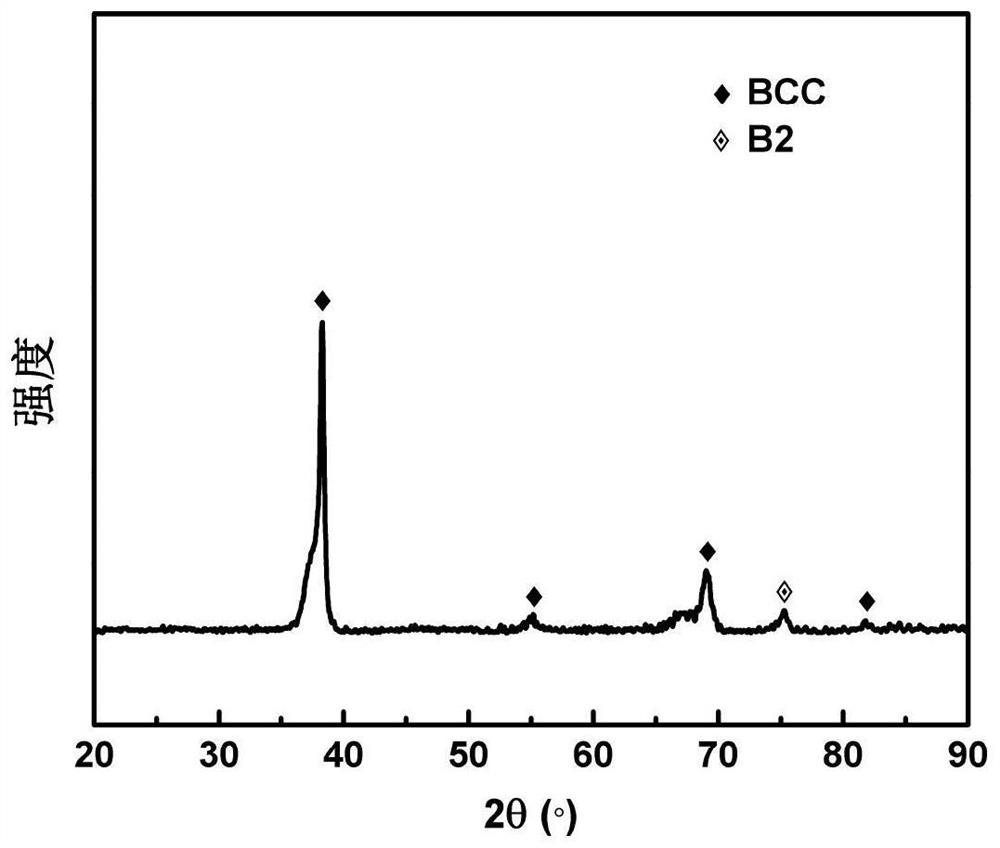

Multi-principal-element alloy containing BCC/B2 double-phase structure and preparation method of multi-principal-element alloy

A multi-principal alloy, phase structure technology, applied in the field of metal materials, can solve the problems of incompatibility between strength and plasticity, and achieve the effect of improving high temperature oxidation resistance, good plasticity, and deteriorating mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

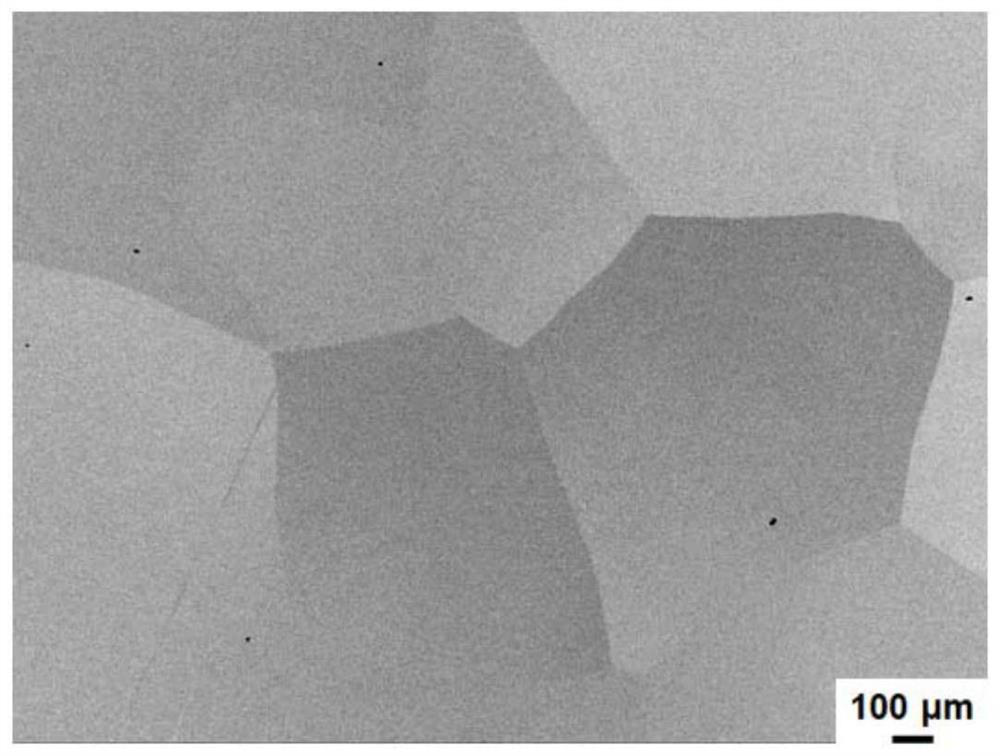

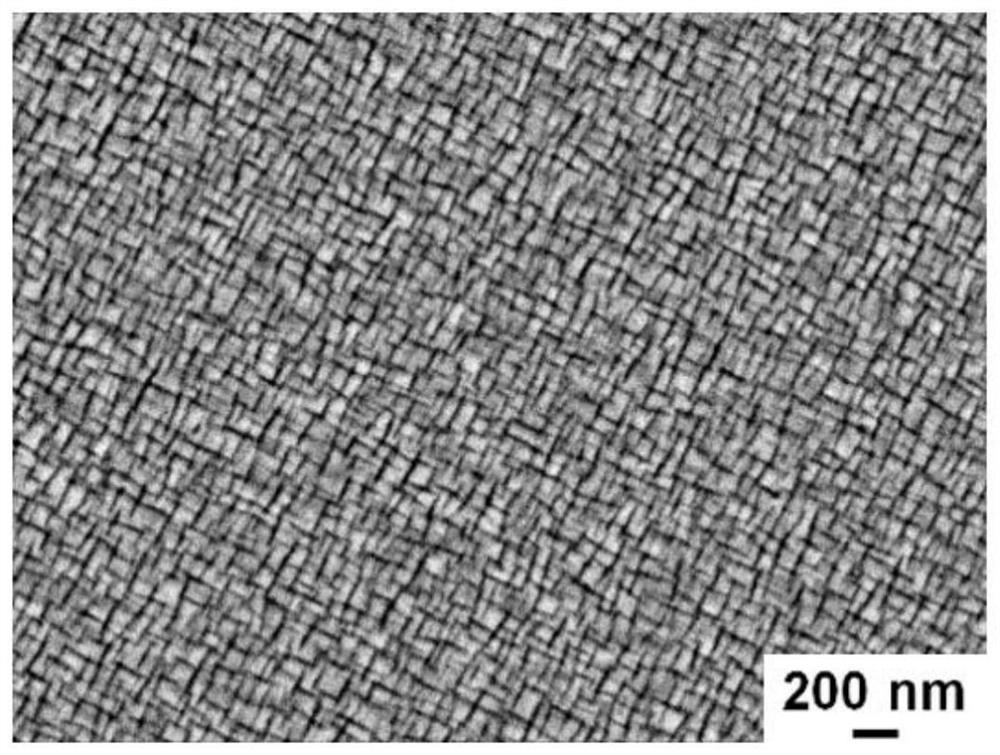

[0039] A multi-principal alloy of BCC / B2 dual-phase structure, its constituent elements and the atomic percentages of each element are as follows: titanium (Ti) 33.25at.%, tantalum (Ta) 14.25at.%, niobium (Nb) 23.75 at.%, zirconium (Zr) 23.75 at.%, and aluminum (Al) 5 at.%. The steps of the preparation method of the multi-principal alloy are as follows:

[0040] (1) Weigh the elemental substances of Ti, Ta, Nb, Zr and Al with a purity greater than 99.9wt.% according to the atomic percentage, and put them into the crucible of the non-consumable vacuum arc melting furnace according to the melting point of the elemental substances from low to high, and place Vacuum the furnace to ≤5×10 - 3 Argon gas is introduced after Pa, and then alloyed and smelted. The alloy liquid formed by melting is cooled to room temperature in a water-cooled copper mold to obtain an alloy ingot, and then the alloy ingot is turned over and smelted repeatedly for 6 times to obtain an alloy ingot;

[004...

Embodiment 2

[0045] A multi-principal alloy of BCC / B2 dual-phase structure, its constituent elements and the atomic percentages of each element are as follows: titanium (Ti) 31.5 at.%, tantalum (Ta) 13.5 at.%, niobium (Nb) 22.5 at.%, zirconium (Zr) 22.5 at.%, and aluminum (Al) 10 at.%. The steps of the preparation method of the multi-principal alloy are as follows:

[0046] (1) Weigh the elemental substances of Ti, Ta, Nb, Zr and Al with a purity greater than 99.9wt.% according to the atomic percentage, and put them into the crucible of the non-consumable vacuum arc melting furnace according to the melting point of the elemental substances from low to high, and place Vacuum the furnace to ≤5×10 - 3 Argon gas is introduced after Pa, and then alloyed and smelted. The alloy liquid formed by melting is cooled to room temperature in a water-cooled copper mold to obtain an alloy ingot, and then the alloy ingot is turned over and smelted repeatedly for 6 times to obtain an alloy ingot;

[0047...

Embodiment 3

[0051] A multi-principal alloy of BCC / B2 dual-phase structure, its constituent elements and the atomic percentage of each element are as follows: titanium (Ti) 42at.%, tantalum (Ta) 8at.%, niobium (Nb) 15at.% , zirconium (Zr) 25at.%, aluminum (Al) 9at.%, and chromium (Cr) 1at.%. The steps of the preparation method of the multi-principal alloy are as follows:

[0052] (1) Weigh the elemental substances of Ti, Ta, Nb, Zr, Al and Cr with a purity greater than 99.9wt.% according to the atomic percentage, and put them into the crucible of the non-consumable vacuum arc melting furnace according to the melting point of the elemental substances from low to high , vacuum the furnace to ≤5×10 -3 Argon gas is introduced after Pa, and then alloyed and smelted. The alloy liquid formed by smelting is cooled to room temperature in a water-cooled copper mold to obtain an alloy ingot, and then the alloy ingot is turned over and repeatedly smelted 5 times to obtain an alloy ingot;

[0053] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com