Lens holder and coupling positioning device for multi-channel cob packaging

A positioning device, multi-channel technology, applied in the coupling of optical waveguides, instruments, optics, etc., can solve the problems of low coupling accuracy and unstable clamping of fixtures, achieve high coupling accuracy, improve product quality, and clamp stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0029] The invention provides a lens clamping and coupling positioning device for multi-channel COB packaging aiming at the problems of low coupling precision and unstable clamping of existing clamping and coupling positioning devices.

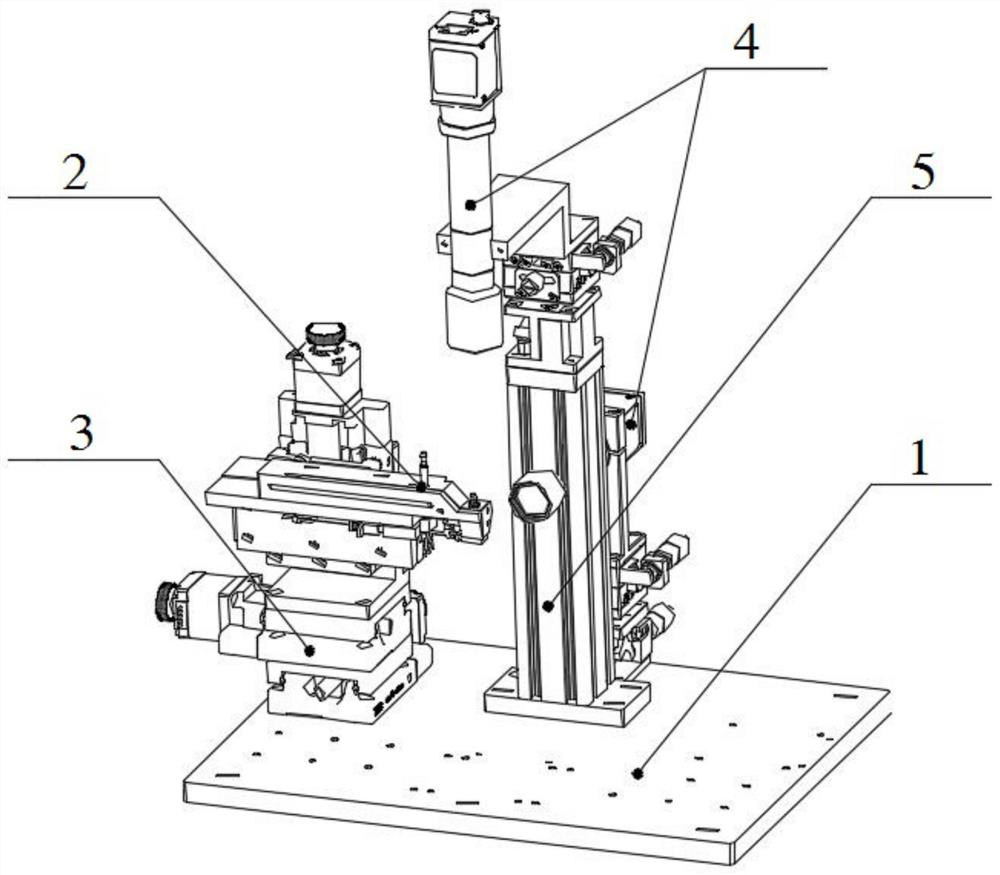

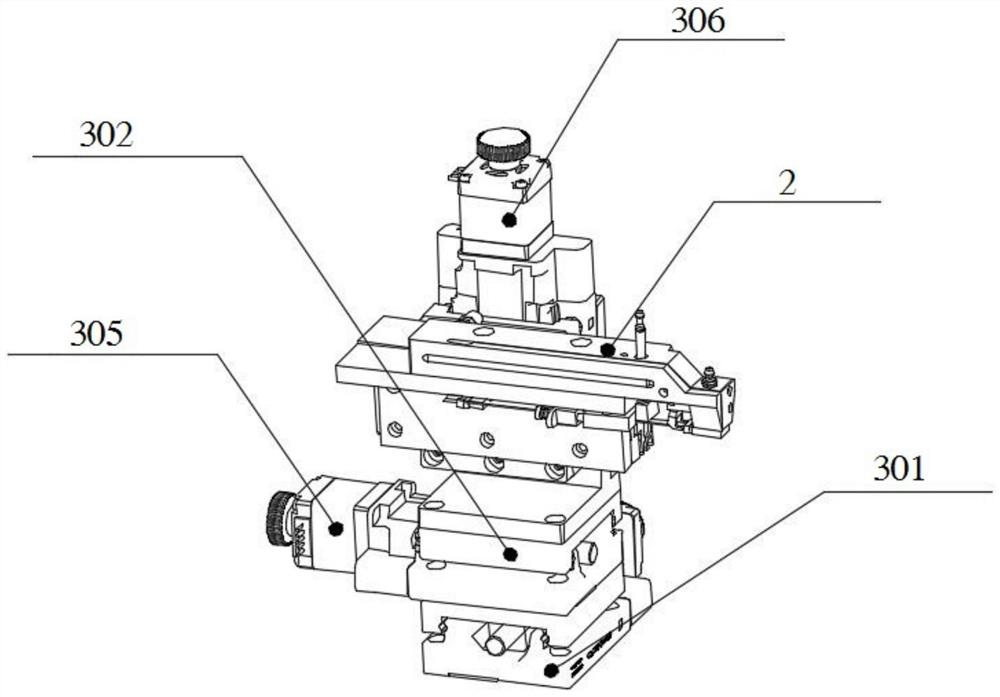

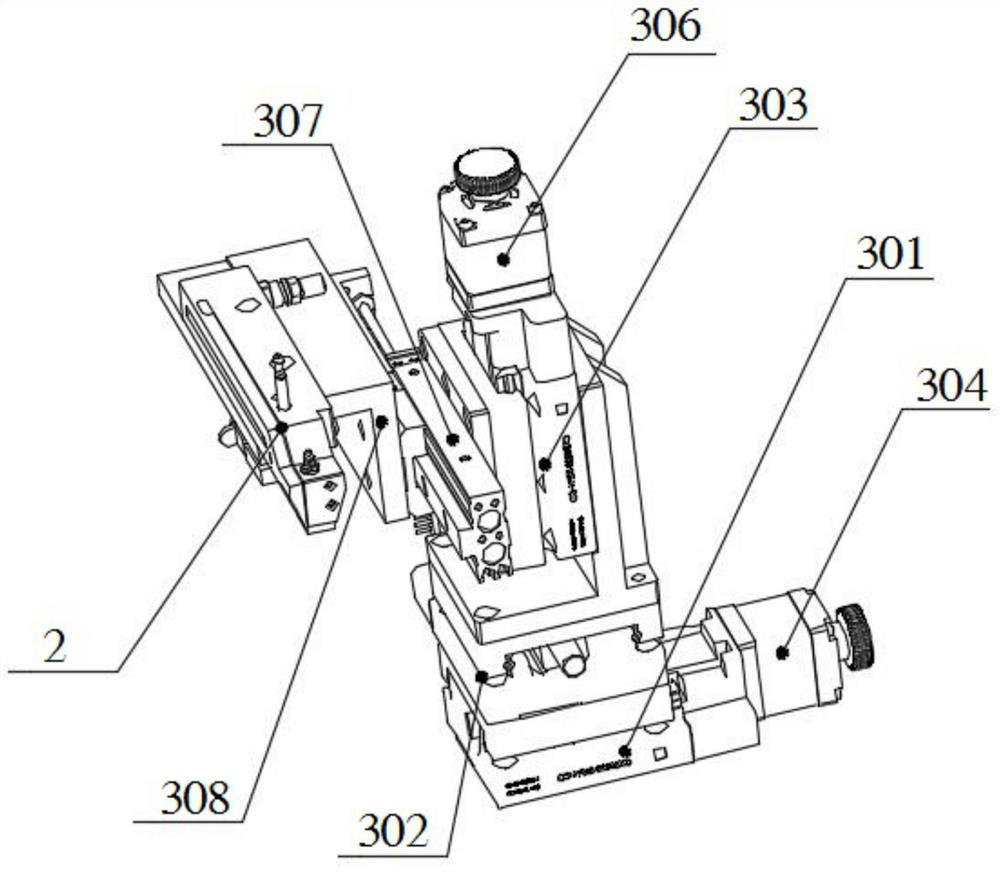

[0030] like Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a lens clamping and coupling positioning device for multi-channel COB packaging, including: a mounting plate 1, a lens clamp 2, a three-dimensional motion platform 3, a monitoring device 4 and a support column 5; The three-dimensional motion platform 3 includes an X-direction slide table 301, a Y-direction slide table 302 and a Z-direction slide table 303. , the Y-direction motor 305 and the Z-direction motor 306 drive, the X-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com