Large-stroke handle with sector gear

A sector gear, large stroke technology, applied in the field of large stroke handles, can solve the problems of large panel shape, affecting the appearance of the opening fan, low applicability of window profiles, etc., to achieve the effect of increasing the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

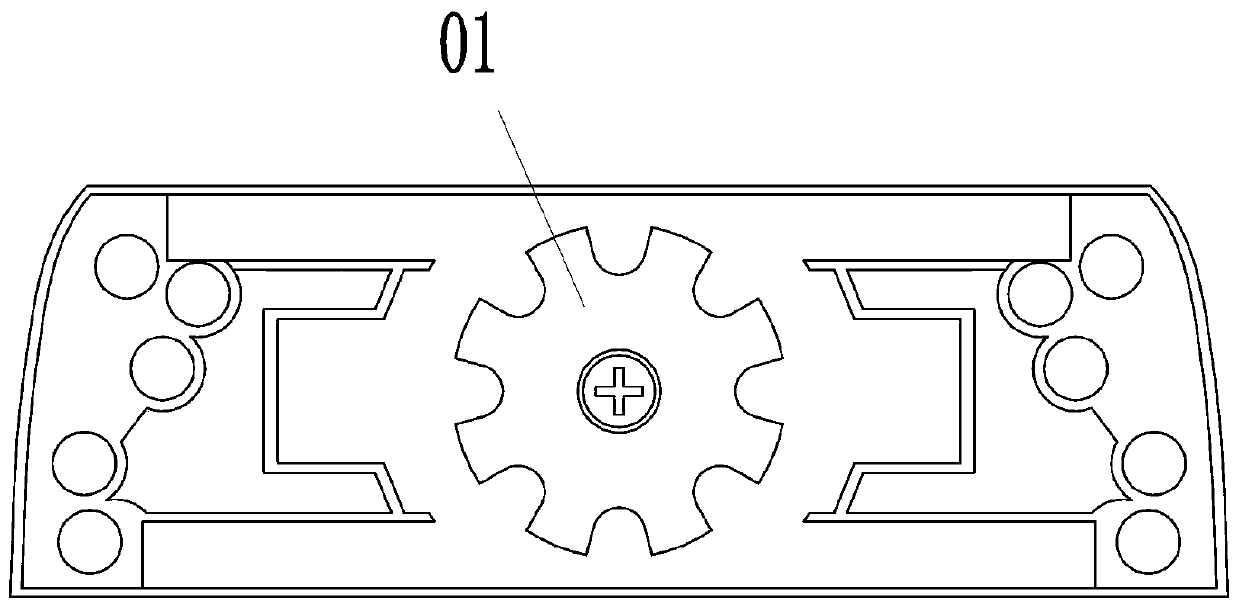

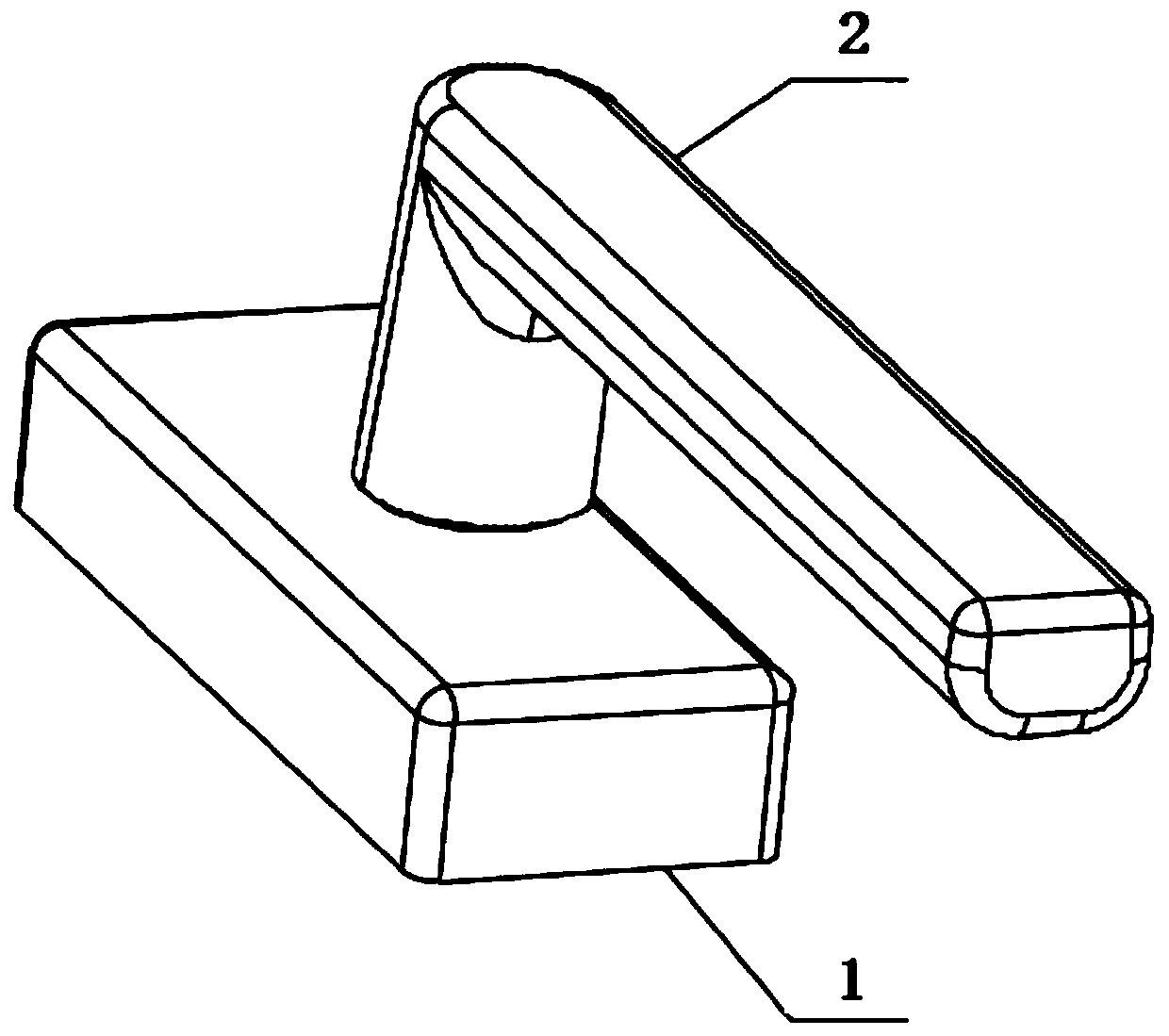

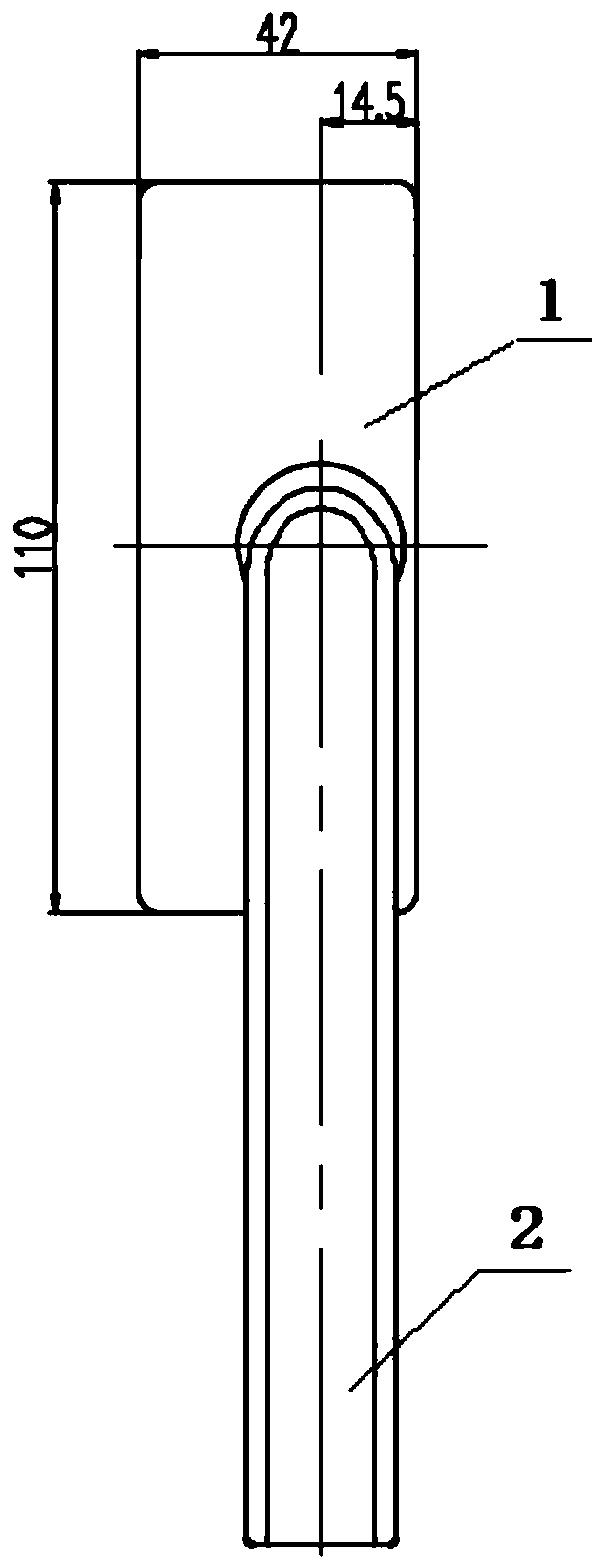

[0065] Such as Figure 2 to Figure 11 As shown, the large stroke handle of the sector gear provided by the present invention includes a panel case 1 , a handle 2 , a sector gear 3 , a shift fork with a rack 4 , a top ball assembly 5 and a protection sheet 8 .

[0066] Such as Figure 10a to Figure 10c As shown, the panel housing 1 is a semi-open housing including a bottom plate and surrounding side walls. In the panel housing 1, the rack slideway 11, the protection sheet insertion slot 12 and the top bead assembly are formed by ribs 10. The notch 13 is installed, and the gear shaft hole 14 is located centrally on the symmetrical axis in the longitudinal direction of the panel housing 1 . In the width direction of the panel housing 1 , the gear shaft hole 14 is disposed on one side. The upper surfaces of each rib 10 are flush on a horizontal plane.

[0067] Such as Figure 6 and Figure 6a As shown, a top ball assembly 5 is set in the mounting notch 13 of the top ball assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com