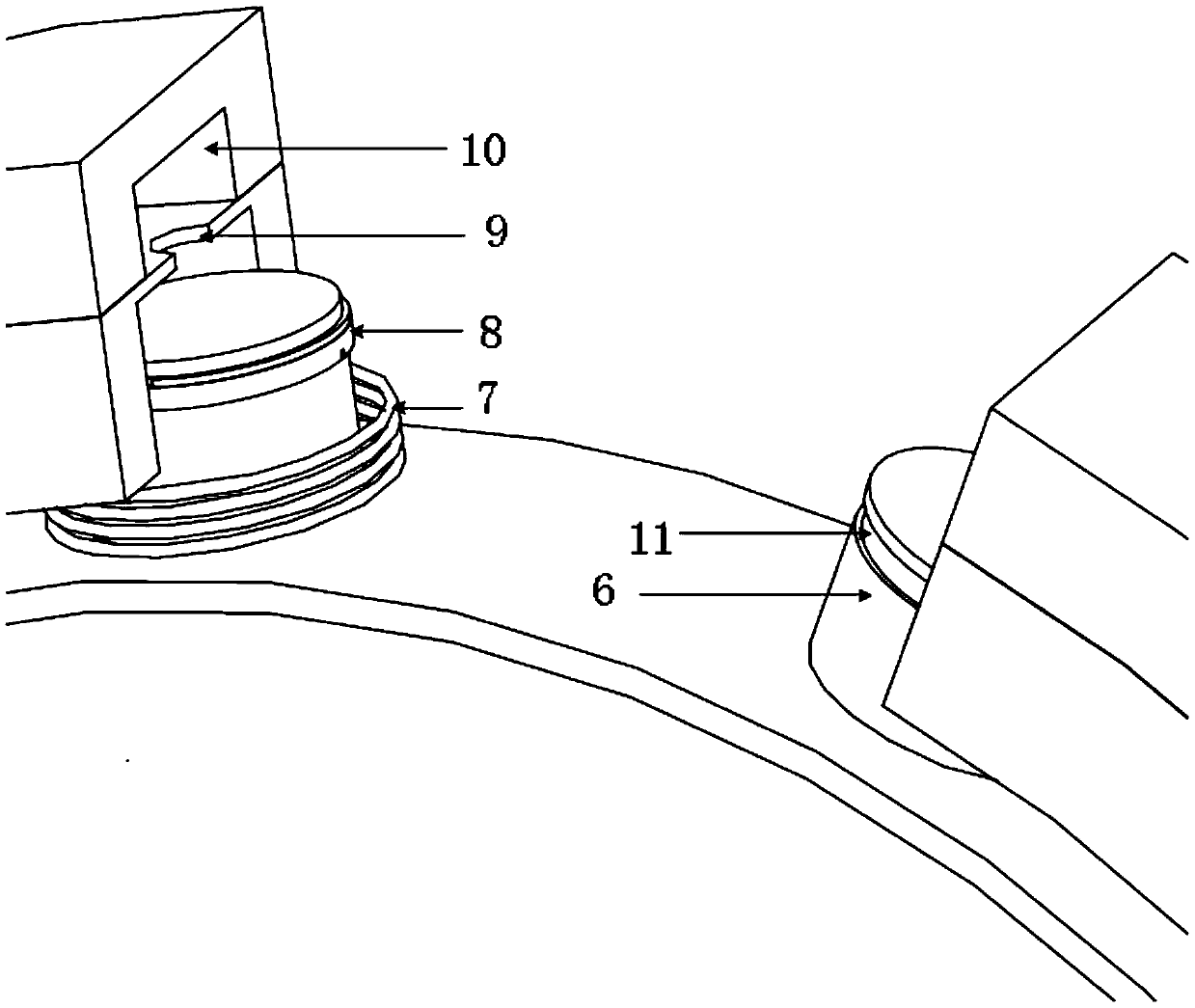

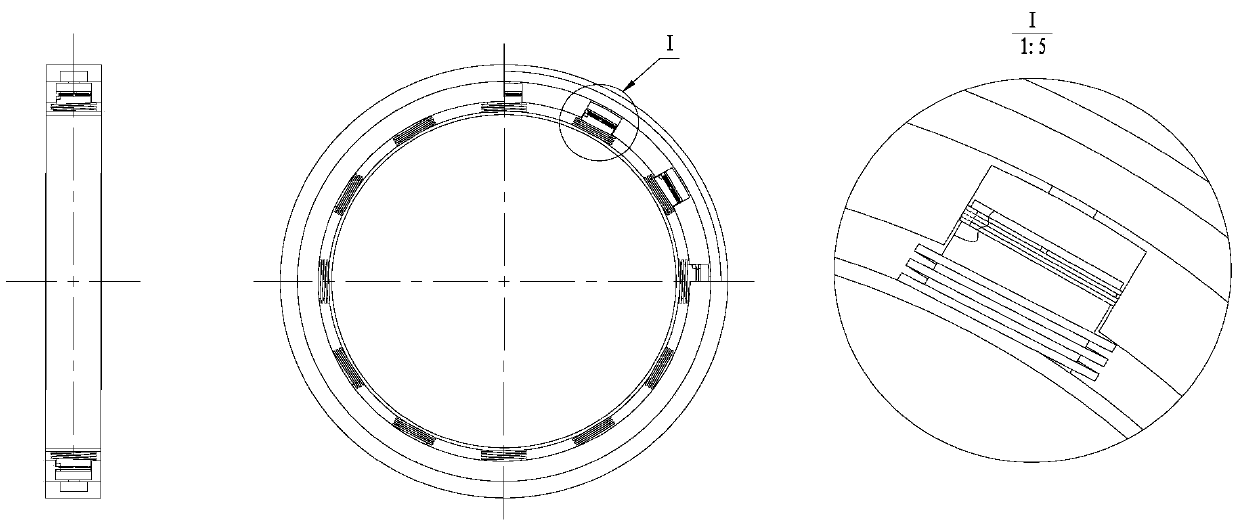

[0012] According to the principle that when the hydraulic oil passes through the damping hole at a very high speed, it can absorb a large amount of impact mechanical energy, convert the mechanical energy into heat energy, and quickly restore the rotating shaft to the normal operating state, and designs a flexible damping bearing bushing , the structure diagram of the bushing is shown in Figure 1-3 as shown in figure 1 as shown,

[0013] There is an annular hydraulic oil chamber inside the outer ring of the bushing, and several piston chambers are evenly distributed along the circumference of the bushing body. The damping hole is the connection channel between the piston chamber and the hydraulic oil in the annular hydraulic oil chamber. When flowing through the orifice at high speed, it consumes and absorbs a large amount of mechanical energy. The bush outer ring and the bush main body can be integrally formed or connected as a whole through other mechanical seals. The ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com