Material storage mechanism of suction machine

A technology of suction machine and material storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

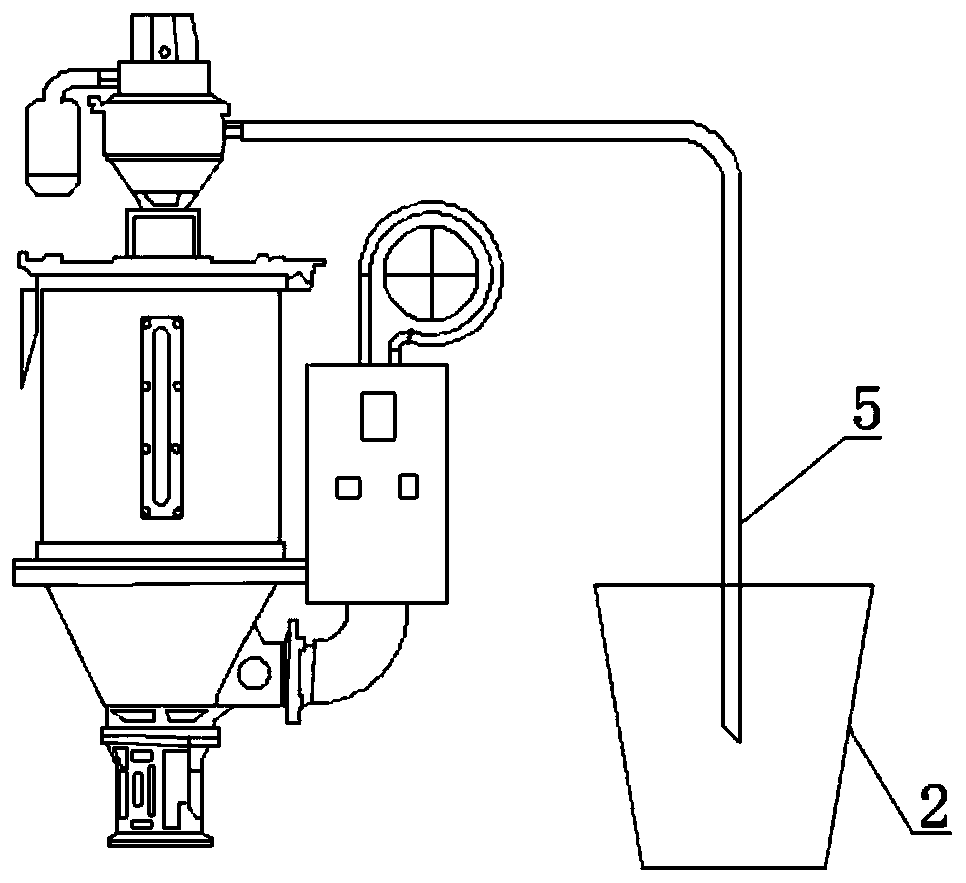

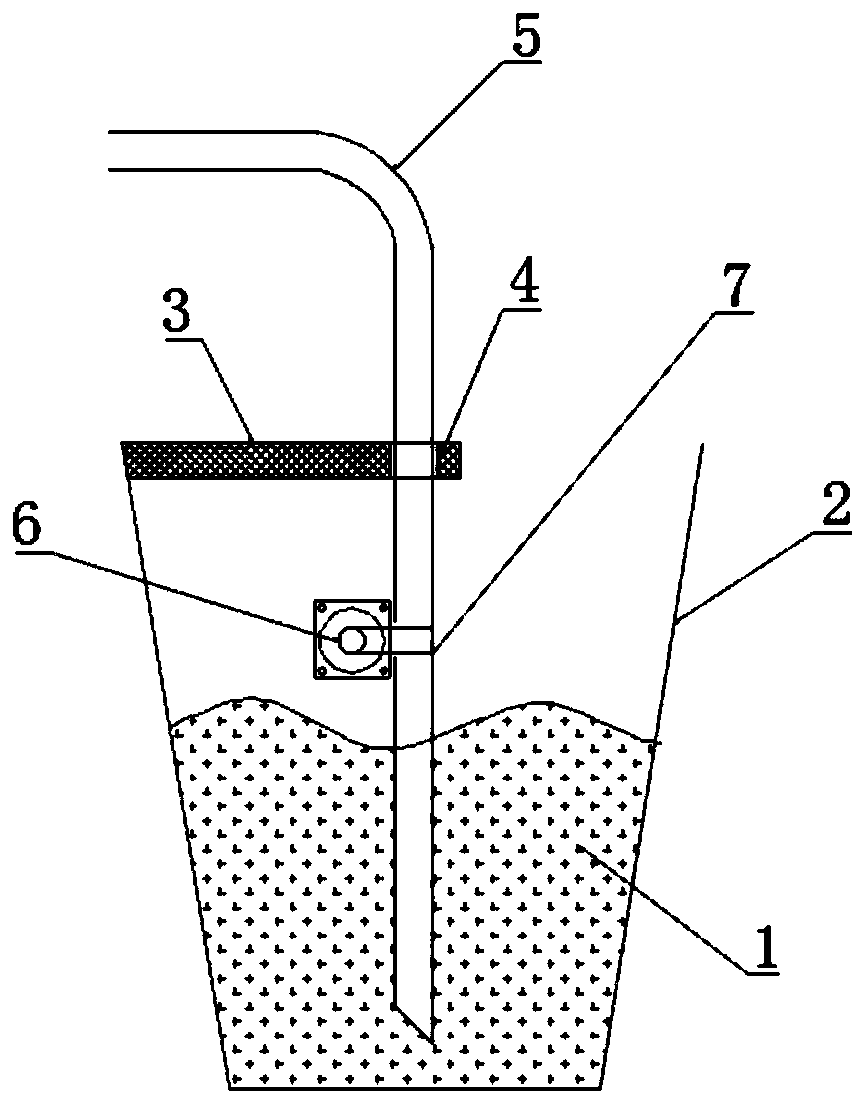

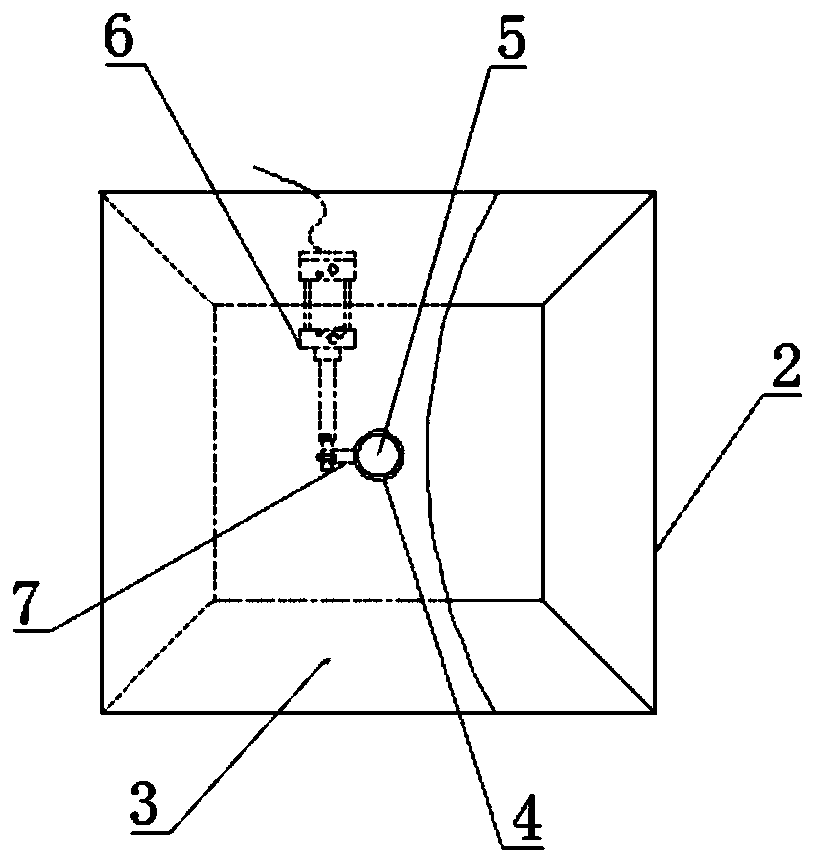

[0023] Such as figure 2 As shown, a material storage mechanism of a suction machine includes a material storage body 2, a fixed plate 3, a push-pull mechanism 6,

[0024] The side wall of the storage body 2 is inclined inwardly from top to bottom, and is in the shape of a square box or a tapered barrel. The fixing plate 3 is installed on the top of the storage body 2, and a feeding gap is left; the top of the storage body 2 The fixing plate 3 in the center is provided with a through hole, and a clamping block 4 is arranged in the through hole, and the clamping block 4 clamps the suction pipe 5 to limit its vertical movement.

[0025] The push-pull mechanism 6 is arranged inside the cavity of the material storage body 2, higher than the top of the pellet 1, the fixed part of the push-pull mechanism 6 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com