A device for automatically opening the bottom of a copper chafing dish

A hot pot and automatic technology, applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of personal injury, cumbersome working steps, time-consuming and laborious, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

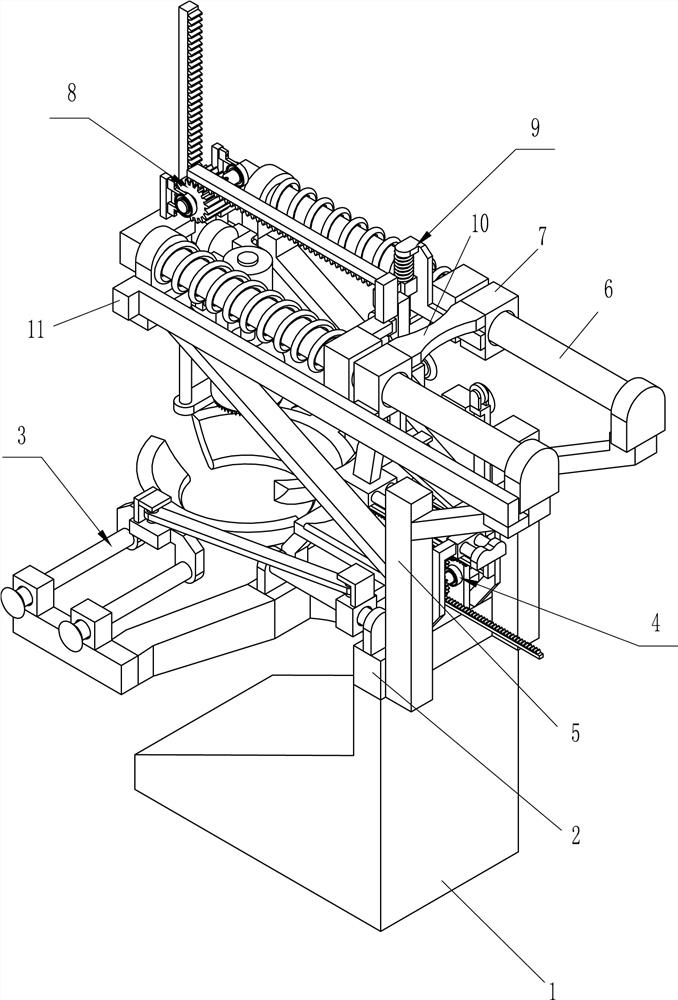

[0026] A device for automatically opening the bottom of a copper chafing dish, such as Figure 1-2 As shown, it includes a chassis 1, a mounting frame 2, an opening and closing device 3, a pushing device 4, a support rod 5, a first guide rail 6, a first guide sleeve 7, a drilling device 8, a contact device 9, a connecting block 10 and Electric slide rail 11, the opening and closing device 3 is used to place the hot pot pot and is triggered to open and close by linkage, the pushing device 4 is used to push the hot pot pot to be processed and link the opening and closing device 3, and the drilling device 8 is used to align the opening and closing device The chafing dish basin on 3 is drilled, the contact device 9 is used to control the movement stroke of the pushing device 4 and the drilling device 8, and the electric slide rail 11 is used to provide the stroke power of the drilling device 8 and link the contact device 9, specifically:

[0027] The upper side of the base frame 1...

Embodiment 2

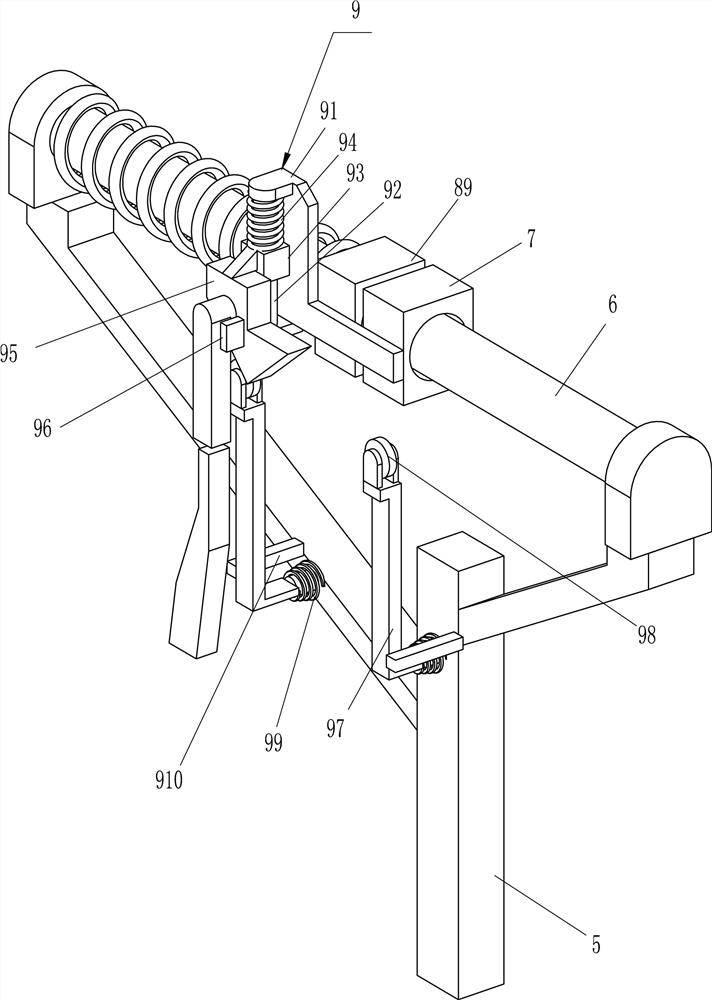

[0030] On the basis of Example 1, such as Figure 3-5 Shown:

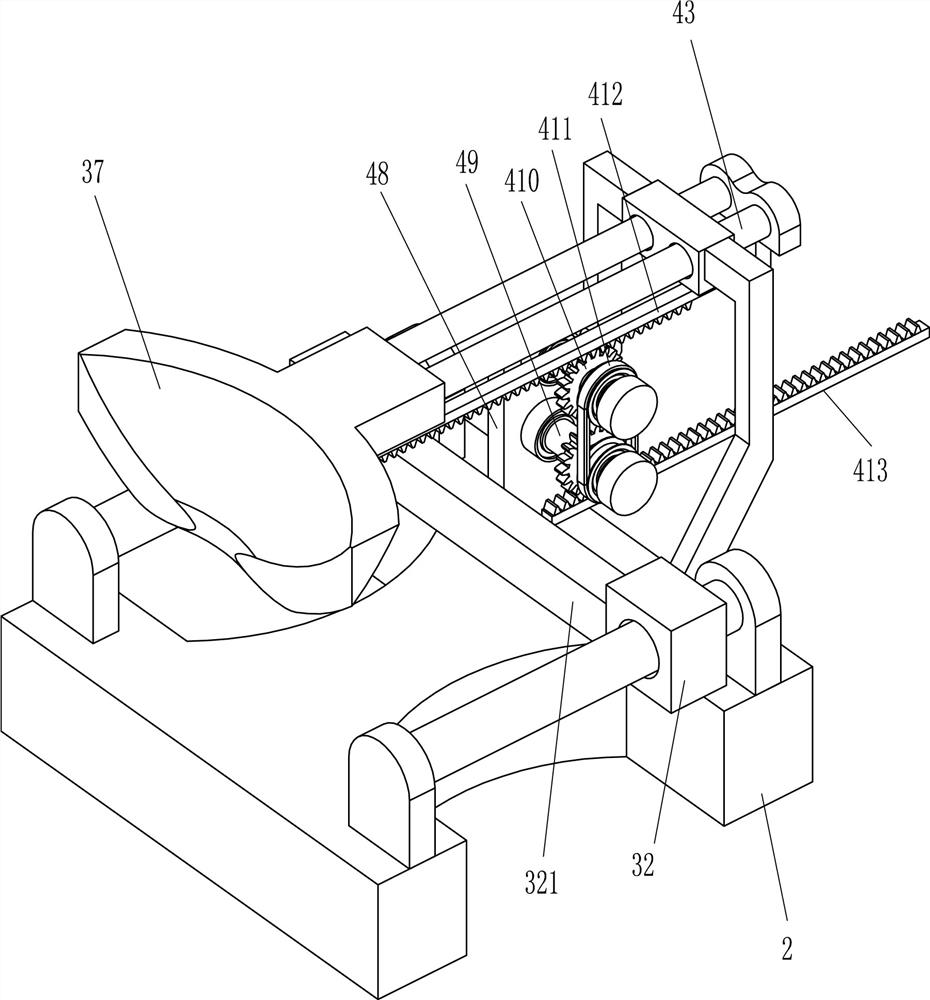

[0031] The opening and closing device 3 includes a second guide rail 31, a second guide sleeve 32, a connecting rod 321, a third guide sleeve 33, a third guide rail 34, a connecting seat 35, a push rod 36 and a placement basin 37, and the placement basin 37 is The semicircular placement container cooperates with each other between placement basins 37, specifically:

[0032] Two sets of second guide rails 31 are arranged on the mounting frame 2, and second guide sleeves 32 are slidably connected on the second guide rails 31, and connecting rods 321 are connected between the second guide sleeves 32, and the connecting rods 321 is connected with the pushing device 4, and the mounting bracket 2 is symmetrically connected with a third guide sleeve 33 on the side away from the support rod 5, and the third guide sleeve 33 is slidably connected with a third guide rail 34 inside, and the third guide sleeve 33 is slidably c...

Embodiment 3

[0048] On the basis of Example 2, such as image 3 As shown, also includes a curved plate 407, specifically:

[0049] An arc-shaped plate 407 is connected to the upper side of the placement plate 46 .

[0050] When the above-mentioned embodiment is in operation, the arc-shaped plate 407 can place the chafing dish pot stably and avoid toppling over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com