Corrosion resistance evaluation method for low alloy structural steel

An evaluation method and technology for low-alloy steel, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., which can solve the problems of inconvenient operation and long experimental period, and achieve the effect of shortening the experimental period and simple experimental process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Table 1 shows the weight percentages of the chemical components of the low-alloy steels in the examples using the method for evaluating the corrosion resistance of low-alloy structural steels according to the present invention. And according to the low-alloy steel corrosion resistance index I calculation formula, the corrosion resistance indices of the eight examples are obtained, as shown in Table 2.

[0025] The chemical composition of eight kinds of embodiments of table 1

[0026]

[0027] Table 2 Atmospheric corrosion resistance index I value of eight test steels

[0028]

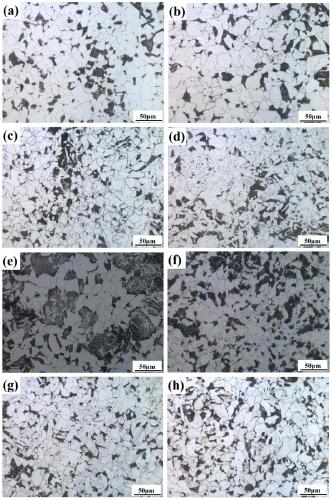

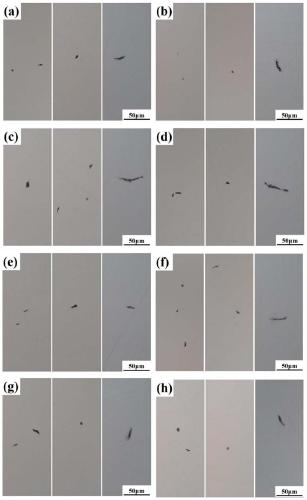

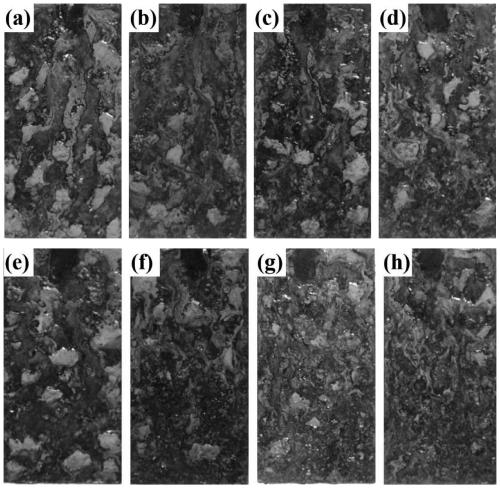

[0029] Cut the samples of the eight examples into 10mm×10mm×3mm sheet-like samples along the normal direction, grind them step by step with No. 60-2000 water sandpaper, then mechanically polish the samples, and then clean them with deionized water and acetone , to remove surface oil. Afterwards, according to the "GB / T 10561-2005 Determination of Non-metallic Inclusion Content in Steel Sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com