Spinning type coarse-grained soil triaxial experiment sample preparation device and sample preparation method

A triaxial experiment, coarse-grained soil technology, applied in sampling, instruments, scientific instruments, etc., can solve the difficulty in controlling the uniformity and compactness of the sample density, affect the mechanical properties of the sample, and coarse-grained soil structure Damage and other problems, to achieve the effect of uniform sample preparation, convenient operation, and meet the experimental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

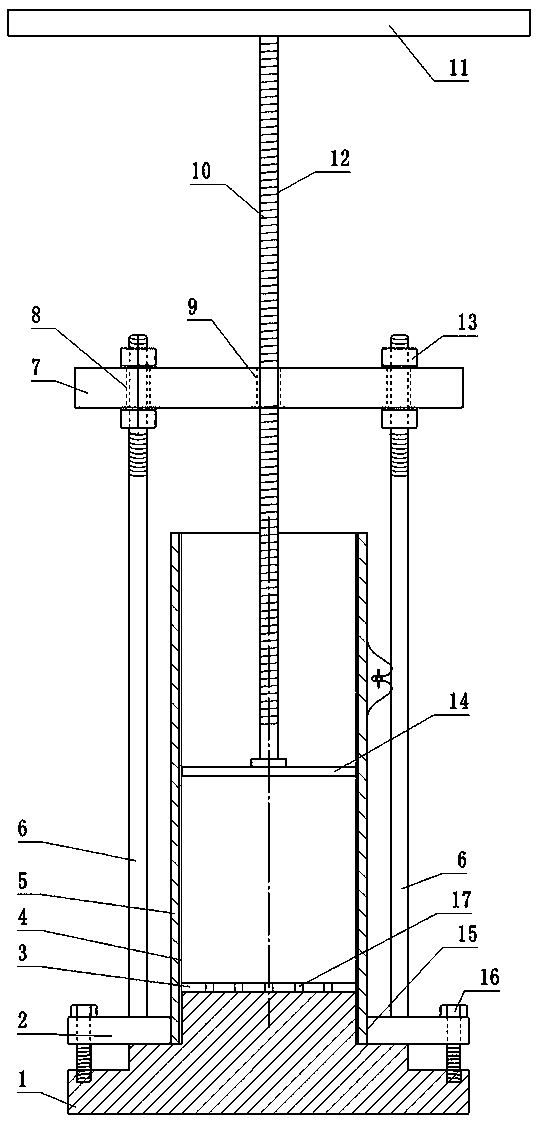

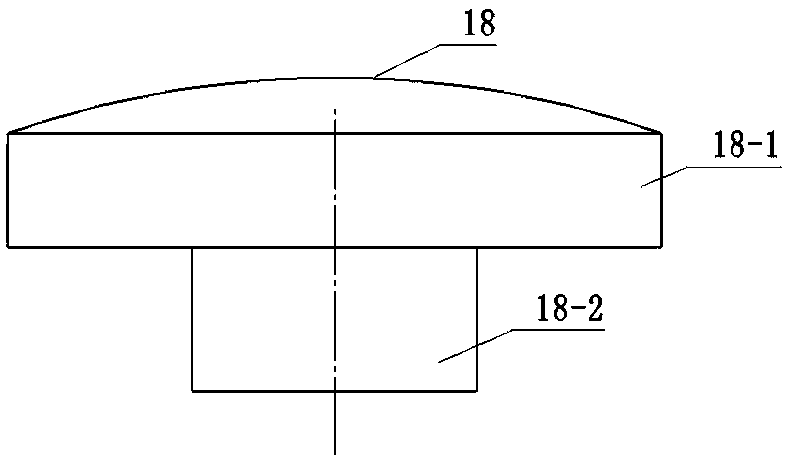

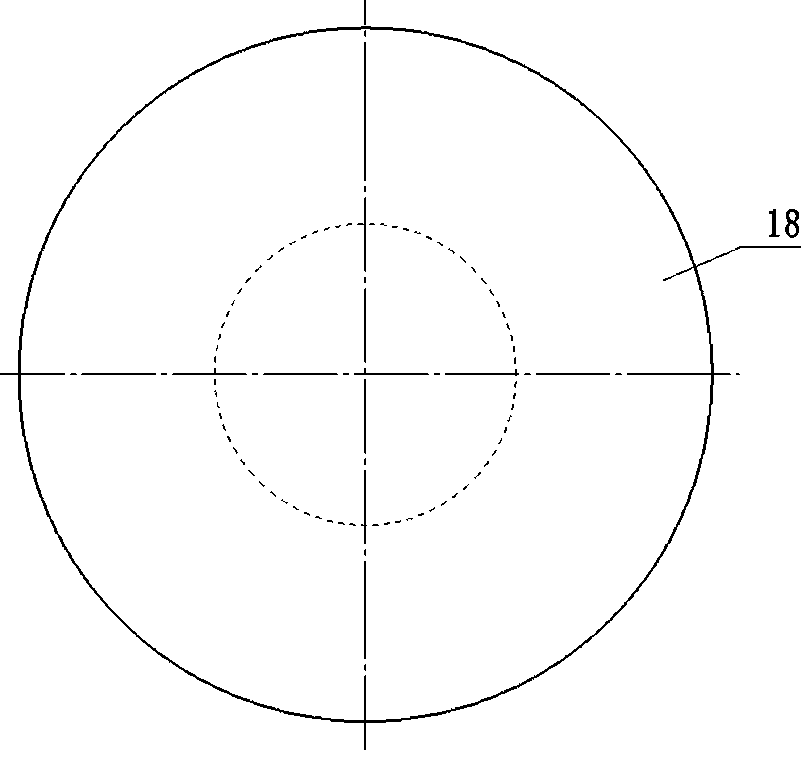

[0048] refer to figure 1 - Figure 14 , is a structural schematic diagram of an embodiment of the present invention, a spinning type coarse-grained soil triaxial experimental sample preparation device, mainly including a base 1, a reaction force frame, a rubber film 4, a sample preparation cylinder 5, a spinning device, and a water-permeable plate 3 , sample cap 18;

[0049] The base 1 includes upper, middle and lower layers of cylindrical bosses with different diameters, namely the upper boss 19, the middle boss 20, and the lower boss 21; the reaction force frame includes an annular bottom plate 2, a rigid reaction column 6. Reaction force cover plate 7, the lower end of the rigid reaction force column 6 is fixed on the annular bottom plate 2, the reaction force cover plate 7 is provided with a round hole 8, the upper end of the rigid reaction force column 6 is provided with threads, rigid The upper end of the reaction force column 6 passes through the circular hole 8 on th...

Embodiment 2

[0060] refer to figure 1 - Figure 14 , a sample preparation method utilizing the spinning type coarse-grained soil triaxial experimental sample preparation device described in Example 1, mainly comprising the following steps:

[0061] (1) Insert and fasten the rubber film 4 on the outer wall of the upper boss 19 of the base 1 to ensure that the bottom of the rubber mold 4 is pulled to the bottom of the upper boss 19 and adheres to the outer wall of the upper boss 19;

[0062] (2) Set the annular bottom plate 2 fixedly connected with four rigid reaction force columns 6 on the periphery of the upper boss 19 of the base 1, rotate and align with the screw holes of the lower boss 21 of the lower base, and insert the bolts;

[0063] (3) Install the sample preparation cylinder: put three arc-shaped steel templates 25 into the gap between the inner diameter side of the annular bottom plate 2 of the reaction frame and the outer side of the rubber film 4 in sequence, and fix the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com