Non-contact limiting device

A limit device and non-contact technology, which is applied in the direction of railway signals and safety, can solve problems such as potential safety hazards, failure of stroke control, and impact on production efficiency, so as to improve reliability and safety, solve potential safety hazards, and eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the examples.

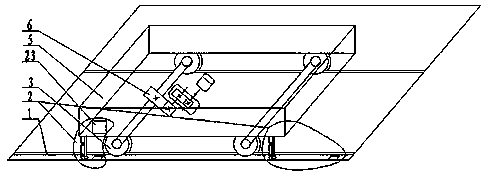

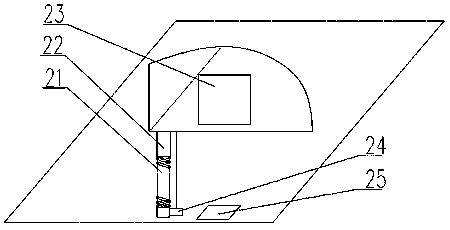

[0036] The invention discloses a non-contact limit device, which is arranged on the front and rear ends of each traveling mechanism, including a mechanical connection mechanism and an electrical detection system, wherein the mechanical connection mechanism includes a fixed bracket 21 arranged at the lower part of the traveling mechanism, installed on The elastic deformation mechanism 22 on the fixed support 21; the electrical detection system includes an electric control box 23 installed on the outer surface of the running mechanism, a detection switch 24 installed on the elastic deformation mechanism 22, and a control panel fixed on the independent working area of each running mechanism. The feedback board 25 on the ground at both ends, the detection switch 24 is matched with the feedback board 25 correspondingly;

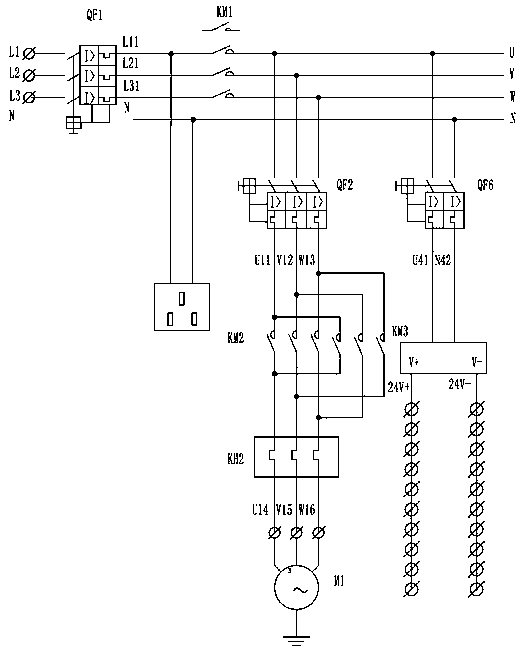

[0037] The electric control box 23 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com