Aftertreatment method used for inducer machining

A technology of an inducer and a processing box, which is applied in the directions of cleaning methods using liquids, dry goods processing, cleaning methods and utensils, etc., can solve the problems of increased production costs, large energy loss, and large workload, and achieves automatic operation, Guaranteed accuracy, practical operation and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

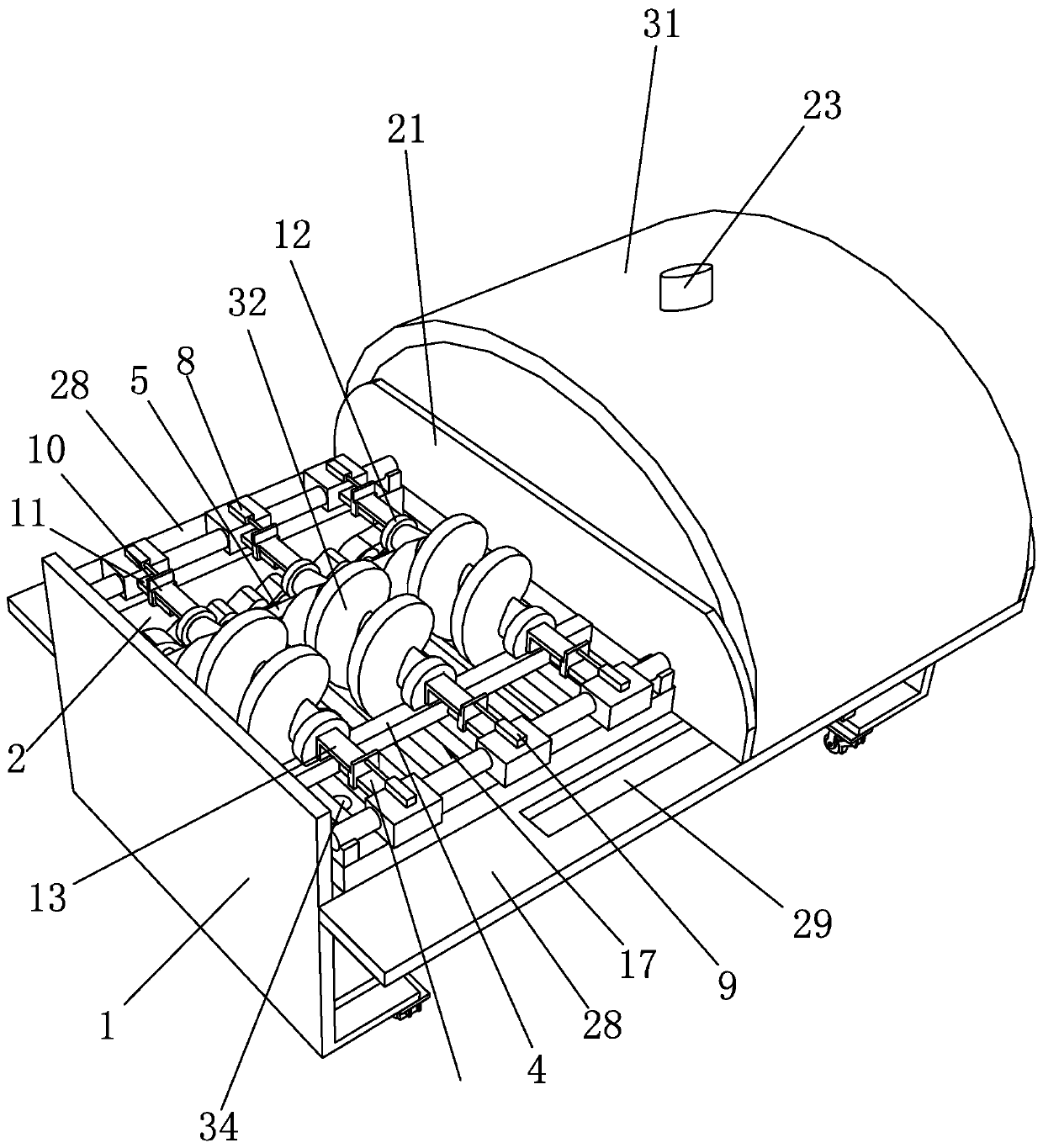

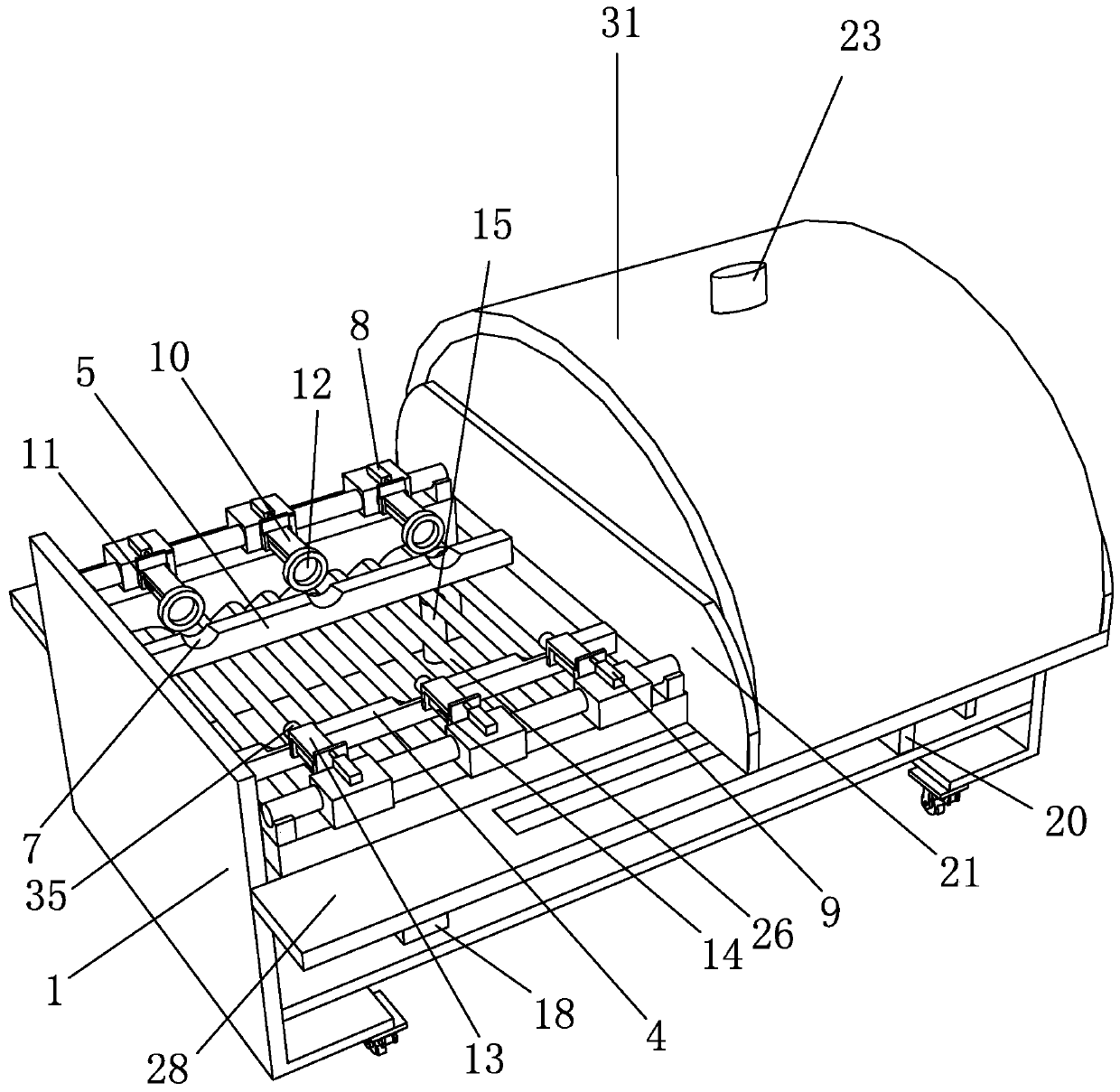

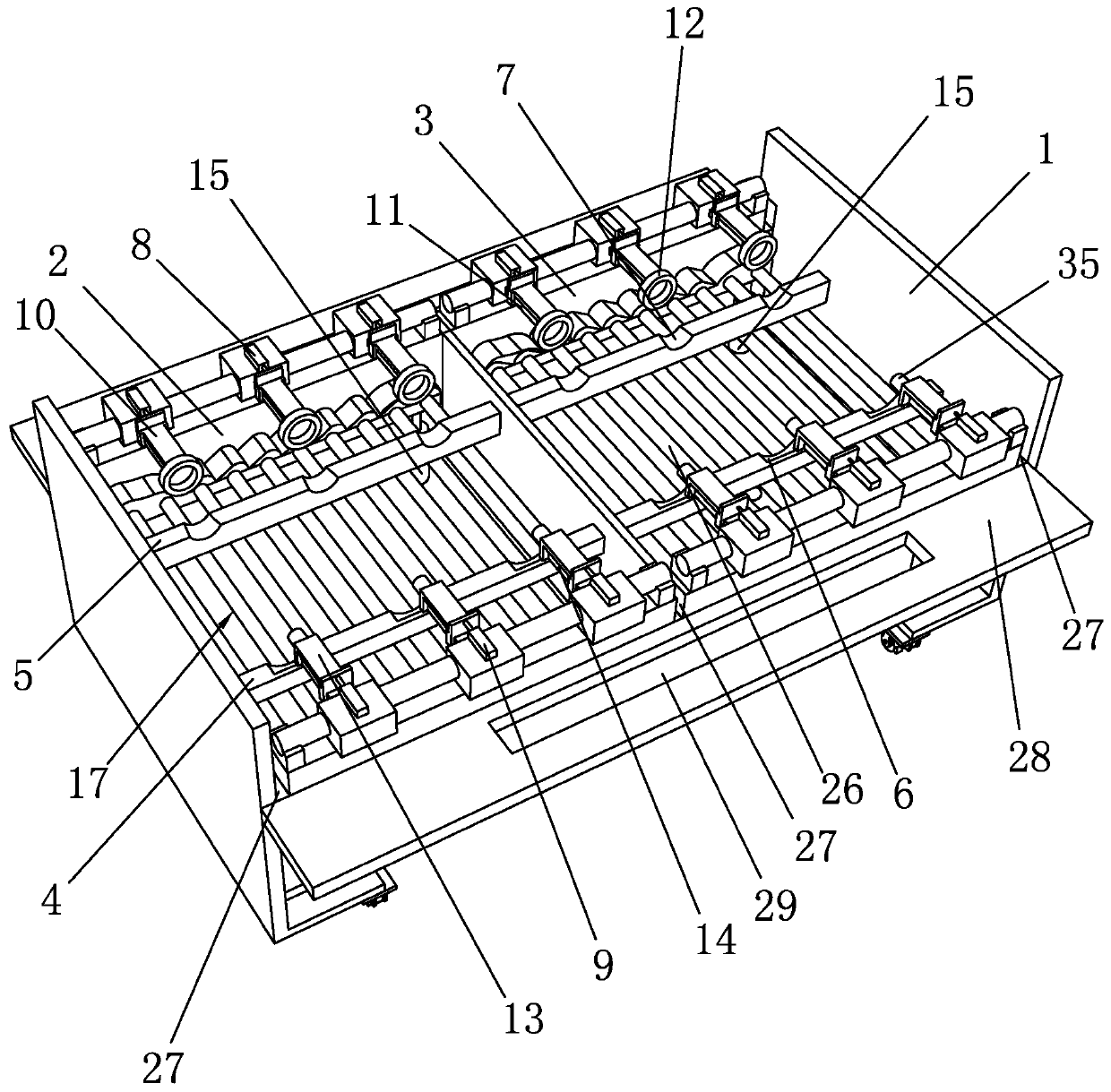

[0032] like Figure 1 to Figure 7 Shown, be a kind of post-processing method for induction wheel processing of the present invention, comprise the steps:

[0033] a, the placement of the inducer 32:

[0034] 1) First place the induction wheel 32 on the placement platform 16 of the left cavity 2 of the processing box 1, and the end of the induction wheel 32 connected to the shaft is snapped into the front groove 6 on the front limit plate 4 of the placement platform 16, and induces The other end of the wheel 32 is clamped in the corresponding rear groove 7 on the rear limiting plate 5 of the placement table 16 until the clamping placement of all the induction wheels 32 in the left cavity 2 is completed; through the front groove 6 and the rear groove 7. Realize the preliminary clamping and positioning of the induction wheel 32 to ensure the accuracy of the actual material position, thereby facilitating the precise positioning between the subsequent ferrule 12, the insertion rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com