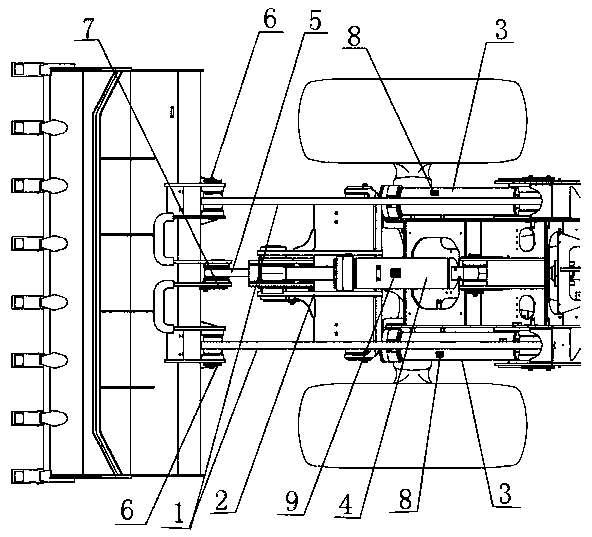

Loader shoveling and loading operation resistance real-time testing method based on position calculation

A real-time test and loader technology, applied in force/torque/power measuring instruments, measuring devices, measuring force components, etc., can solve problems such as inaccurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

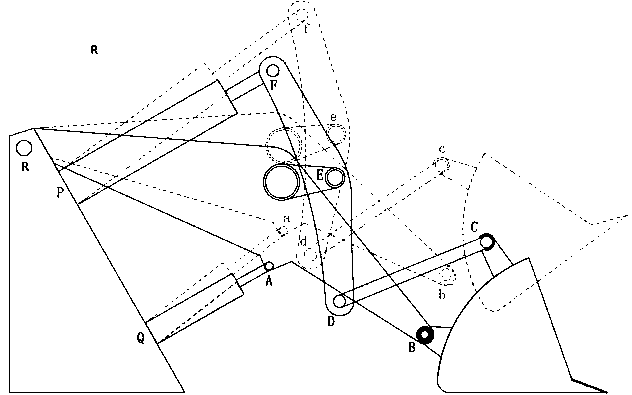

[0068] Such as image 3 with Figure 4 , where the solid line is the initial position of the bucket entering the shoveling position, and the dotted line is the position of the bucket at this time node;

[0069] The real-time test method for loader shovel loading operation resistance based on position calculation includes the following steps:

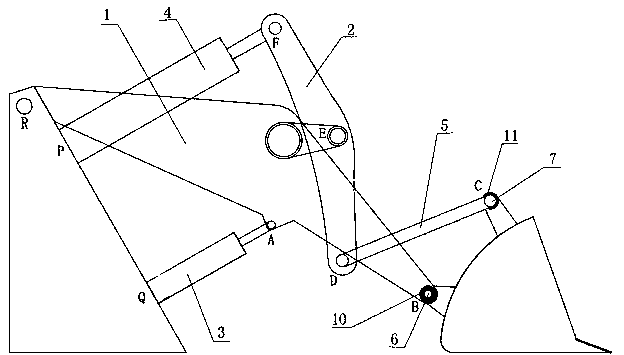

[0070] A. Set the hinged installation point of the boom 1 on the shovel loading part of the loader as R, set the installation point position of the boom cylinder 3 as Q, and set the hinged installation point position of the bucket cylinder 4 as P;

[0071] When the shoveling part of the loader enters the shoveling position, set the hinge point position of the left and right boom 1 and rocker 2 as E, and set the boom pin 1 at the joint between the left and right boom 1 of the loader and the bucket Set the position of the pivot point of the boom cylinder 3 to B, set the position of the hinge point of the piston rod of the boom cylinder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com