A high-efficiency crushing device for mining machinery and its application method

A technology for mining and machinery, applied in the field of high-efficiency smashing devices for mining machinery, can solve the problems of insufficient fixing, inconvenient storage, easy to slide, etc., and achieve the effects of convenient storage, reducing vibration and avoiding sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

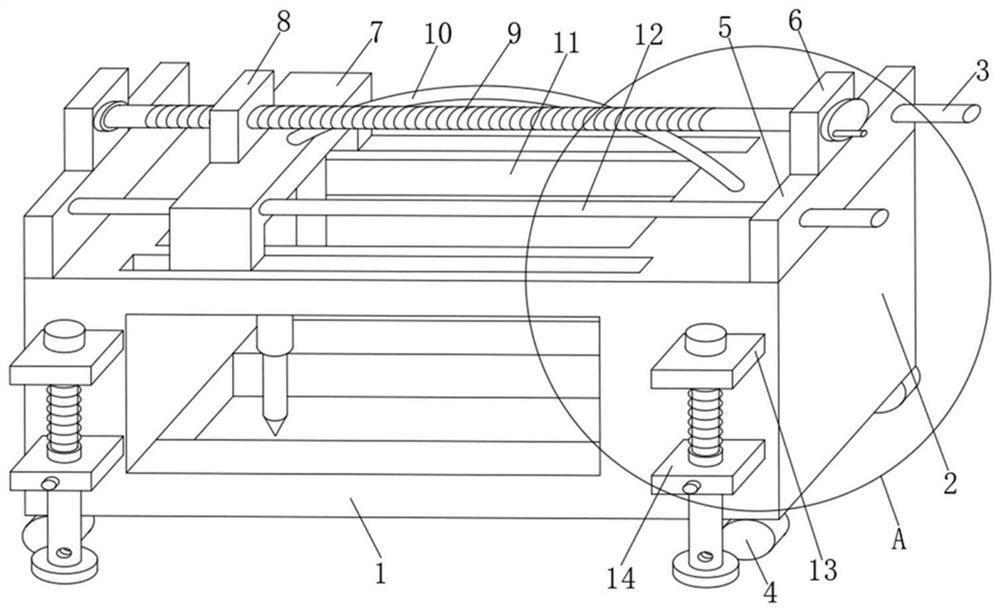

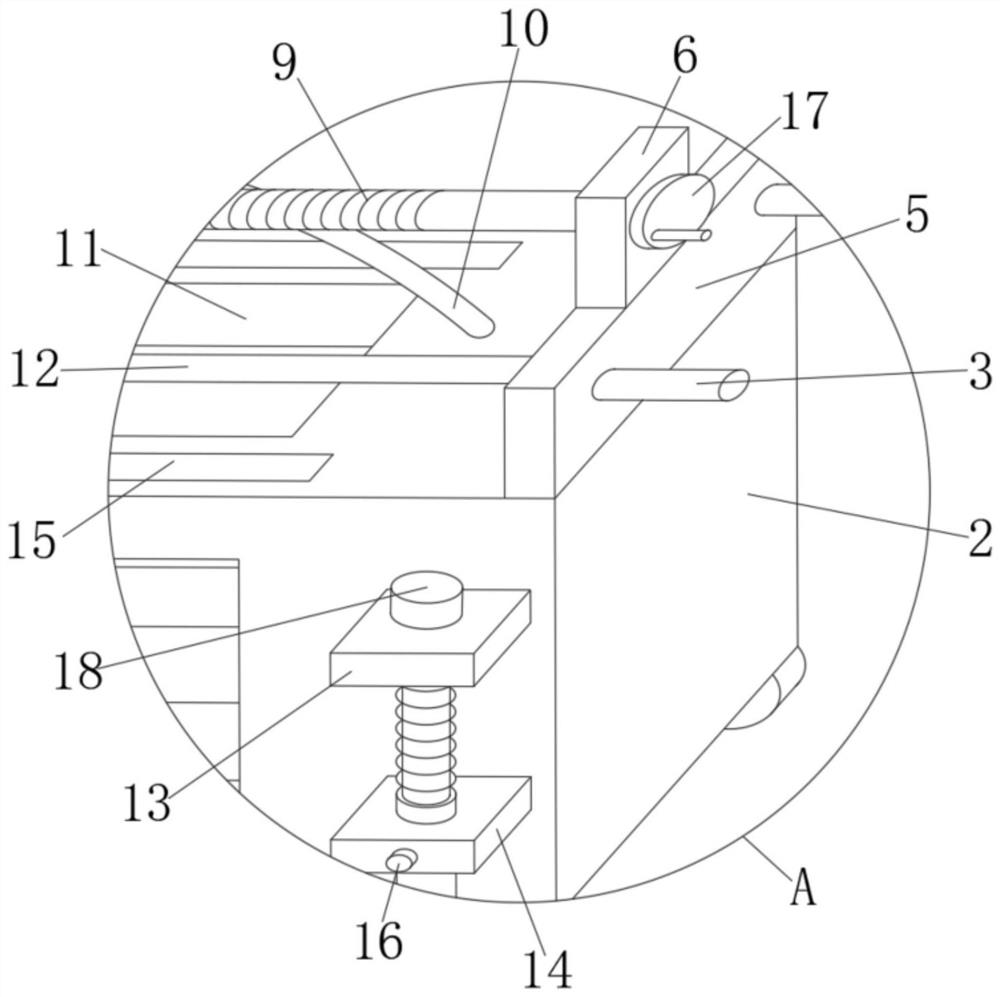

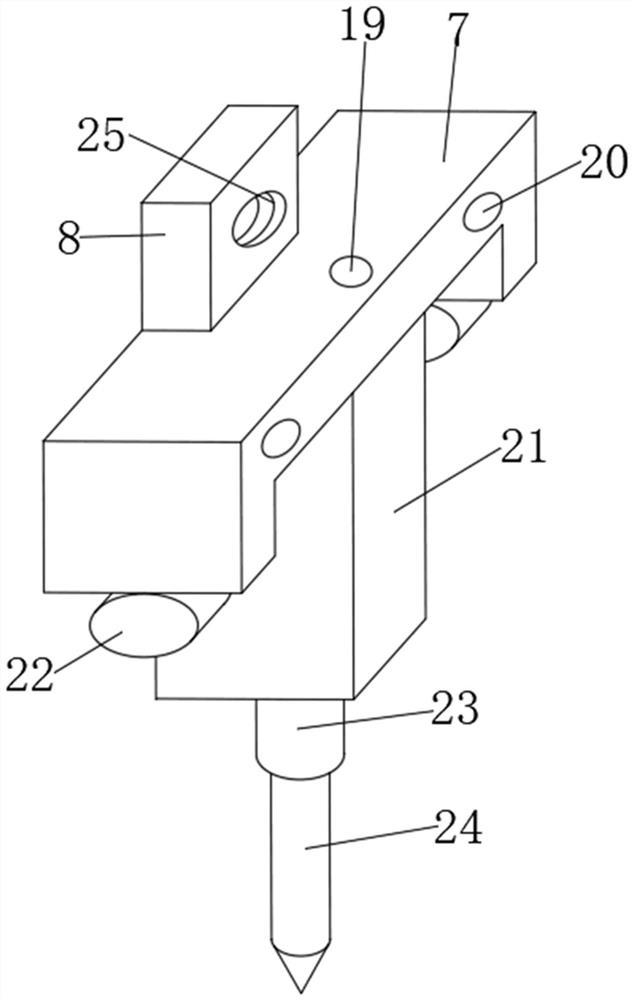

[0029] like Figure 1-7As shown, a high-efficiency crushing device for mining machinery includes a main frame 1, a side of the main frame 1 is provided with a storage box 2, the lower end of the main frame 1 is provided with four sets of road wheels 4, and the upper end of the main frame 1 is provided with There is a main body groove 11, and the interior of the main body groove 11 is provided with a transmission box 21. The upper end of the transmission box 21 is fixedly equipped with a sliding frame 7, and two sets of No. 1 side plates 13 and No. 2 side plates are respectively fixedly installed on both sides of the main body frame 1. 14. There is a No. 1 through hole on the No. 2 side plate 14. A fixed rod 37 is arranged inside the No. 1 through hole. A fixed pad 38 is fixedly installed on the lower end of the fixed rod 37. The transmission box 21 provided can be used in mines or rock mining. When the rock is crushed, and by moving the sliding frame 7, the transmission box 21...

Embodiment 2

[0036] A method for using a high-efficiency crushing device for mining machinery, the specific steps are as follows:

[0037] Step 1: Move the device to the place where the crushing operation is required, and separate it from the thread groove 39 by turning the fastening bolt 16, and under the action of the extrusion spring 40, the fixed rod 37 and the fixed pad 38 move downward to fix the The pad 38 is in contact with the ground, so that the device is fixed more firmly;

[0038] Step 2: Control the telescopic rod 27 to expand and contract inside the hydraulic cylinder 32 through the solenoid valve 28, so that the impact cylinder 23 moves up and down, the motor 33 adjusts the regulating valve 34, and the cylinder 35 transmits gas to the impact cylinder 23 through the air transmission pipe 10 , so that the impact rod 24 moves up and down inside the impact cylinder 23, thereby realizing the crushing operation on ground rocks. The buffer spring 31 arranged between the No. 1 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com