Metal impurity removing device of flash dryer

A technology of flash drying machine and metal impurities, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc. It can solve the problems of product quality reduction, equipment damage, metal impurities mixing, etc., and achieve the effect of simple structure and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

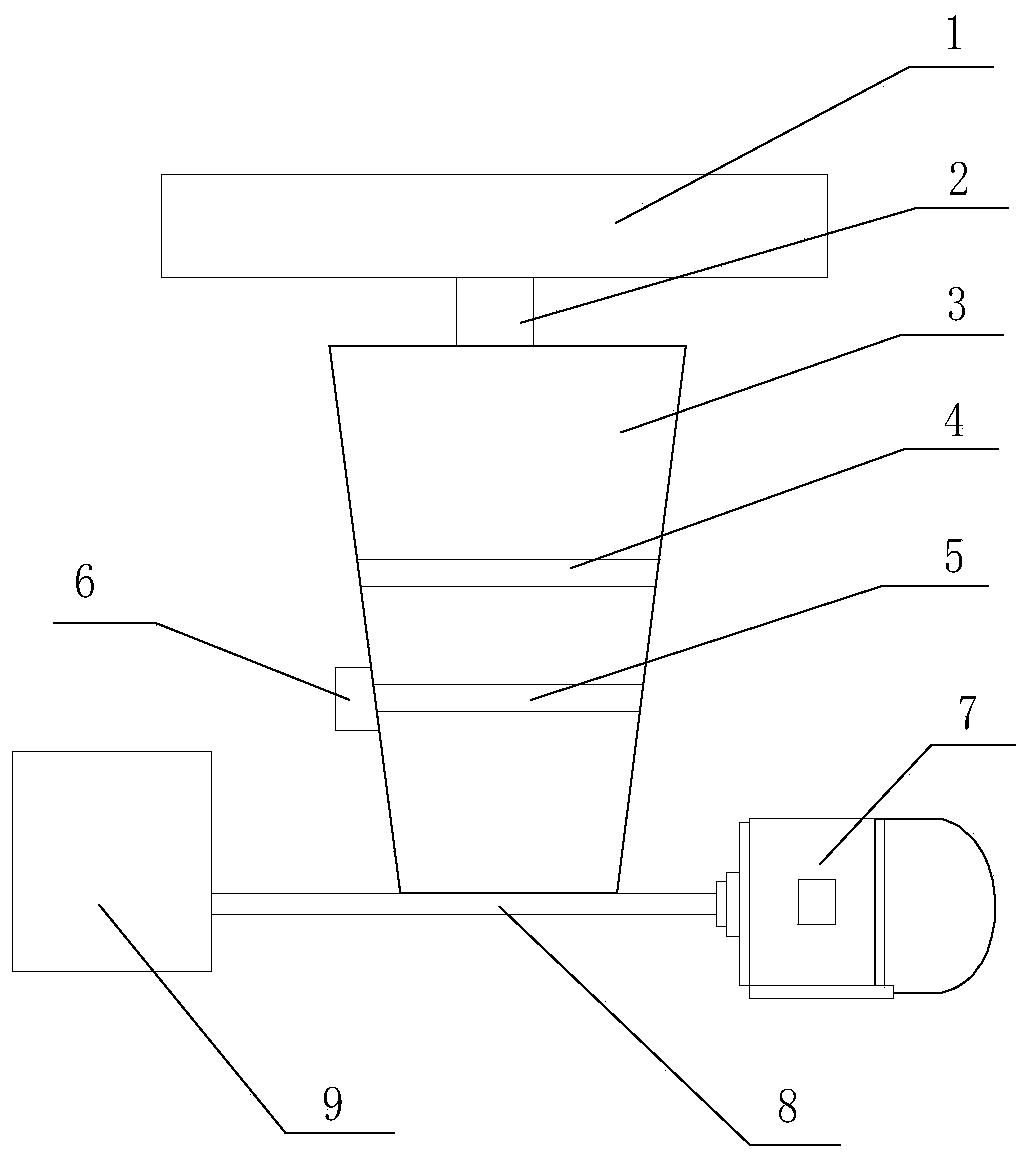

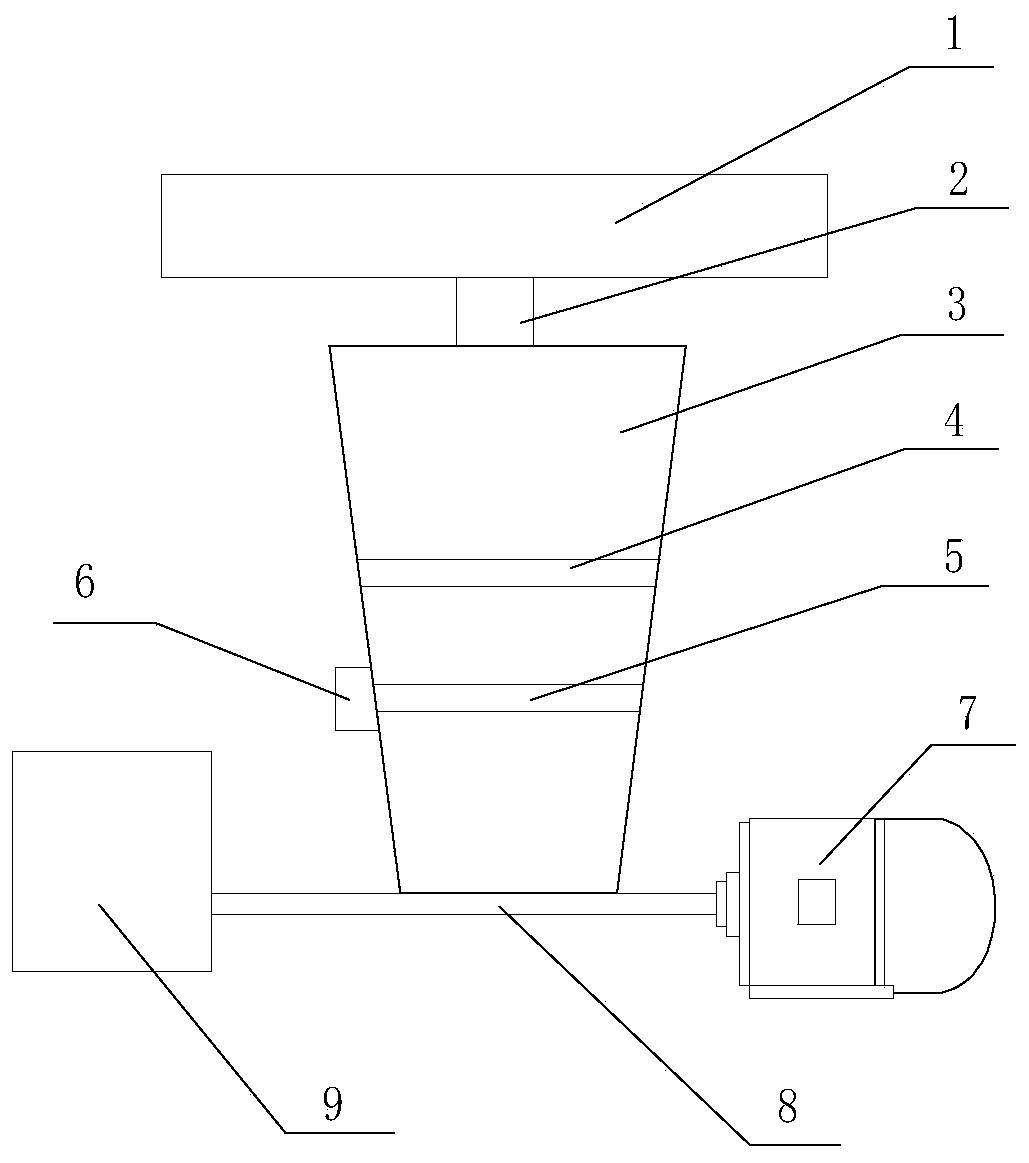

[0012] like figure 1 As shown, the present invention includes a feeding bin 3, and the feeding bin 3 is a cylindrical structure whose bottom gradually shrinks inward. The top of feeding bin 3 is provided with feed storage tank 1, and feed storage tank 1 is used for storing tetrabromobisphenol A material, and its bottom is connected with feeding bin 3 tops by feeding pipe 2, and the described feeding bin 3 The bottom outlet is connected to the top inlet of the feeding auger 8, and the feeding auger 8 is horizontally arranged on the lower part of the feeding bin 3, one end of the feeding auger 8 is connected with the motor 7, and the other end of the feeding auger 8 is exported Connect the flash dryer 9. When the motor 7 is running, the material in the feeding bin 3 is transported to the flash dryer 9 through the feeding auger 8 .

[0013] In the present invention, a sieve plate 4 and a permanent magnet 5 are provided in the feeding bin 3, so that the material achieves a bette...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap