Thickness detection device and method based on semi-cylindrical shell capacitor

A technology of thickness detection and capacitor, which is applied in the direction of electromagnetic measuring device, electric/magnetic thickness measurement, etc., can solve the problems of shortening machine life, increasing industrial cost, secondary dust rapping, etc., and achieves low cost, convenient operation and effective detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

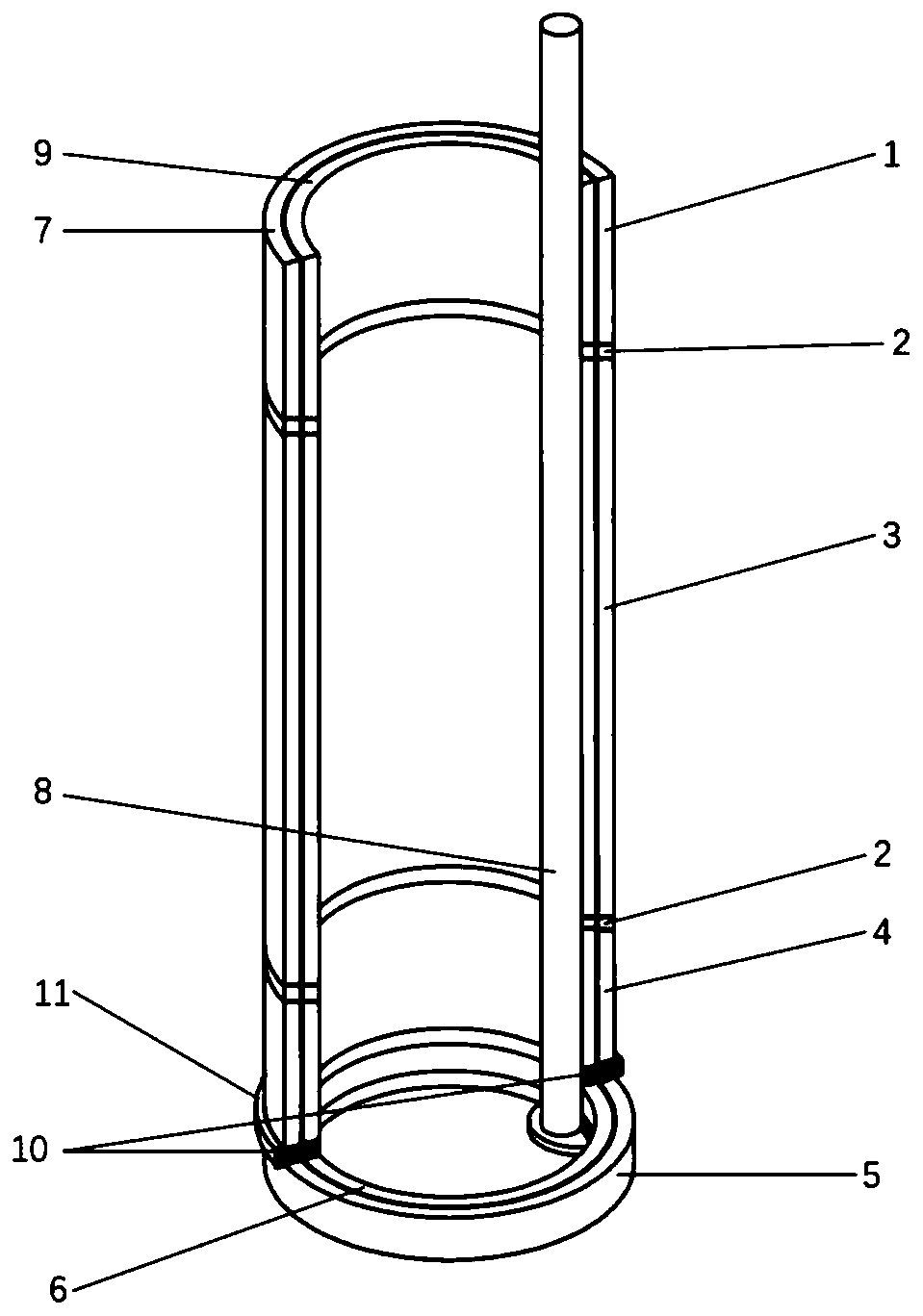

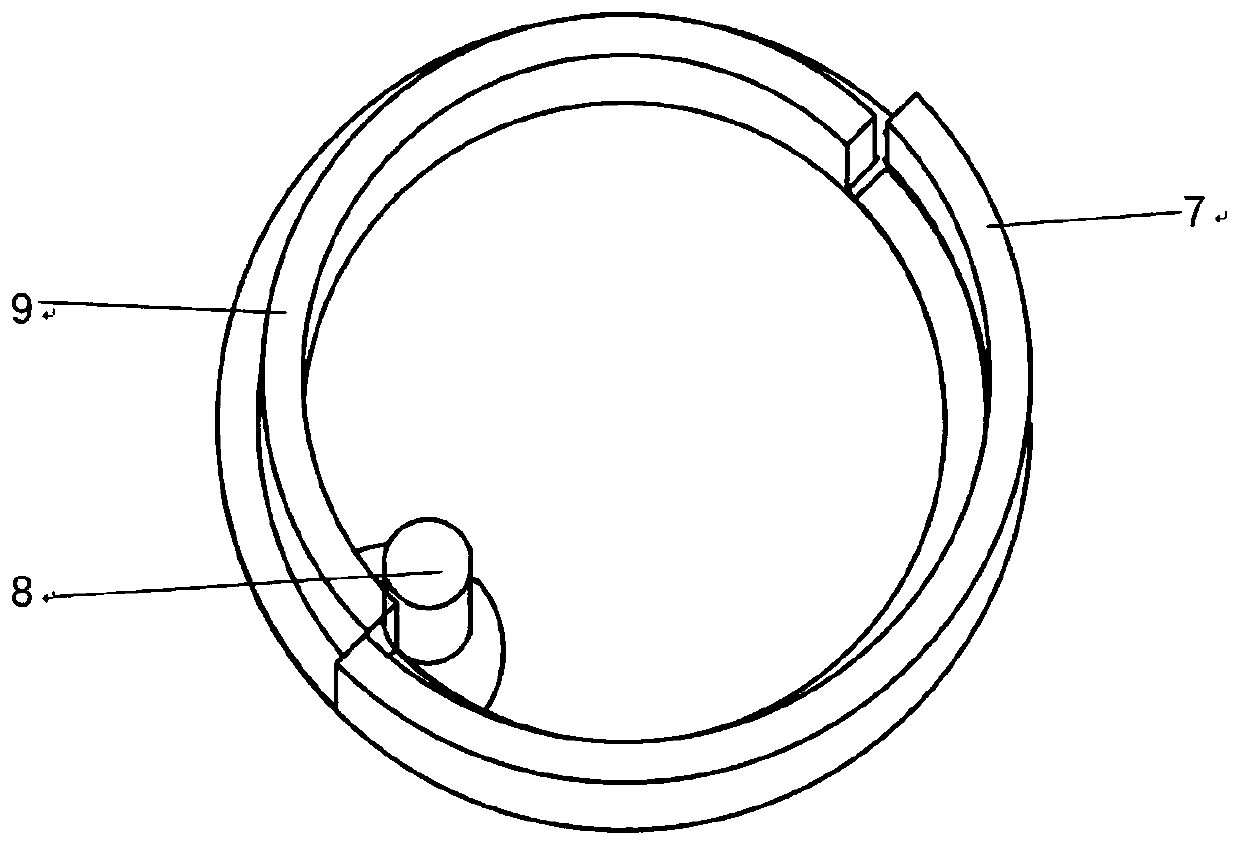

[0070] Such as Figure 4 As shown, when the object to be detected is dust, the detection method of the thickness detection device based on a semi-cylindrical shell capacitor comprises the following steps:

[0071] When not detecting, the outer pole plate 7 and the inner pole plate 9 are bonded together;

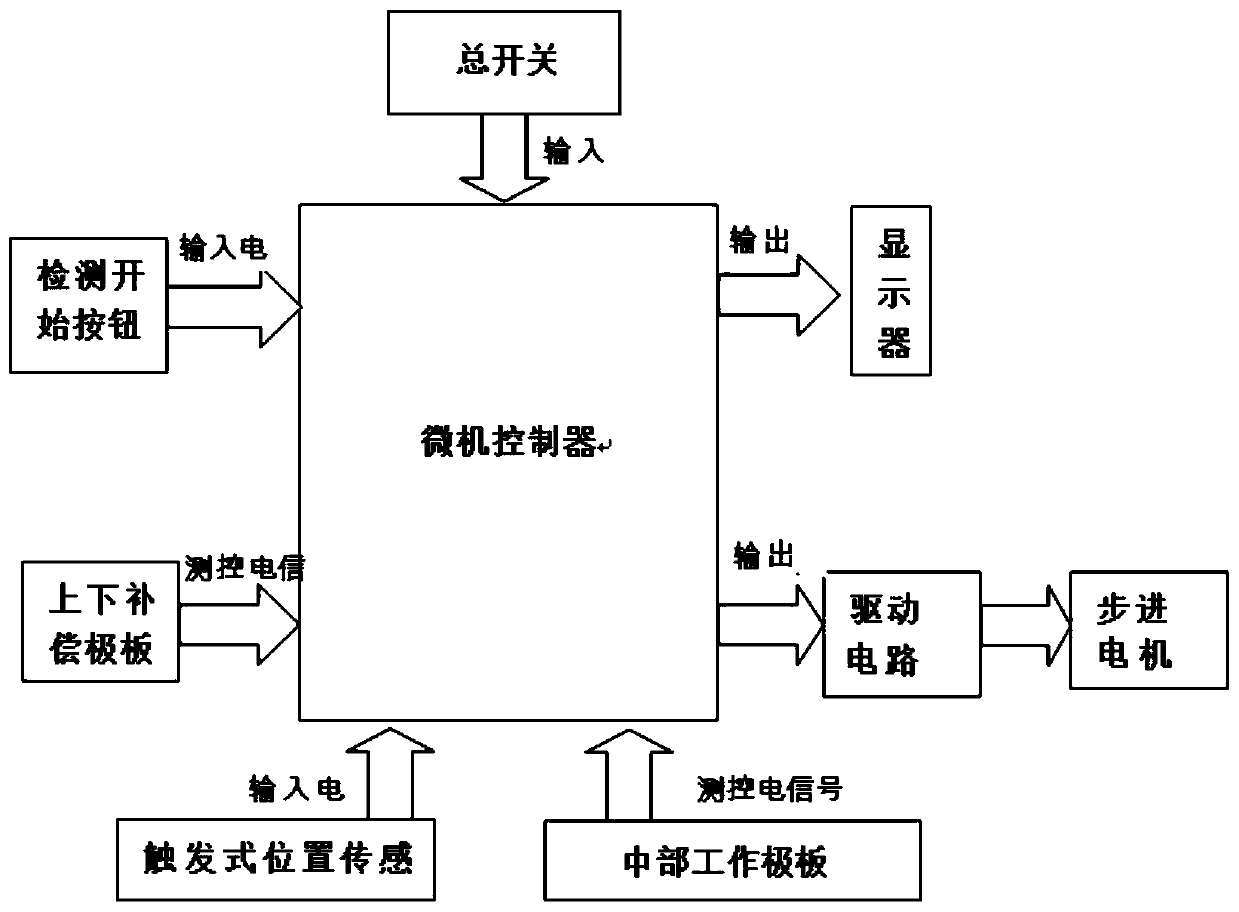

[0072] When it is desired to detect the dust deposition thickness, the stepper motor works to drive the inner pole plate 9 to rotate at a certain angle, so that the outer pole plate 7 and the inner pole plate 9 are opposite;

[0073] Obtain the dielectric constant of the dust-air mixture and the dielectric constant of the deposited dust at the current temperature through the upper compensation plate 1 and the lower compensation plate 4, as the dielectric constant reference of the middle working plate 3 for dust thickness measurement. The medium of the upper compensating plate 1 is air and dust mixture. Since the distance between the plates, the relative area and the capacita...

Embodiment 2

[0096] The object to be tested in this embodiment 2 is particulate matter. The difference between this embodiment 2 and embodiment 1 is that the thickness detection formula of the particulate matter is:

[0097]

[0098] h 颗粒物 =H 装 +l 颗粒物2 +l 颗粒物 formula sixteen

[0099] In the formula, l 颗粒物2 and l 气2 is the value to be measured, l 颗粒物2 is the height of particles in the middle plate, l 气2 is the air height in the middle plate, C 总 、C 上 、C 下 is the measured value, l 气 is the height of the upper compensating pole plate 1, the upper compensating pole, 1 is completely filled with the gas inside the device, l 颗粒物 For the height of the lower compensating pole plate 4, the lower compensating pole plate is completely filled with particles.

Embodiment 3

[0101] The object to be tested in this embodiment 2 is a liquid, and the difference between this embodiment 3 and embodiments 1 and 2 is that the thickness detection formula of the liquid is:

[0102]

[0103] h 液体 =H 装 +l 液体2 +l 液体 formula eighteen

[0104] where l 液体2 and c is the value to be measured, l 液体2 is the liquid height in the middle plate, l 液体2 is the air height inside the middle plate, C 总 、C 上 、C 下 is the measured value, l 气 is the height of the upper compensating pole plate 1, the upper compensating pole, 1 is completely filled with the gas inside the device, l 液体 For the height of the lower compensation plate 4 , the lower compensation plate is completely filled with liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com