Porous graphene as well as preparation method and application thereof

A technology of porous graphene and graphene, which is applied in the field of preparation of porous graphene materials, can solve the problems of unsatisfactory industrial application, cost and complicated experimental process, etc., and achieve remarkable opening effect, wide application range and simple experimental process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Add 10ml of 80mM ferric nitrate aqueous solution to 200ml of 0.05%wt / wt GO aqueous solution, stir at room temperature for 24h, then centrifuge, and dry GO at 60°C after compounding iron ions.

[0034] 2) Treat the dried sample at 900° C. for 30 minutes under a protective atmosphere. The sample obtained after cooling was soaked in dilute hydrochloric acid, washed with deionized water, and dried at 80° C. to obtain the final porous graphene material.

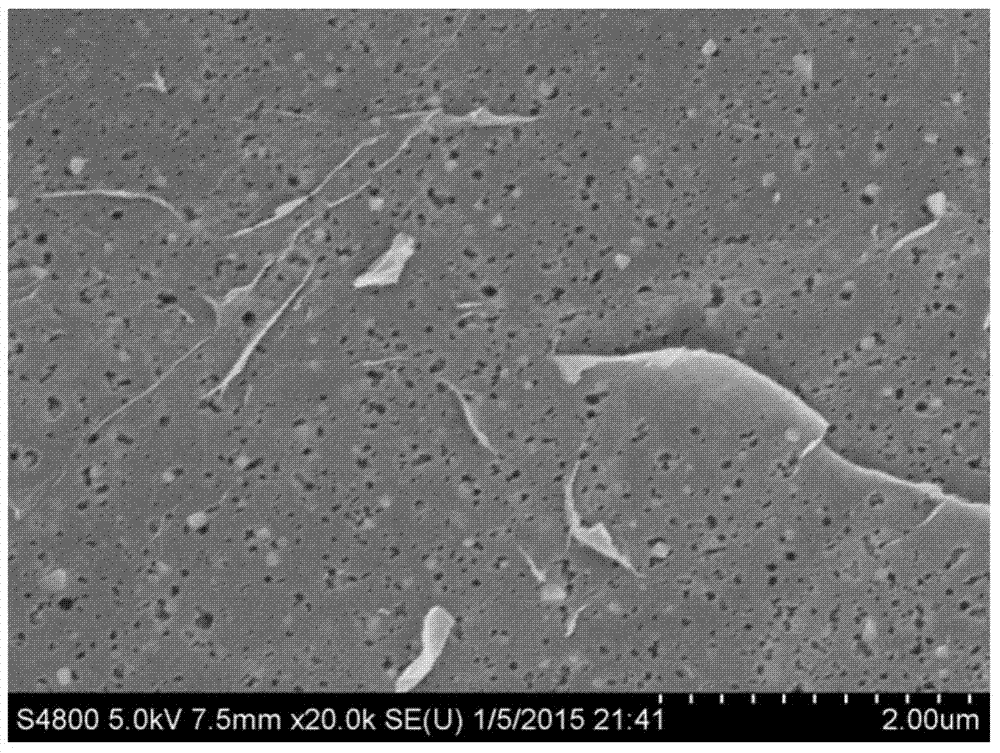

[0035] In this embodiment, due to the large amount of metal ions used in opening the pores, many pores are superimposed to form continuous pores, and there are also many small pores distributed, and the pore size distribution is not very uniform. The pores are evenly distributed on the graphene without enrichment in certain regions. Its pore size (diameter) distribution ranges from 50 to 400nm, mainly concentrated at 150nm, and the number of pores is 36 / μm 2 .

Embodiment 2

[0037] 1) Add 1ml of 80mM ferric nitrate aqueous solution to 200ml of 0.05%wt / wt GO aqueous solution, stir at room temperature for 24h, then centrifuge, and dry GO at 60°C after compounding iron ions.

[0038]2) Treat the dried sample at 900° C. for 30 minutes under a protective atmosphere. The sample obtained after cooling was soaked in dilute hydrochloric acid, washed with deionized water, and dried at 80° C. to obtain the final porous graphene material.

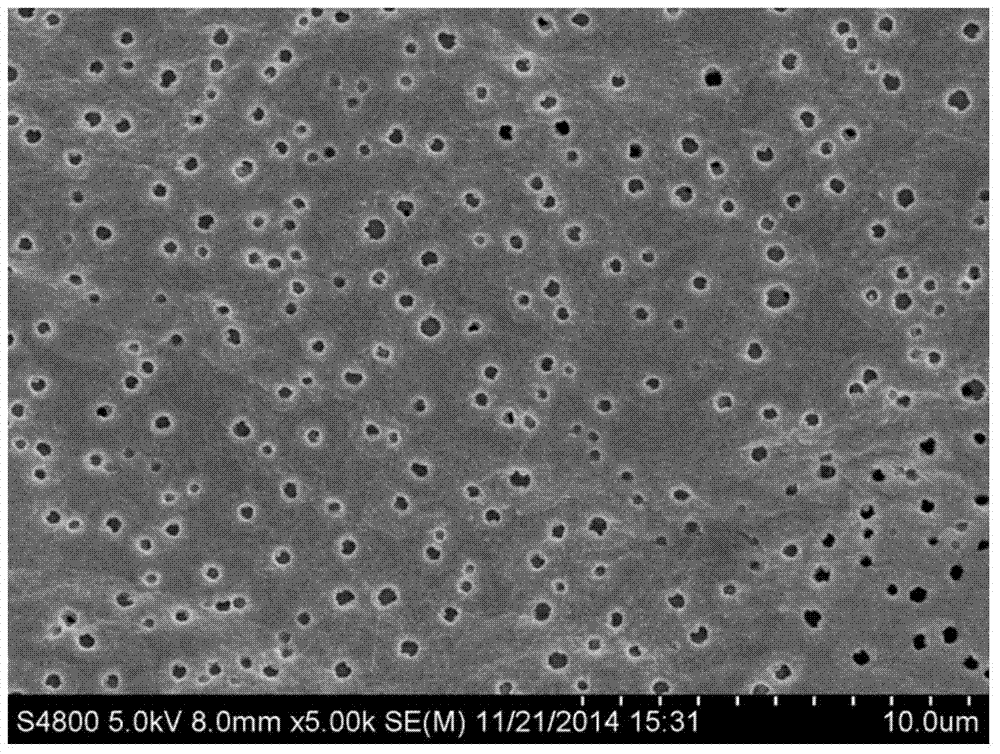

[0039] In this embodiment, since the amount of metal ions used in opening the pores is more appropriate, the pores are not superimposed on each other, and are basically isolated pores. In addition, the uniformity of the pore size distribution is better. The pores are evenly distributed on the graphene without enrichment in certain regions. Its pore size (diameter) distribution ranges from 20 to 200nm, mainly concentrated at 80nm, and the number of pores is 66 / μm 2 .

Embodiment 3

[0041] 1) Add 0.1ml of 80mM ferric nitrate aqueous solution to 200ml of 0.05% wt / wt GO aqueous solution, stir at room temperature for 24h, then centrifuge, and dry GO at 60°C after compounding iron ions.

[0042] 2) Treat the dried sample at 900° C. for 30 minutes under a protective atmosphere. The sample obtained after cooling was soaked in dilute hydrochloric acid, washed with deionized water, and dried at 80° C. to obtain the final porous graphene material.

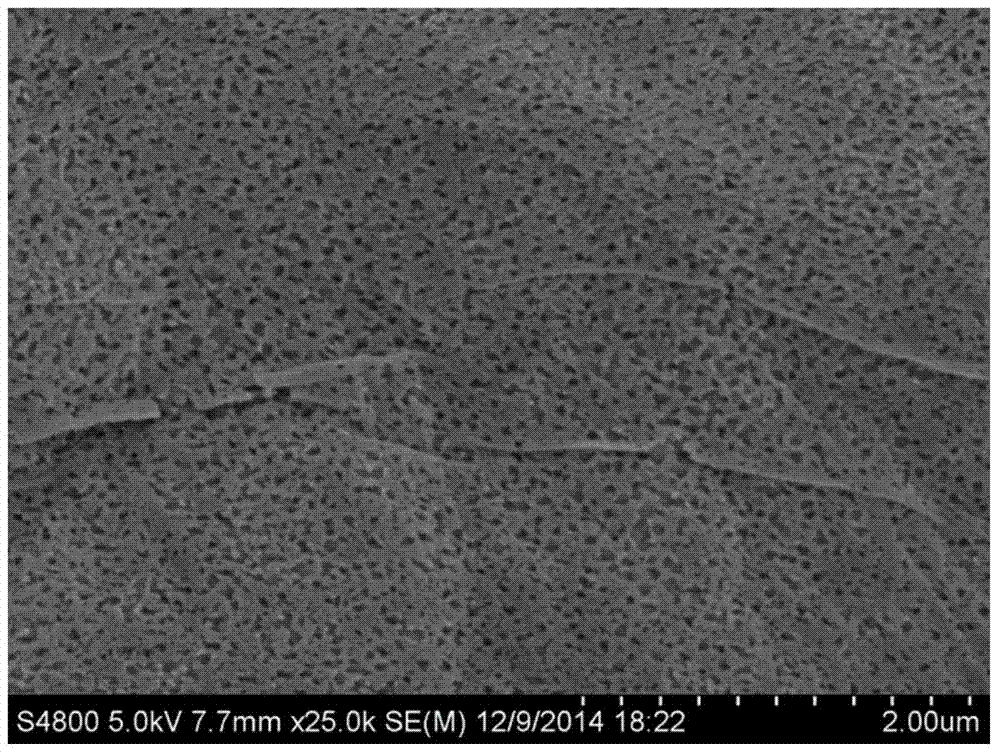

[0043] In this embodiment, since the amount of metal ions used to open the pores is small, the pores do not overlap with each other and exist in isolation; the uniformity of the pore size distribution is better. In addition, compared to Example 2, the number of holes is much reduced. Pores are regionally enriched in graphene. Its pore size (diameter) distribution ranges from 150 to 200nm, mainly concentrated at 80nm, and the number of pores is 7.5 / μm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com