A kind of preparation method of oxygen barrier type PET bottle and product thereof

An oxygen barrier and product technology, which is applied in the field of preparation of oxygen barrier PET bottles, can solve the problems of difficult surface modification of nano-powders, complicated processes, poor compatibility, etc., and achieves elimination of hidden dangers of filler migration and stable chemical properties. , The effect of improving the barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

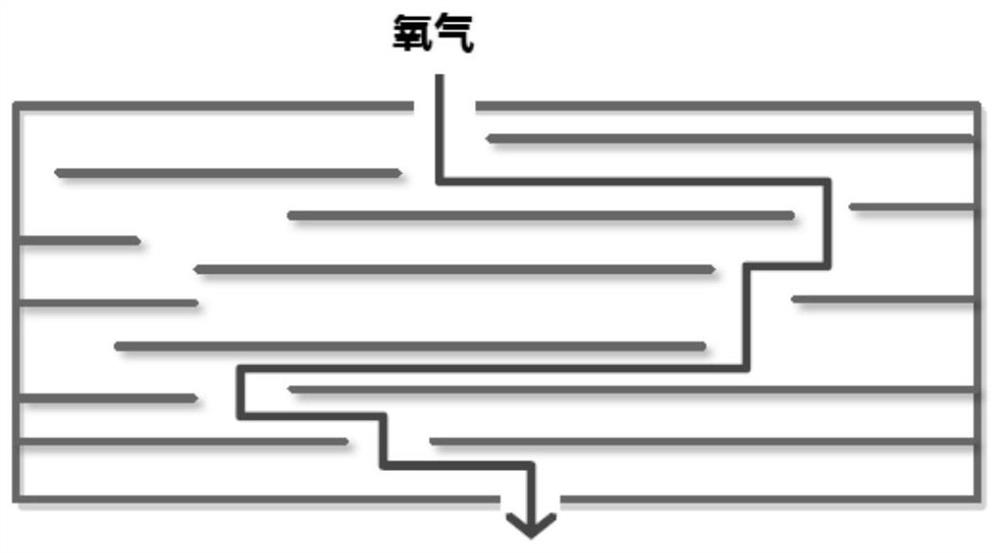

[0038] The present invention relates to a kind of preparation method of oxygen barrier type PET bottle, and described method step is as follows:

[0039] (1) First, add an appropriate amount of flaky alumina to deionized water, ultrasonically disperse and then filter with suction; then add ethylene glycol to the filtered flaky alumina, stir and then filter with suction, and repeat this operation 2-3 times;

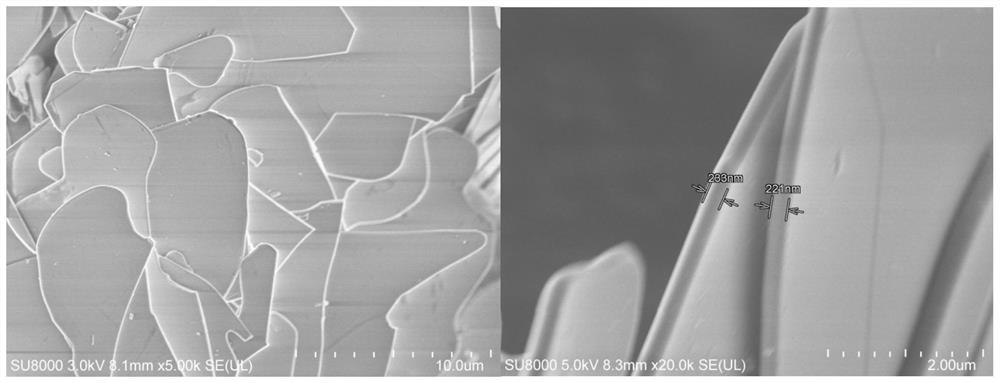

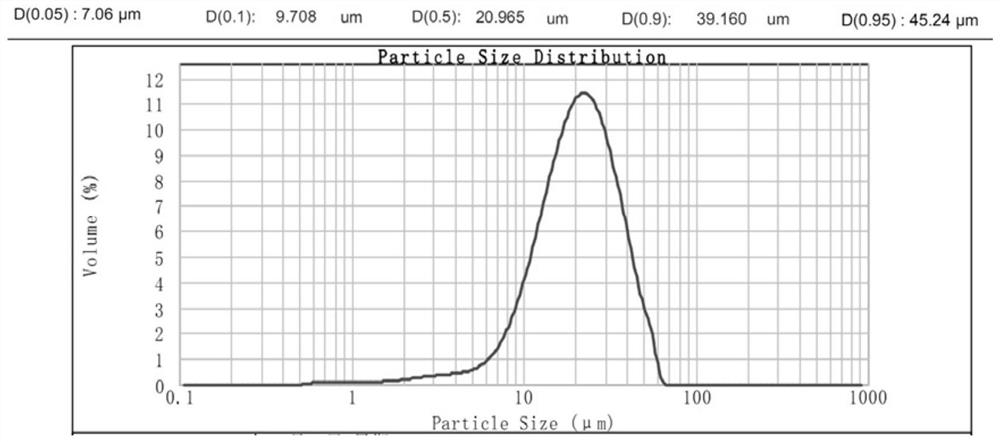

[0040] The flaky alumina is artificially synthesized; its structural feature is α-phase single-crystal alumina; its morphological feature is that the single-sheet diameter ranges from 5-30 μm and its thickness ranges from 100-400 nm;

[0041] (2) adding the water-dispersed and alcohol-substituted flaky alumina into the alcohol mixture, heating and refluxing in a water bath to react, and obtaining a surface-modified flaky alumina-alcohol mixed suspension;

[0042] (3) Add terephthalic acid, flaky alumina-alcohol mixture, and ethylene glycol antimony to the reactor successiv...

Embodiment 1

[0052] A preparation method of an oxygen barrier type PET bottle, the steps are as follows:

[0053] (1) First, add an appropriate amount of flaky alumina into a beaker filled with 10 times the mass of deionized water, use an ultrasonic disperser to disperse for 20 minutes, and then suction filter; then add 3 times the mass of ethylene glycol to the filtered flaky alumina Alcohol, after electric stirring at 200r / min speed for 10min, suction filtration, repeat this operation 2-3 times;

[0054] (2) Add water-dispersed and alcohol-substituted flaky alumina to 4 times the mass of the alcohol mixture, heat and reflux in a water bath at 90°C for 1 hour to obtain a surface-modified flaky alumina-alcohol mixed suspension ;

[0055] The alcohol mixture comprises ethylene glycol and polyethylene glycol, wherein the mass ratio content of ethylene glycol is 97%, and the mass ratio content of polyethylene glycol is 3%. The polyethylene glycol is polyethylene glycol 400.

[0056] (3) Ad...

Embodiment 2

[0060] (1) First, add an appropriate amount of flaky alumina into a beaker with 8 times the mass of deionized water, disperse it with an ultrasonic disperser for 10 minutes, and then filter it with suction; then add 2 times the mass of ethylene glycol to the filtered flaky alumina Alcohol, after electric stirring at 50r / min speed for 5min, suction filtration, repeat this operation 2-3 times;

[0061] (2) Add water-dispersed and alcohol-substituted flaky alumina to 3 times the mass of alcohol mixture, heat and reflux in a water bath at 95°C for 0.5h to obtain a surface-modified flaky alumina-alcohol mixed suspension liquid;

[0062] The alcohol mixture comprises ethylene glycol and polyethylene glycol, wherein the mass ratio content of ethylene glycol is 99%, and the mass ratio content of polyethylene glycol is 1%. The polyethylene glycol is polyethylene glycol 1000.

[0063] (3) Add 100 parts of refined terephthalic acid, 70 parts of flaky alumina-alcohol mixed solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com