Motor winding enameled wire spontaneous heating curing method and winding motor adopting method

A technology of motor winding and curing method, which is applied to windings, electric components, manufacturing of motor generators, etc., can solve the problems of inflexible and convenient winding thermal curing operation, occupying plant space and energy consumption, and damage to motor windings, and achieves thermal curing operation. Flexible and convenient, improve the normal use of work, take up less space in the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

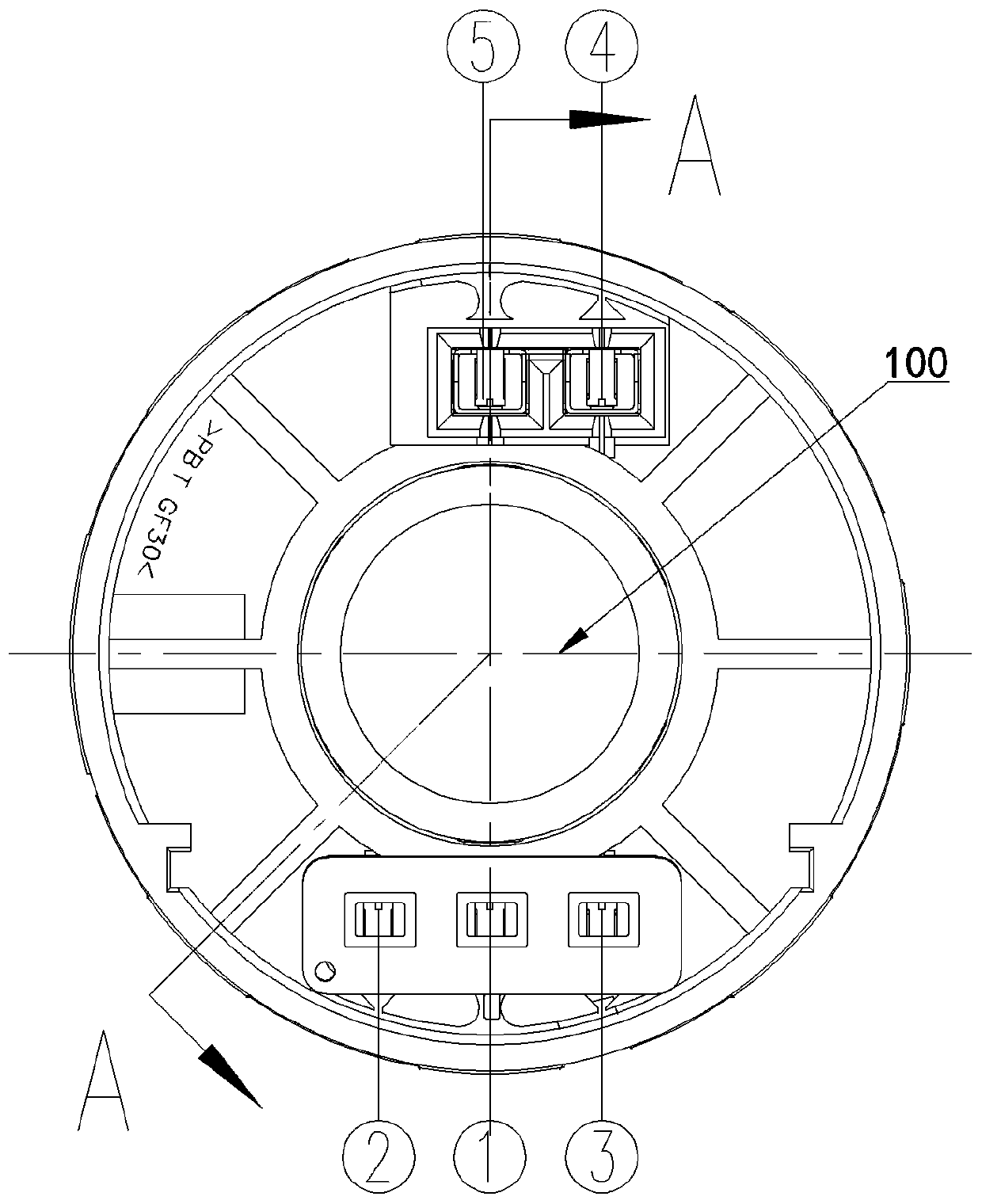

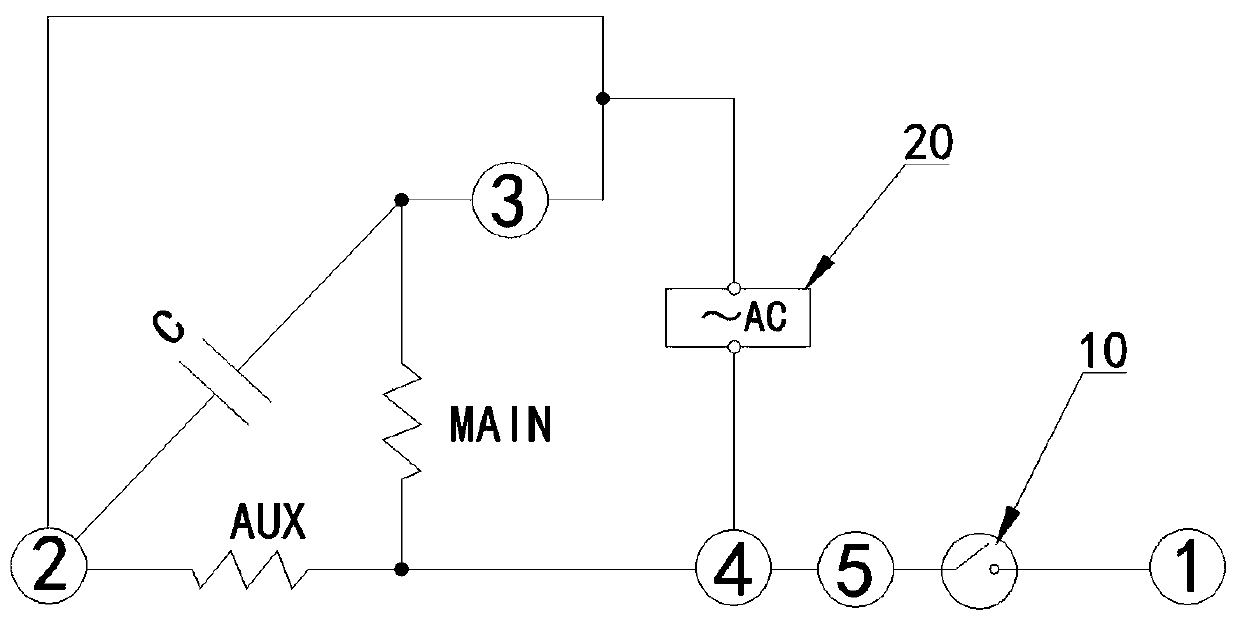

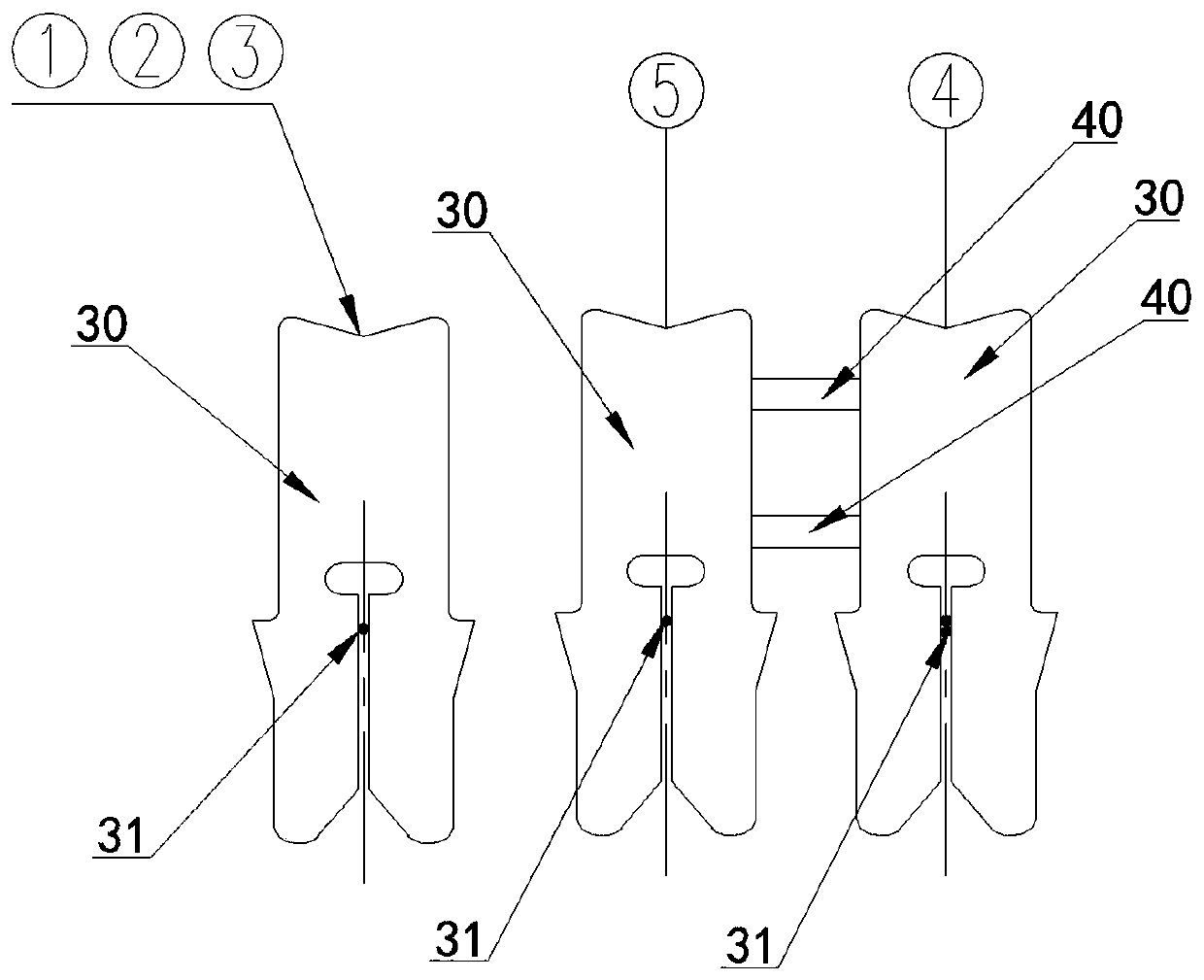

[0026] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 In the shown embodiment, a method for self-heating and curing of motor winding enameled wire, including main phase winding wire A head 3 connected to each winding wire head of the motor, auxiliary phase winding wire A head 2, main phase winding wire B head, auxiliary phase winding wire Winding wire B head, thermal protector lead wire A head 1 and thermal protector lead wire B head 5 are characterized in that the main and auxiliary winding B head parallel wires formed by connecting the main phase winding wire B head and the auxiliary phase winding wire B head in parallel After 4, connect the A head of the main phase winding wire and the A head of the auxiliary phase winding wire in parallel to form a parallel wire of the A head of the main and auxiliary winding 4, and then connect the lead wire B of the thermal protector with the A head of the main and auxiliary winding Car...

Embodiment 2

[0028] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 In the shown embodiment, a self-heating cured winding motor includes a stator core 60, a thermal protector lead wire A head 1, a thermal protector lead wire B head 5, a stator coil 50, and a wire head connected to each winding wire head of the motor stator coil. Main phase winding wire A head 3, auxiliary phase winding wire A head 2, main phase winding wire B head and auxiliary phase winding wire B head, and the main phase winding wire B head and auxiliary phase winding wire B head are connected in parallel to form the technology of embodiment 1 After the main and auxiliary winding B head parallel wires 4 described in the plan, the main and auxiliary winding B head parallel wires 4 and the thermal protector lead wire B head 5 are set at the adjacent position on the same side of the motor stator coil end, and the main phase winding wires A head 3, A head 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com