Thermal shock device and method for shield tunneling machine

A technology of shield machine and thermal shock, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc. It can solve the problems of reducing the difficulty of excavation and wear of the cutter head, and achieve the effect of accelerating rock breaking speed, reducing torque and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

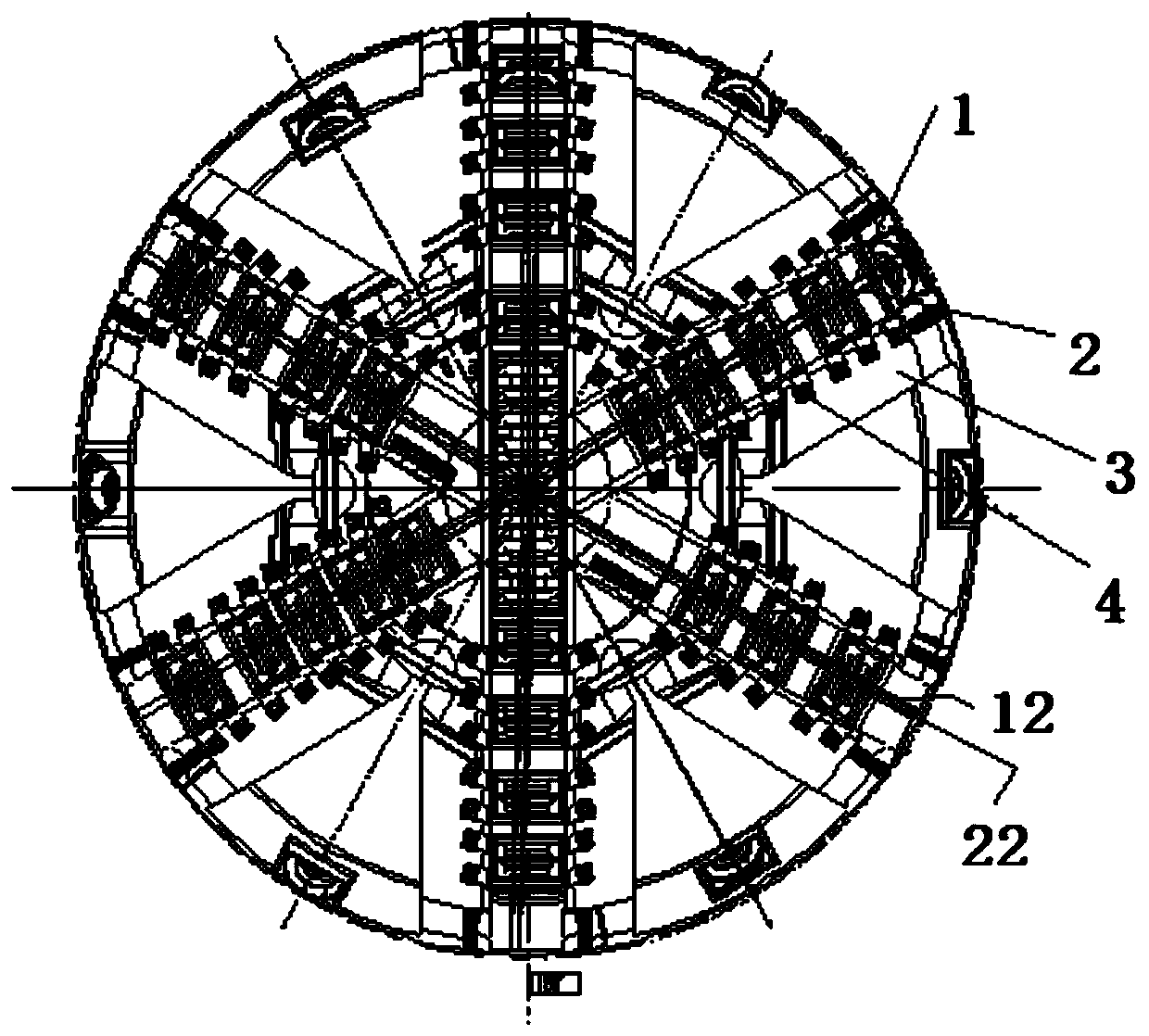

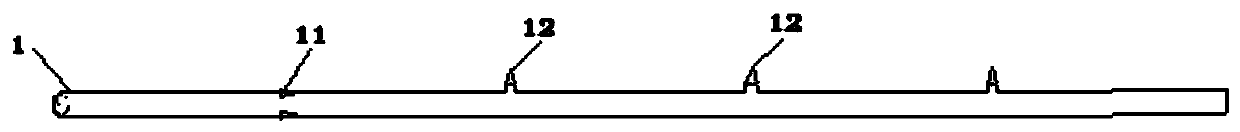

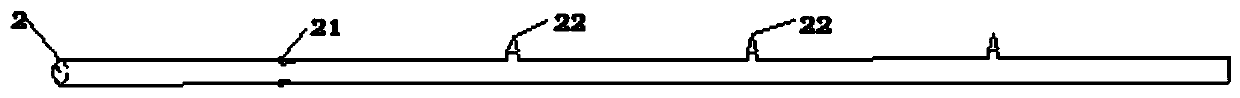

[0026] Such as Figure 1-Figure 3 As shown, this embodiment provides a thermal shock device for a shield machine, including a temperature measuring device arranged on the cutter head 3 and arranged in parallel on the end surface of the cutter head 3 of the shield machine and evenly distributed along the circumference of the cutter head 3 The heating pipe 1 and the cooling pipe 2; the heating pipe 1 is provided with a number of ignition devices 12 sequentially arranged along the length direction of the heating pipe 1 and a heating switch 11 for controlling the ignition device 12 on the end surface of the heating pipe 1 facing away from the cutter head 3 ; The cooling pipe 2 is provided with a number of cooling nozzles 22 arranged sequentially along the length direction of the cooling pipe 2 and a cooling switch 21 for controlling the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com