Insulator detection mechanism and method

An insulator detection and insulator technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of national economic losses, losses, threats to the continuous and reliable operation of the power system, and achieve uniform heating and uniform cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

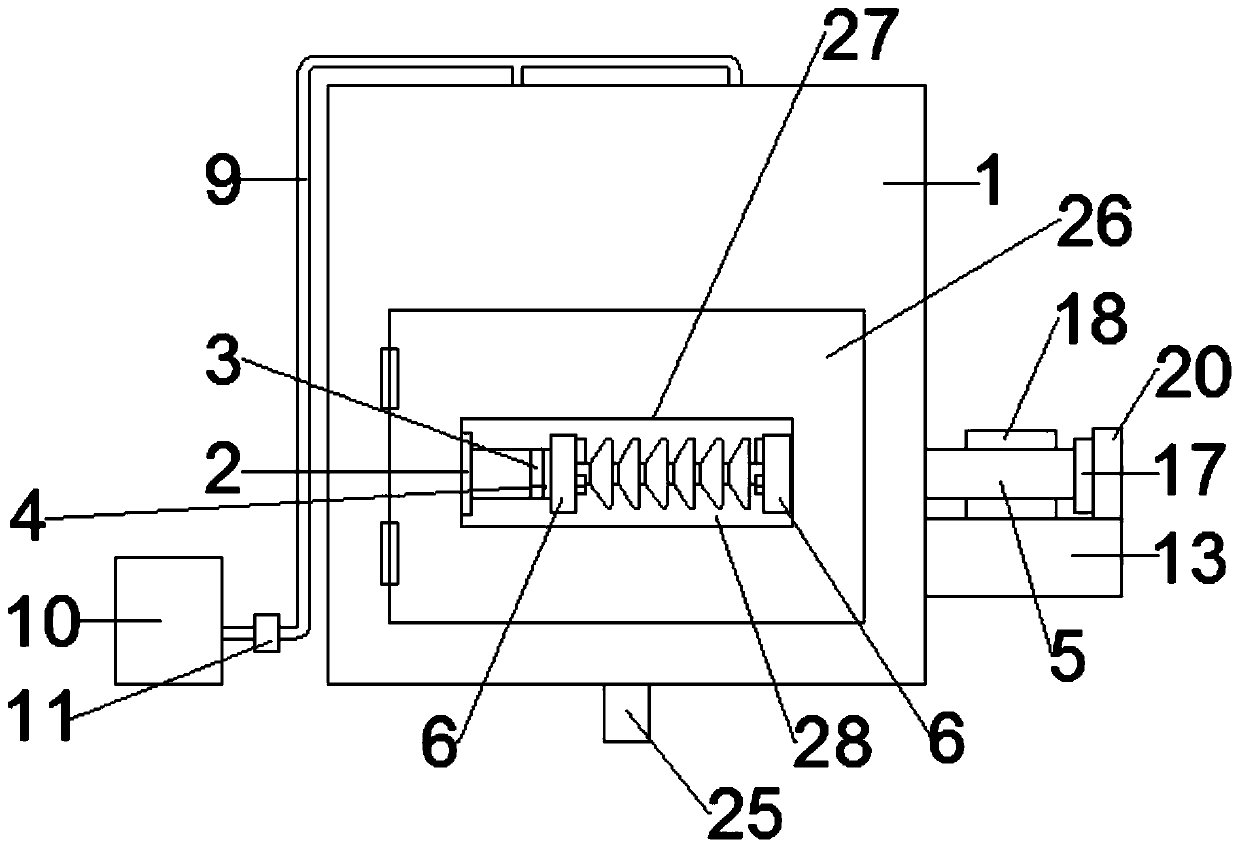

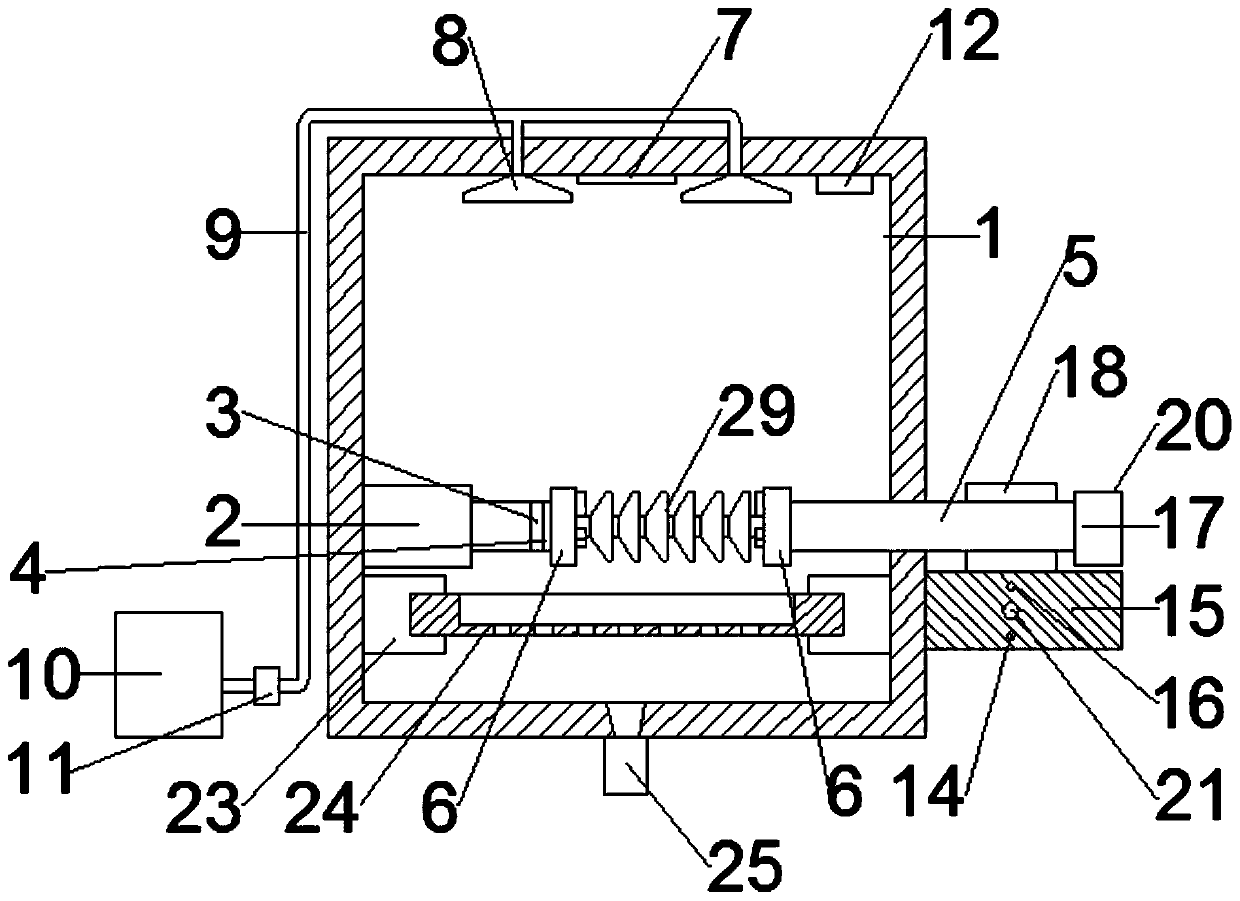

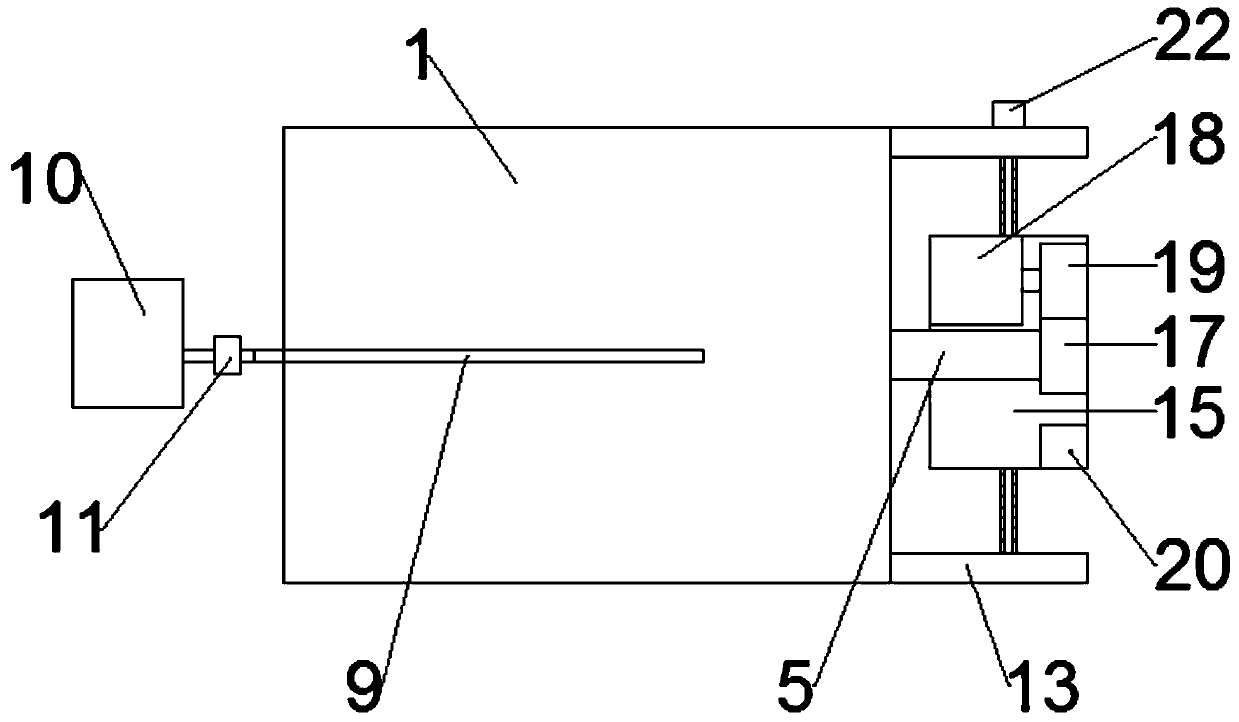

[0032] Such as Figure 1 to Figure 8 As shown, an insulator detection mechanism includes a detection box 1, a hydraulic cylinder 2 with a telescopic rod extending to the right is fixedly installed on the inner side of the left side wall of the detection box 1, and the right end of the telescopic rod of the hydraulic cylinder 2 is rotated and installed There is a fixed seat 3, the axis of rotation of the fixed seat 3 extends laterally, and the right side of the fixed seat 3 is fixedly equipped with a tension sensor 4; The axis of rotation of the shaft 5 coincides with the axis of rotation of the fixed seat 3, and the right end of the tension sensor 4 and the left end of the horizontal shaft 5 are respectively fixed with insulator fixtures; A driving device for rotating the shaft 5; a heating device is provided in the detection box 1, and a cooling device is also provided in the detection box 1.

[0033] Specifically, the insulator fixture is a three-jaw chuck 6, and the axes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com