Nano-structure low-activation martensitic steel and preparation method thereof

A nano-structured martensitic steel technology, applied in the field of metal materials, can solve the problems of low activation steel preparation cost, increase, inability to fully exert the effect of Ti precipitation strengthening, etc., and achieve the effect of avoiding comprehensive mechanical properties and avoiding a sharp increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

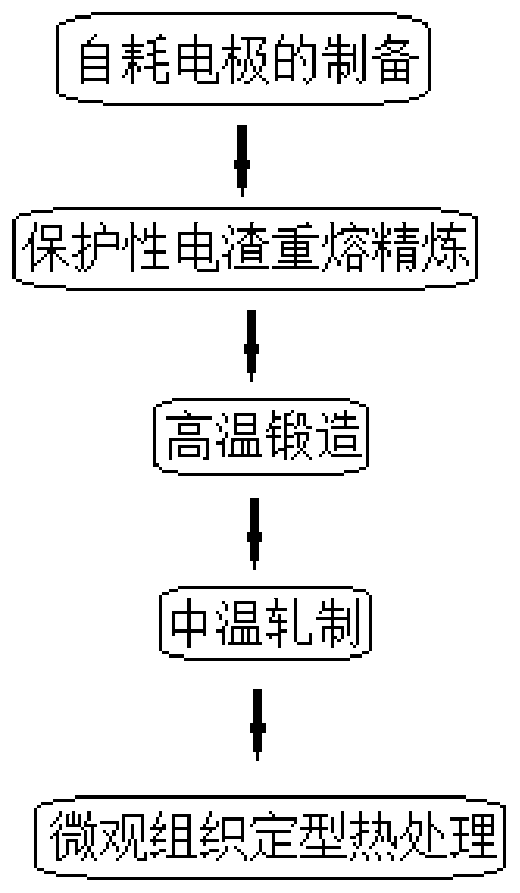

[0037] The preparation method of nanostructure low-activation martensitic steel of the present invention, it comprises the following steps:

[0038] (1) Preparation of consumable electrodes

[0039] Dosing and melting are carried out according to the low activation steel composition. Put Fe, Cr, W and C in a vacuum induction furnace for smelting, and then refine after the alloy is melted. The refining time is 50-70min, the refining temperature is 1600-1610°C, and the vacuum degree is 10-20Pa. After refining, reduce the power of the induction furnace to reduce the temperature of the alloy liquid to 1540-1550 °C, and add the remaining alloys from the alloy silo to the alloy liquid in the following order: Si→Mn→V→Ti, with a time interval of 1-1.5 minutes. After all the alloys are melted, nitrogen gas is introduced into the induction furnace to keep the pressure in the induction furnace at 2000-4000Pa, and the casting is carried out under nitrogen environment, and the casting te...

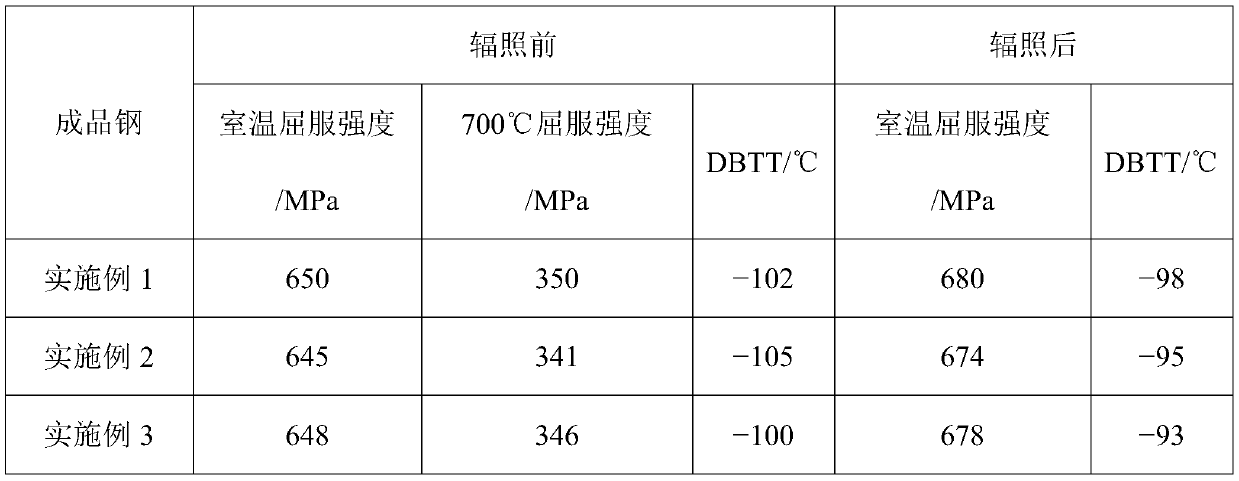

Embodiment 1

[0049] In the nanostructured low-activation martensitic steel of this embodiment, in terms of mass percentage, the contents of each component are: C 0.1%, Si 0.1%, Mn 0.45%, Cr 9.0%, W 1.45%, V 0.20% , Ti 0.015%, N 0.0075%, and the balance is Fe.

[0050] The preparation process of the nanostructured low-activation martensitic steel in this embodiment includes the following steps:

[0051] (1) Preparation of consumable electrodes

[0052] Dosing and melting are carried out according to the low activation steel composition. Put Fe, Cr, W and C in a vacuum induction furnace for smelting, and then refine after the alloy is melted. The refining time is 60min, the refining temperature is 1605-1610°C, and the vacuum degree is 10-15Pa. After refining, reduce the power of the induction furnace to reduce the temperature of the alloy liquid to 1545-1550 °C, and add the remaining alloys from the alloy silo to the alloy liquid in the following order: Si→Mn→V→Ti, with a time interval of...

Embodiment 2

[0063] In the nanostructured low-activation martensitic steel of this embodiment, the content of each component is: C 0.12%, Si 0.2%, Mn 0.4%, Cr 9.5%, W 1.0%, V 0.18% by mass percentage , Ti 0.01%, N 0.01%, and the balance is Fe.

[0064] The preparation process of the nanostructured low-activation martensitic steel in this embodiment includes the following steps:

[0065] (1) Preparation of consumable electrodes

[0066] Dosing and melting are carried out according to the low activation steel composition. Put Fe, Cr, W and C in a vacuum induction furnace for smelting, and then refine after the alloy is melted. The refining time is 60min, the refining temperature is 1600-1605°C, and the vacuum degree is 10-15Pa. After refining, reduce the power of the induction furnace to reduce the temperature of the alloy liquid to 1545-1550°C, and add the remaining alloys from the alloy silo to the alloy liquid in the following order: Si→Mn→V→Ti, with a time interval of 1min. After all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com