Side anchor rod drilling carriage

A technology for assisting rock bolts and drilling rigs, which is applied in the field of mining mechanized equipment. It can solve the problems of affecting the progress of excavation, low efficiency of assisting bolt drilling rigs, and inflexible transportation, so as to improve operation efficiency, efficiently assist bolt operations, The effect of flexible deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

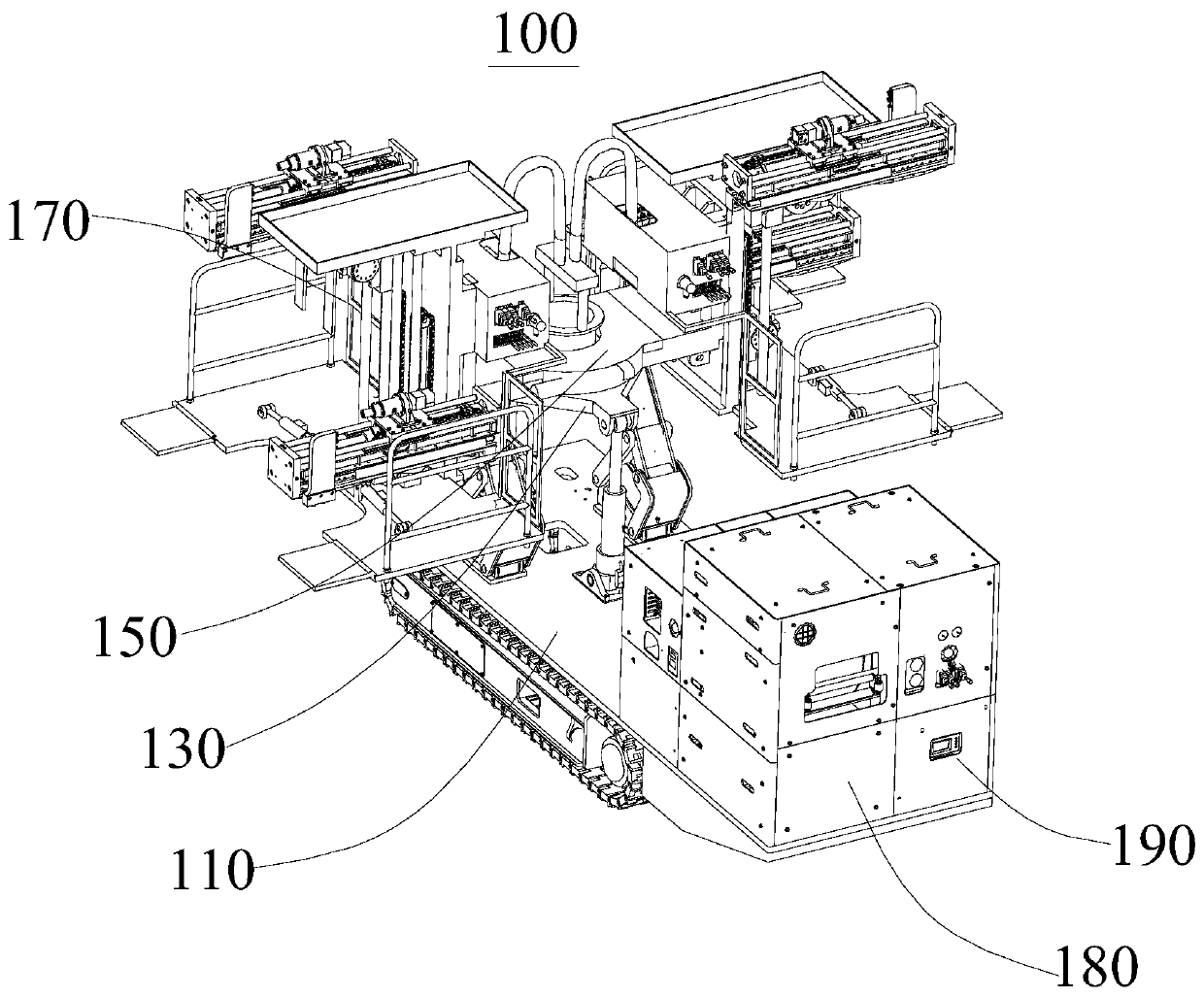

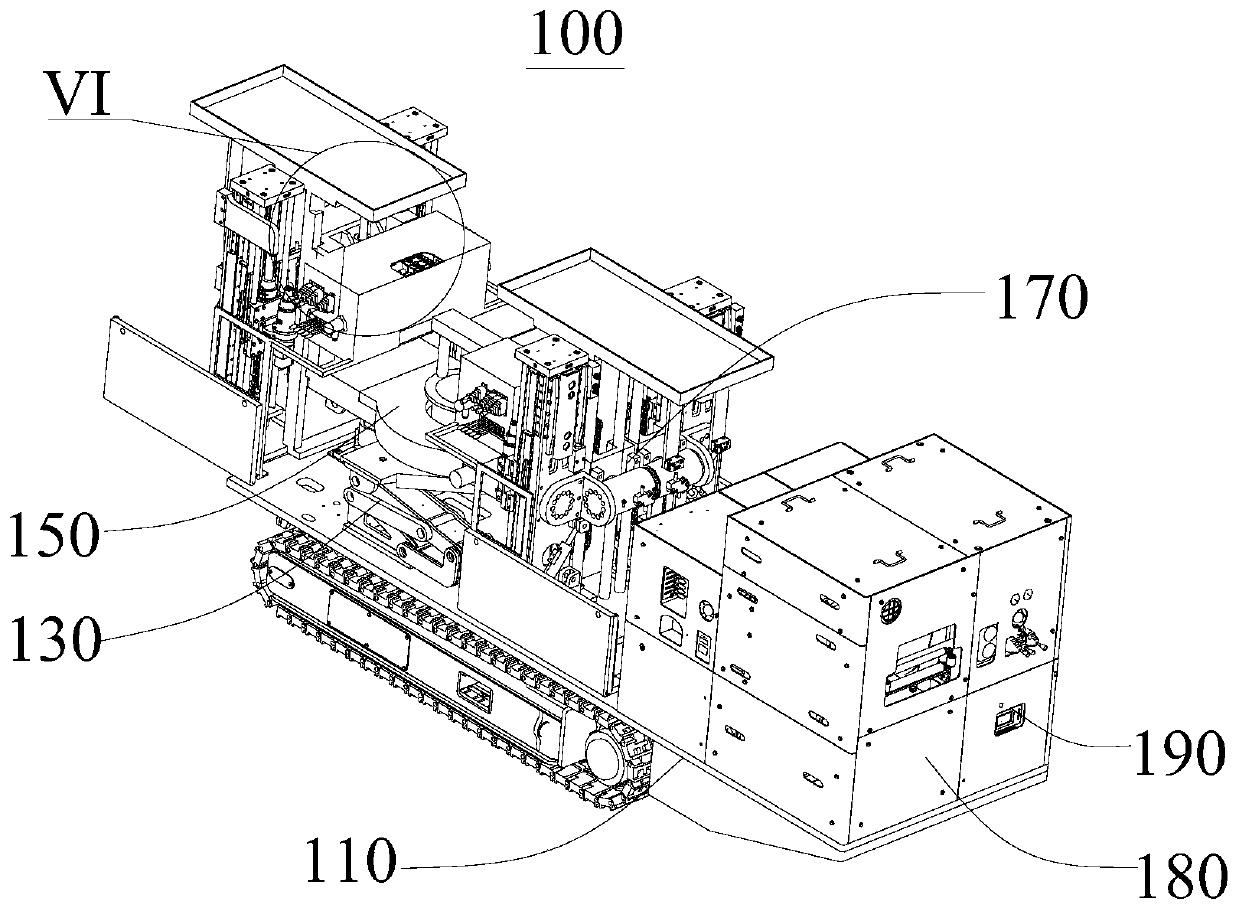

[0034] see in conjunction figure 1 and figure 2 , this embodiment provides a side rock bolt drilling rig 100, which is used for side rock bolt and anchor cable construction operations, and has the advantages of wide adaptability, flexible transportation, high operating efficiency, fast hole finding and positioning speed, comfortable and safe operation .

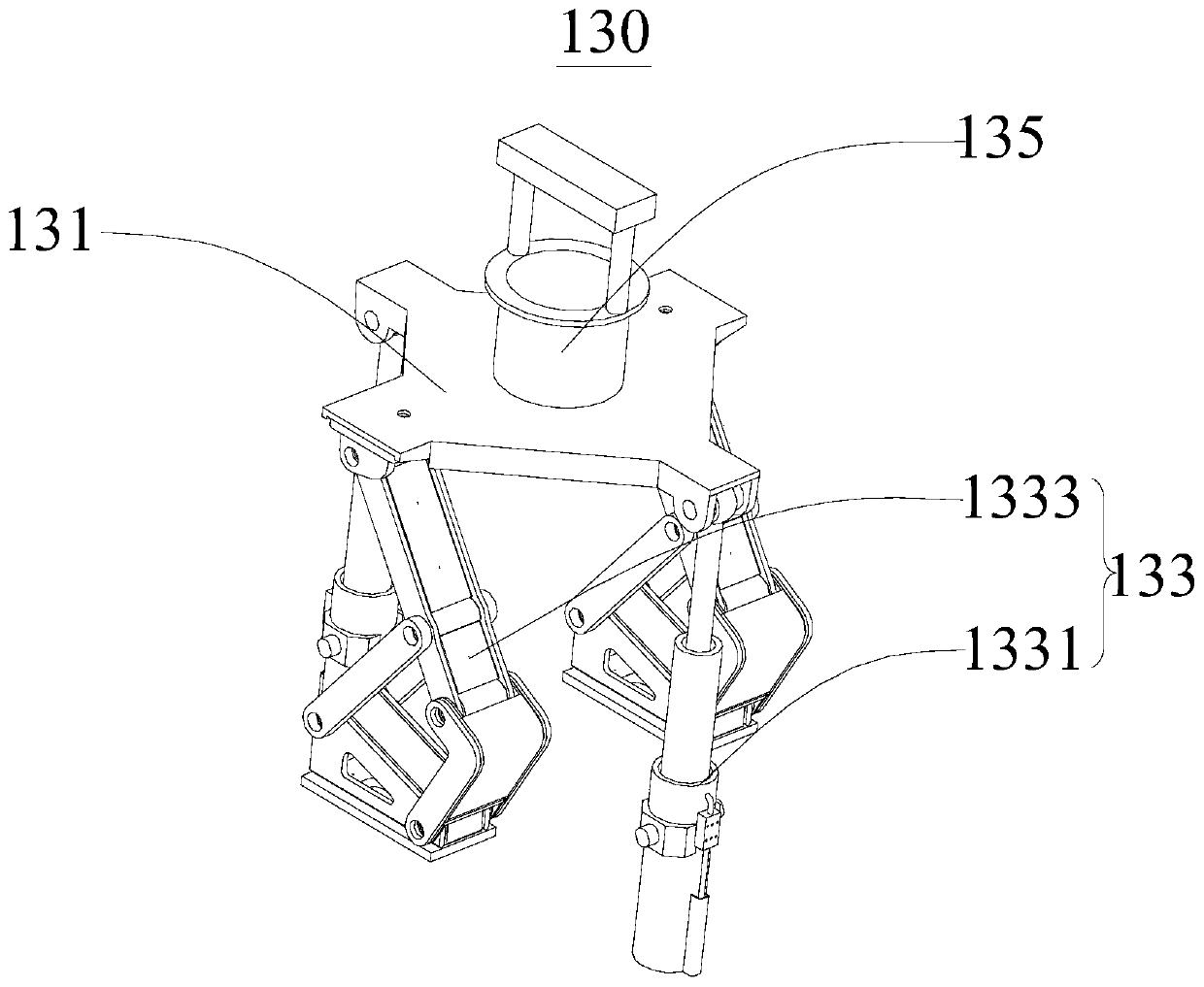

[0035] The rock bolter rig 100 provided in this embodiment includes a traveling chassis 110, a lifting mechanism 130, a rotary mechanism 150 and two drilling parts 170. The lifting mechanism 130 is arranged on the traveling chassis 110, and the rotary mechanism 150 is rotatably arranged on the lifting mechanism. On the top of 130, two drilling parts 170 are respectively installed on the two ends of the rotary mechanism 150, and can follow the rotation of the rotary mechanism 150 relative to the lifting mechanism 130.

[0036] In this embodiment, an electrical system 180 and a hydraulic system 190 are provided at the rear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com